Backlight system and light guide board with micro-optical structure

A backlight system and micro-optical technology, applied in the direction of light guide, optics, optical components, etc., can solve the problems of poor light-gathering effect and low utilization rate of light energy, and achieve the effect of reducing the number of components, reducing costs, and achieving high integration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] Below in conjunction with accompanying drawing and embodiment the utility model is further described.

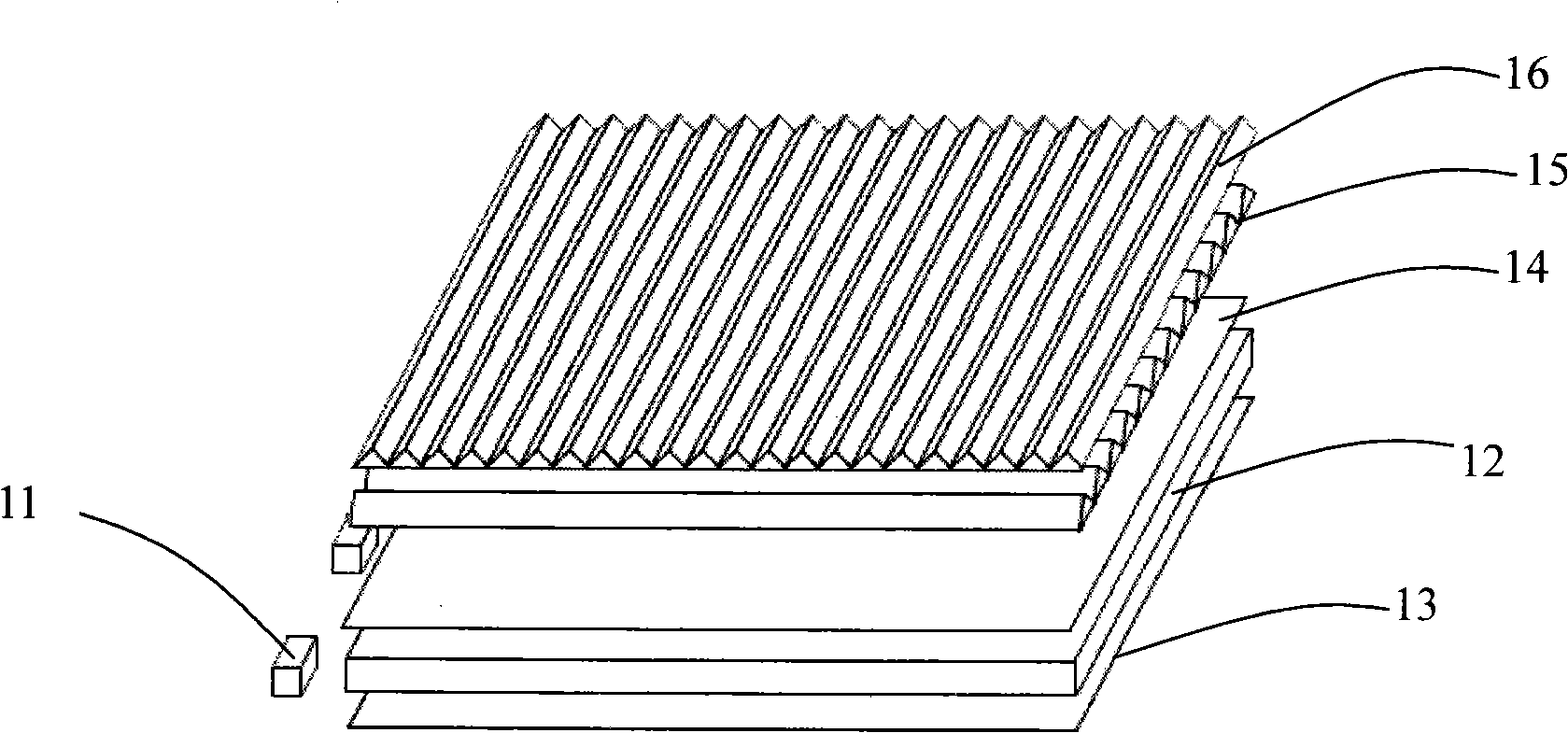

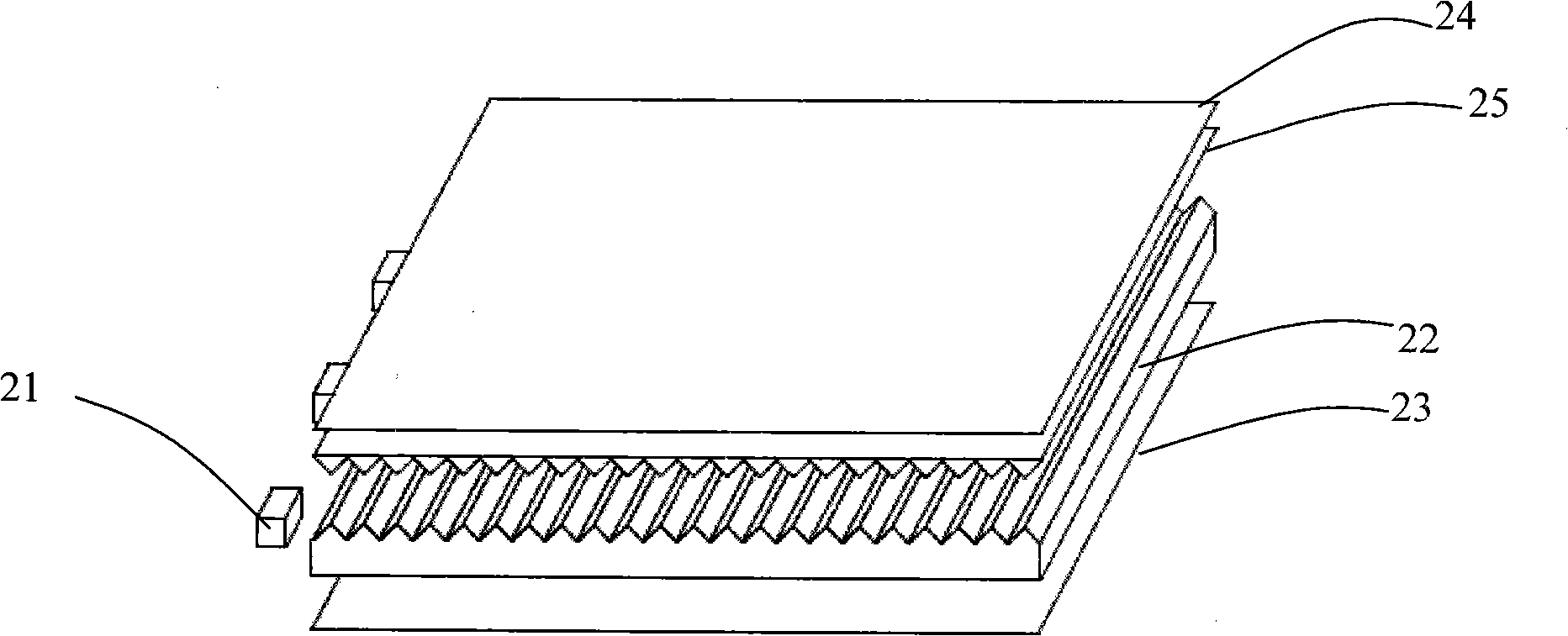

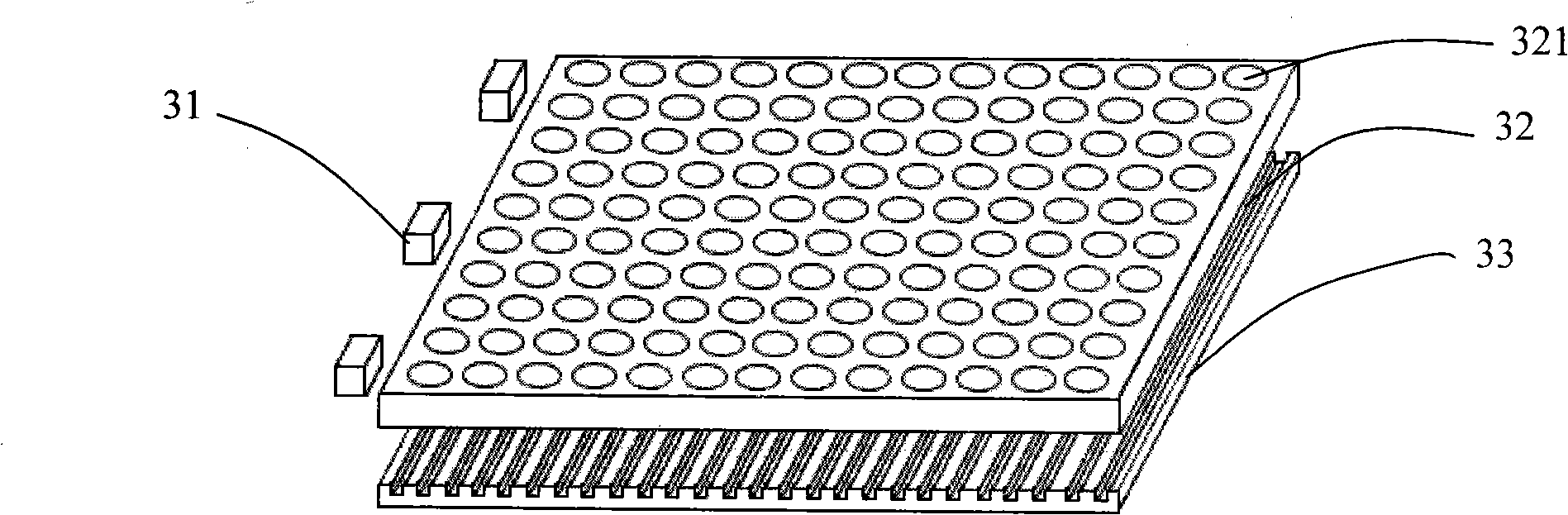

[0029] Such as Figure 3 ~ Figure 8 as shown, image 3 It is a structural schematic diagram of an embodiment of the present invention having a backlight system with a micro-optical structure and a light guide plate. The backlight system of this embodiment includes: a light source 31 , a light guide plate 32 and a reflection sheet 33 . Wherein, the light guide plate 32 includes a light incident surface for receiving the light emitted by the light source 31, a light exit surface for emitting the light, and a bottom surface opposite to the light exit surface, and a micro-optical light concentrating structure 321 is arranged on the light exit surface of the light guide plate 32. , Figure 4 That is, a structural schematic diagram of the micro-optical light-concentrating structure 321 having a concave region at the top, Figure 5 is a schematic cross-sectional view of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com