Technique for calendering mooring chain transom

A calendering process and mooring chain technology are applied in the field of mooring chain rung calendering device and calendering process to achieve the effects of reducing production costs, saving raw materials and improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

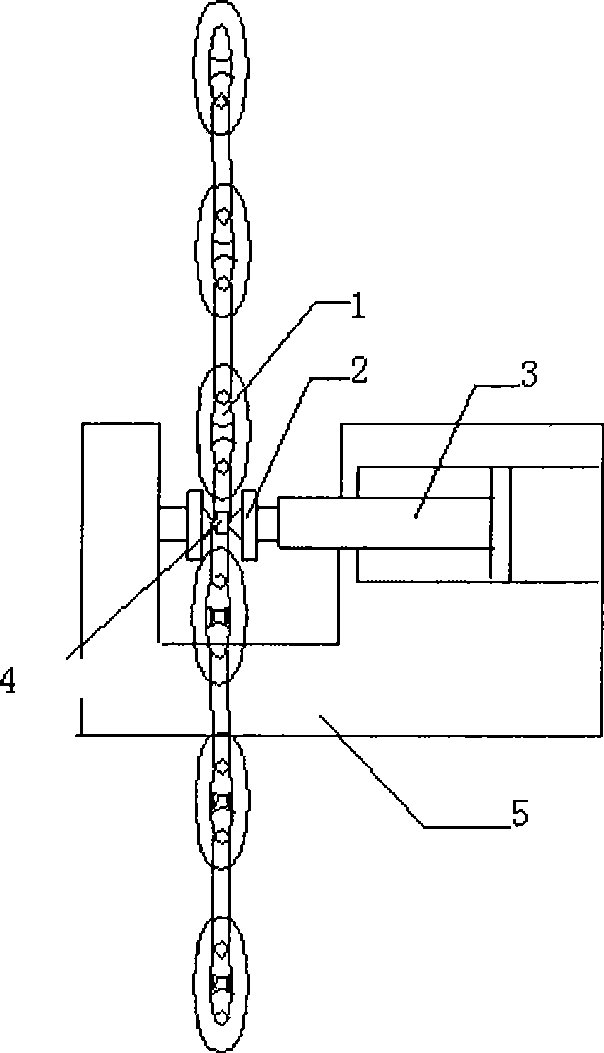

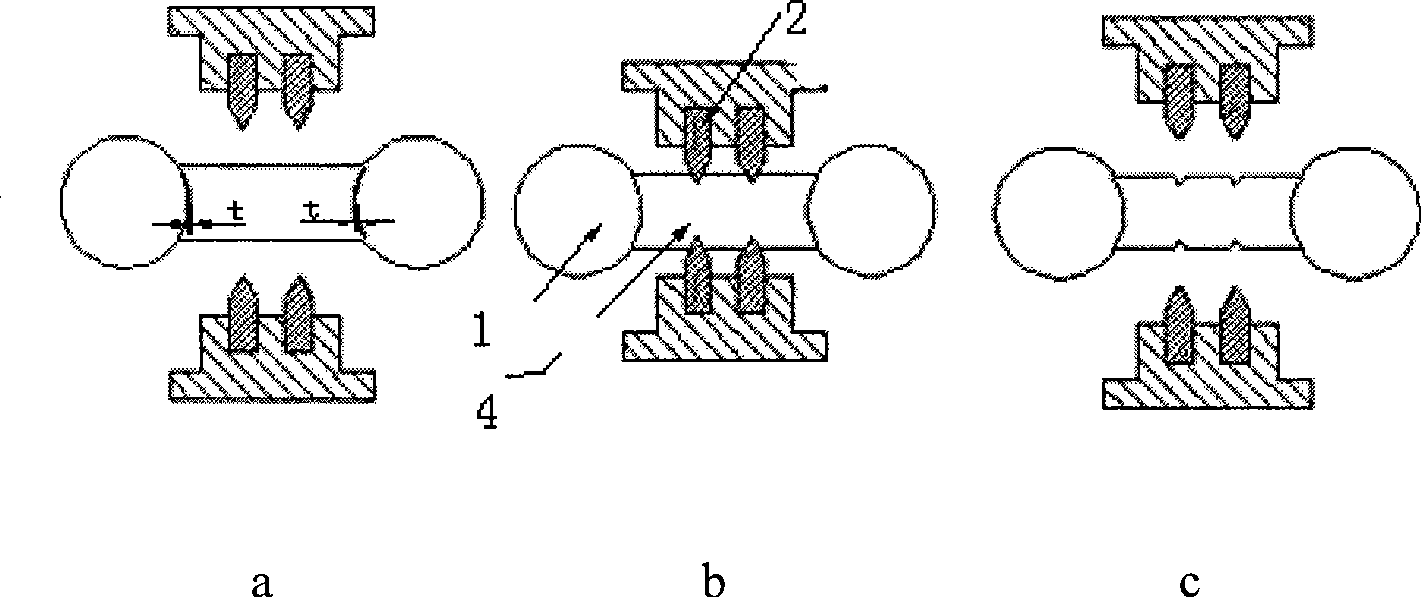

[0021] Embodiment 1: structure such as figure 1 , figure 2 As shown, a mooring chain transom rolling device includes a rolling die 2, an oil cylinder 3 and a body 5, the oil cylinder 3 is installed inside the body 5, and the calendering die 2 is connected to the piston rod of the oil cylinder 3.

[0022] Utilize above-mentioned mooring chain crosspiece calendering device to the technology of mooring chain crosspiece calendering as follows:

[0023] (1) Through the transmission mechanism, each link of the mooring chain passes through the calendering device in turn, and the positioning cylinders on both sides automatically position the links that need to be calendered;

[0024] (2) The crosspiece of the mooring chain is rolled by the calendering molds on both sides driven by the cylinder piston, so that the rolled crosspiece is extended and expanded longitudinally, so as to eliminate the gap between the two ends of the crosspiece and the ring body.

[0025] In the above-menti...

Embodiment 2

[0028] Embodiment 2: The mooring chain crosspiece calendering device and the main rolling process are the same as in Example 1, the difference is that in the mooring chain crosspiece calendering process, the pressure of the hydraulic system calendering is adjusted according to different product specifications, and the general control At 10-18MPA, such as R4∮76 mooring chain, when the crosspiece is rolled, the hydraulic system pressure is usually 10MPA.

Embodiment 3

[0029] Embodiment 3: The mooring chain crosspiece calendering device and the main rolling process are the same as in Example 1, the difference is that in the mooring chain crosspiece calendering process, the pressure of the hydraulic system calendering is adjusted according to different product specifications, and the general control At 10-18MPA, such as R4∮111 mooring chain, when the crosspiece is rolled, the hydraulic system pressure is usually 18MPA.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com