Inner clip type formwork and matching apparatus thereof

An inner-clamping, formwork technology, applied in the direction of formwork/formwork/work frame, connection parts of formwork/formwork/work frame, and on-site preparation of building components, can solve the complex formwork construction process, waste of manpower, Material resources, waste of wood, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

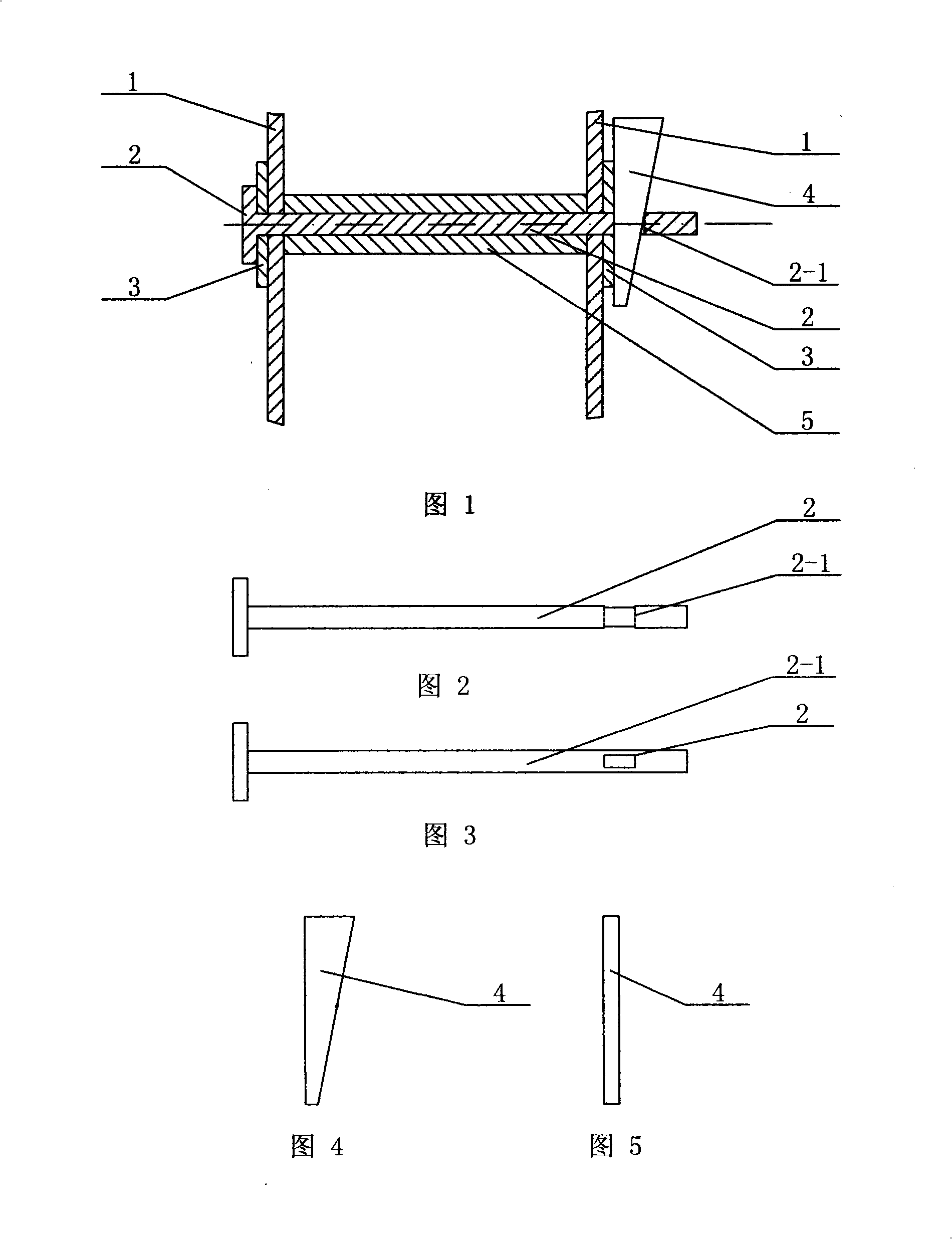

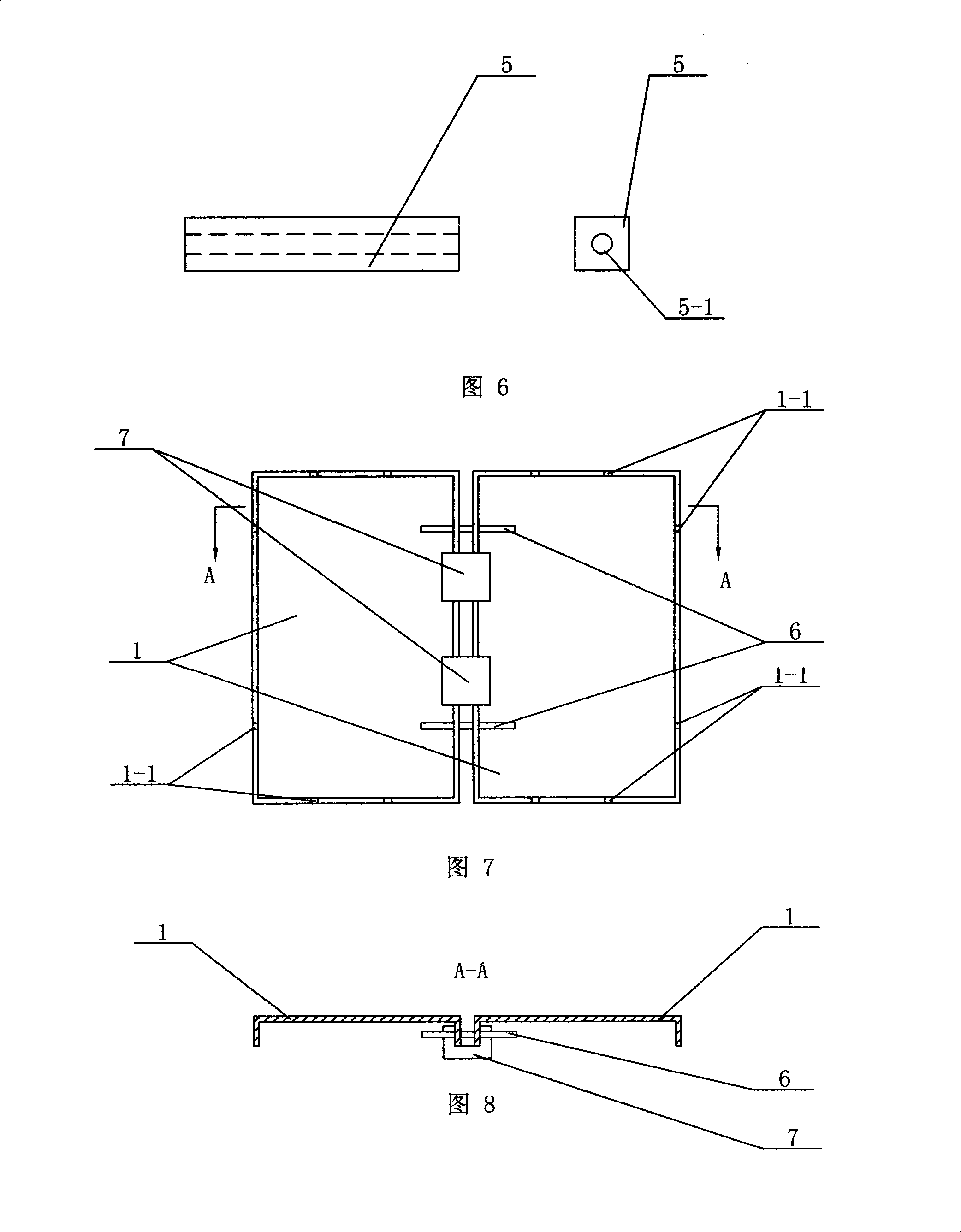

[0005] Referring to Figures 1-6, this embodiment adopts the following technical scheme: it consists of multiple templates 1, metal tie rods 2, gaskets 3, inserts with beveled edges 4, and prefabricated hollow concrete blocks 5, corresponding to two Metal tie rods 2 are interspersed between the templates 1, one end of the metal tie rods 2 is provided with a stopper 2-2, the other end of the metal tie rods 2 is provided with an insert slot 2-1, the stopper 2-2 at one end of the metal tie rods 2 and the template 1 A gasket 3 is arranged between them, and a gasket 3 is also arranged between the template 1 and the insert groove 2-1 at the other end of the metal tie rod 2, and the insert 4 is inserted into the insert groove 2-1 of the metal tie rod 2, The prefabricated hollow concrete block 5 is sleeved on the metal tie rod 2 and arranged between two templates 1 . In the present invention, a plurality of templates 1 are connected to form a large wall, and then two corresponding temp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com