Novel mining single ring tempering method

A high-strength, circular chain technology, used in heat treatment equipment, furnaces, heat treatment furnaces, etc., can solve the problems of far-flung temperature distribution, single-ring current burns, and lack of differential temperature tempering, so as to improve quality and The effect of job reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

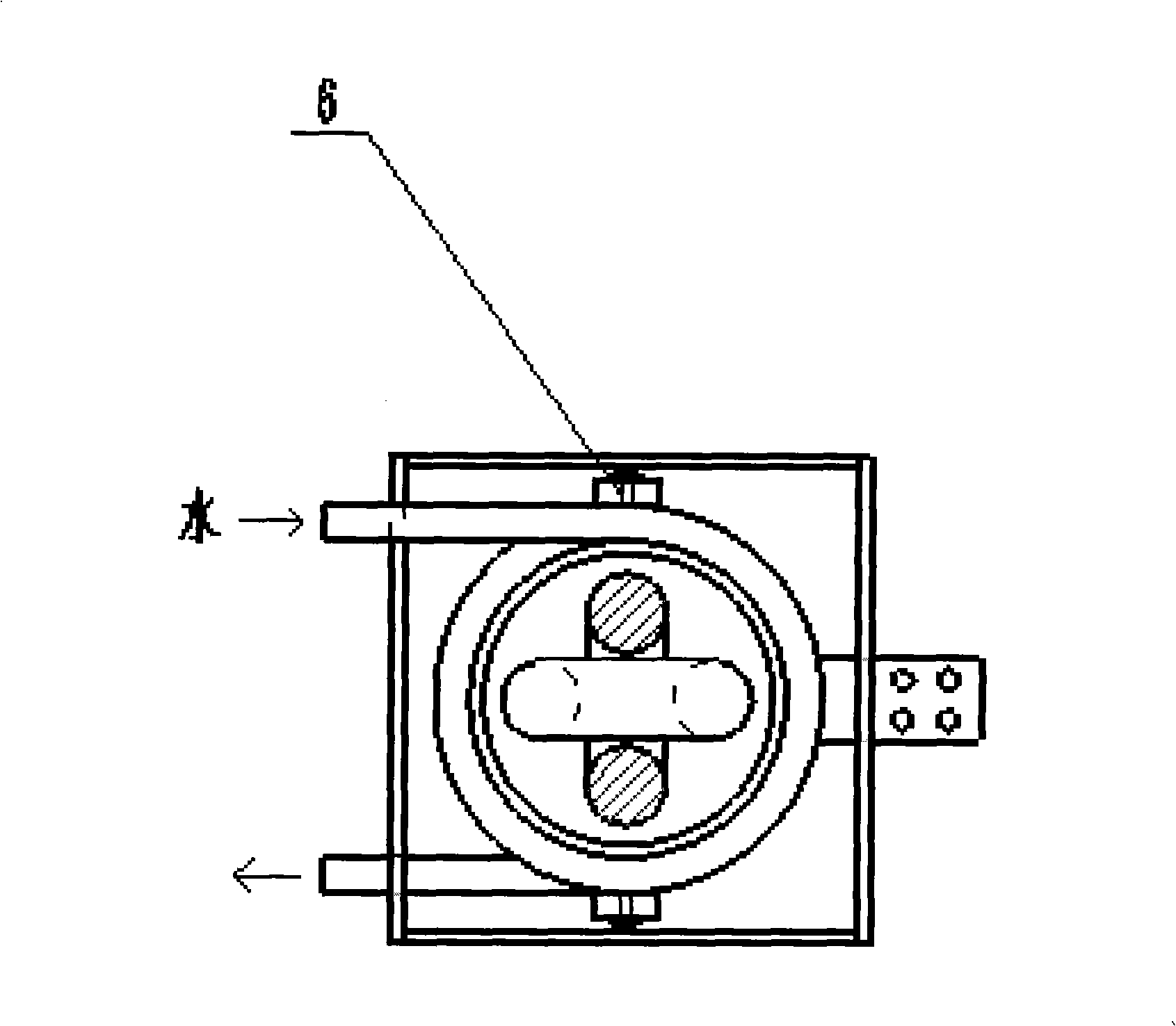

[0014] During heat treatment, the single ring to be tempered in the chain is placed in the middle of the induction coil. If the inductance of the inductor is not enough during heating, an unloaded inductor can be connected in series. The heating temperature should be the same as that of the differential temperature tempering process for chains of the same specification.

