Edible fungus culture material bagging device

A technology for bagging and edible fungi is applied in the field of bagging machines that can adjust the bagging tightness of edible fungi culture material, and can solve the problems of being unsuitable for small and medium-sized edible fungi manufacturers, complex equipment structure, and low processing cost. , to achieve the effect of simple structure, high work efficiency and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The present invention will be further described below in conjunction with the accompanying drawings.

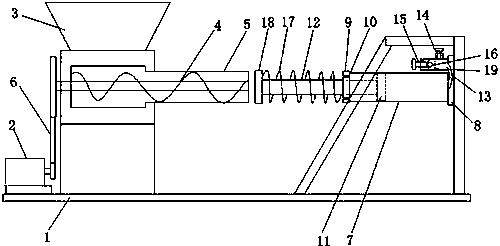

[0011] Such as figure 1 As shown, the edible mushroom culture material bagging device of the present invention includes a frame 1, a motor 2, a hopper 3, a screw propeller 4, a material guiding cylinder 5, and an air damping pressurizer. The hopper 3 is arranged on the top of the screw propeller 4, the material guide cylinder 5 is arranged on the end of the screw propeller 4, and the air damping pressurizer is arranged on the frame 1 opposite to the material guide cylinder 5, and the air damping pressurizer The outlet of top plate 18 and material guide tube 5 has a slight spacing, which can make material guide tube 5 be put on plastic bag easily. The screw propeller 4 is driven by the motor 2 through the belt 6, and the culture material is pushed into the plastic bag on the material guide cylinder 5 through the material guide cylinder 5. Described air damping pressur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com