[0015] Example of single-ring differential temperature tempering

[0016] The method of medium frequency induction heating is used to carry out differential temperature tempering on the 30×108 high-strength D-grade circular link for mining. The single-loop tempering sensor consists of a Φ20mm round copper tube that is tightly wound clockwise into a solenoid coil. The single-loop height of the 30×108 chain is 168mm, the maximum outer width is 98mm, and the effective number of turns of the inductor coil is 4 turns. , between turns and turns with 2mm thick mica sheet insulation. The inner diameter of the induc...

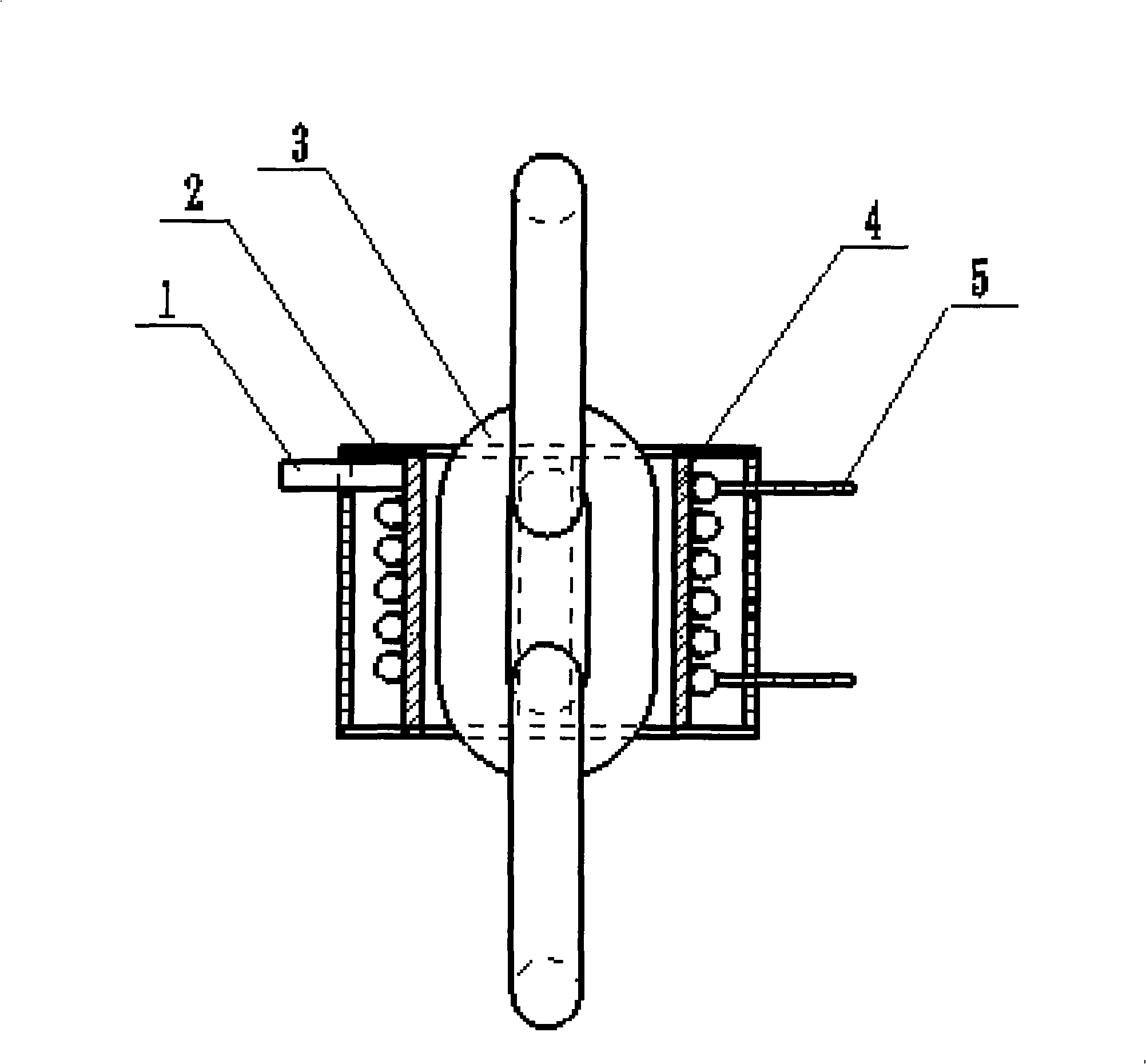

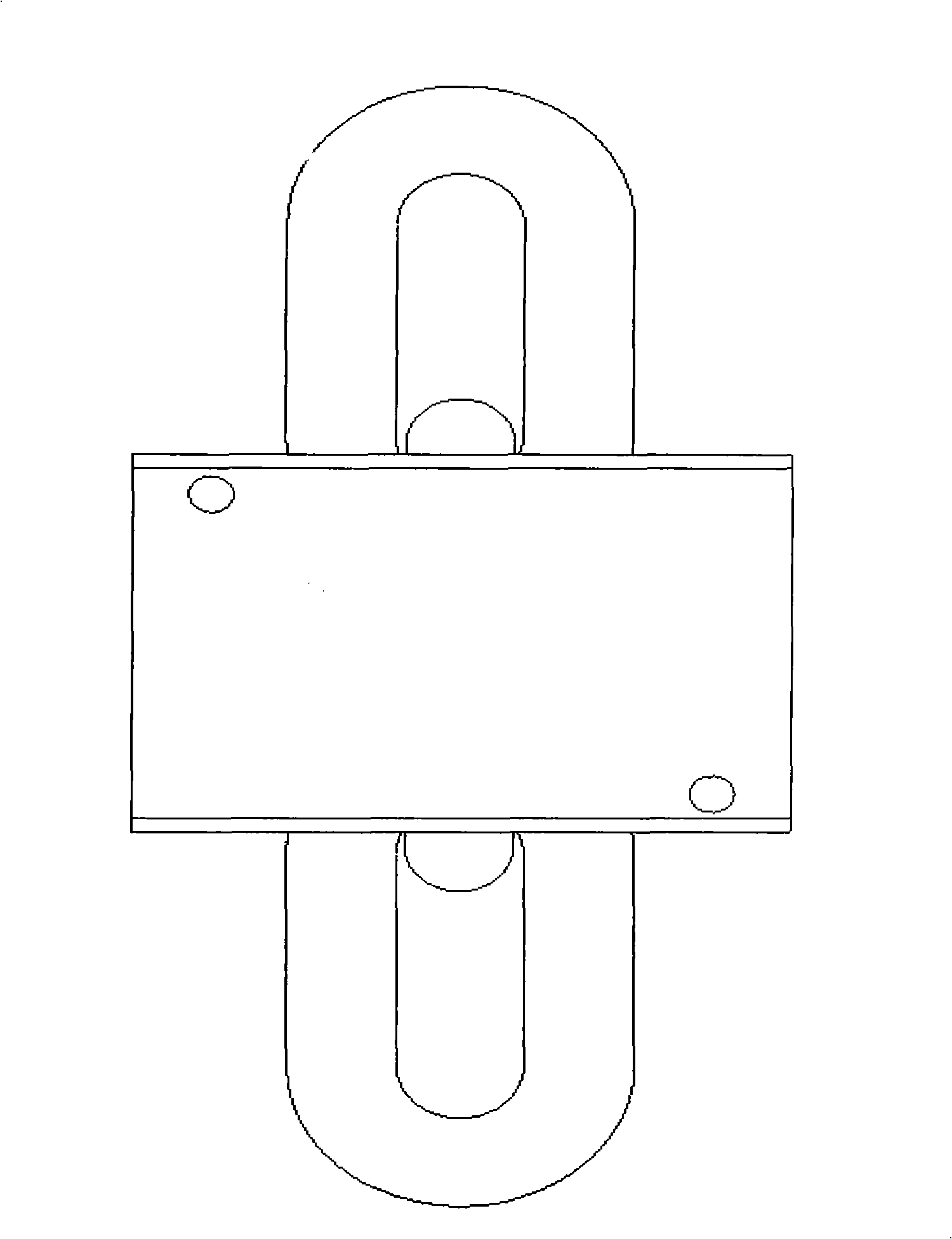

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com