Drum-type washing machine

A drum washing machine and drum technology, which is applied to other washing machines, washing machines with containers, control devices of washing machines, etc., can solve the problems of odor, reduce washing performance of drum washing machines, pollution, etc. Effect of washing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] Hereinafter, the structure and function of an embodiment of the present invention will be described in detail with reference to the accompanying drawings. The following description is a part of several aspects in this patentable invention.

[0032] In the process of describing the present invention, in order to clarify the technical idea of the present invention more clearly, relevant specific descriptions for known functions or structures will be omitted.

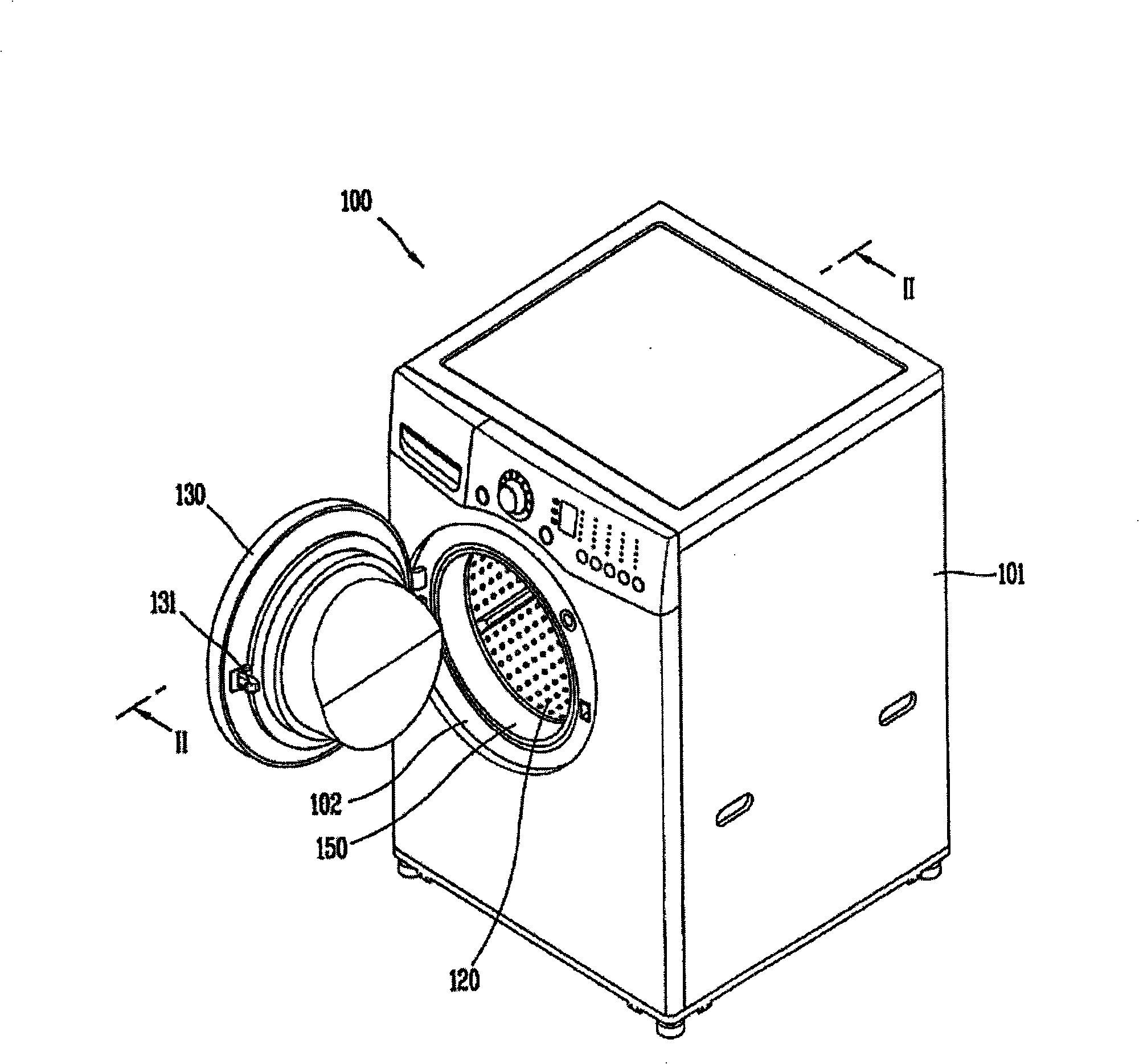

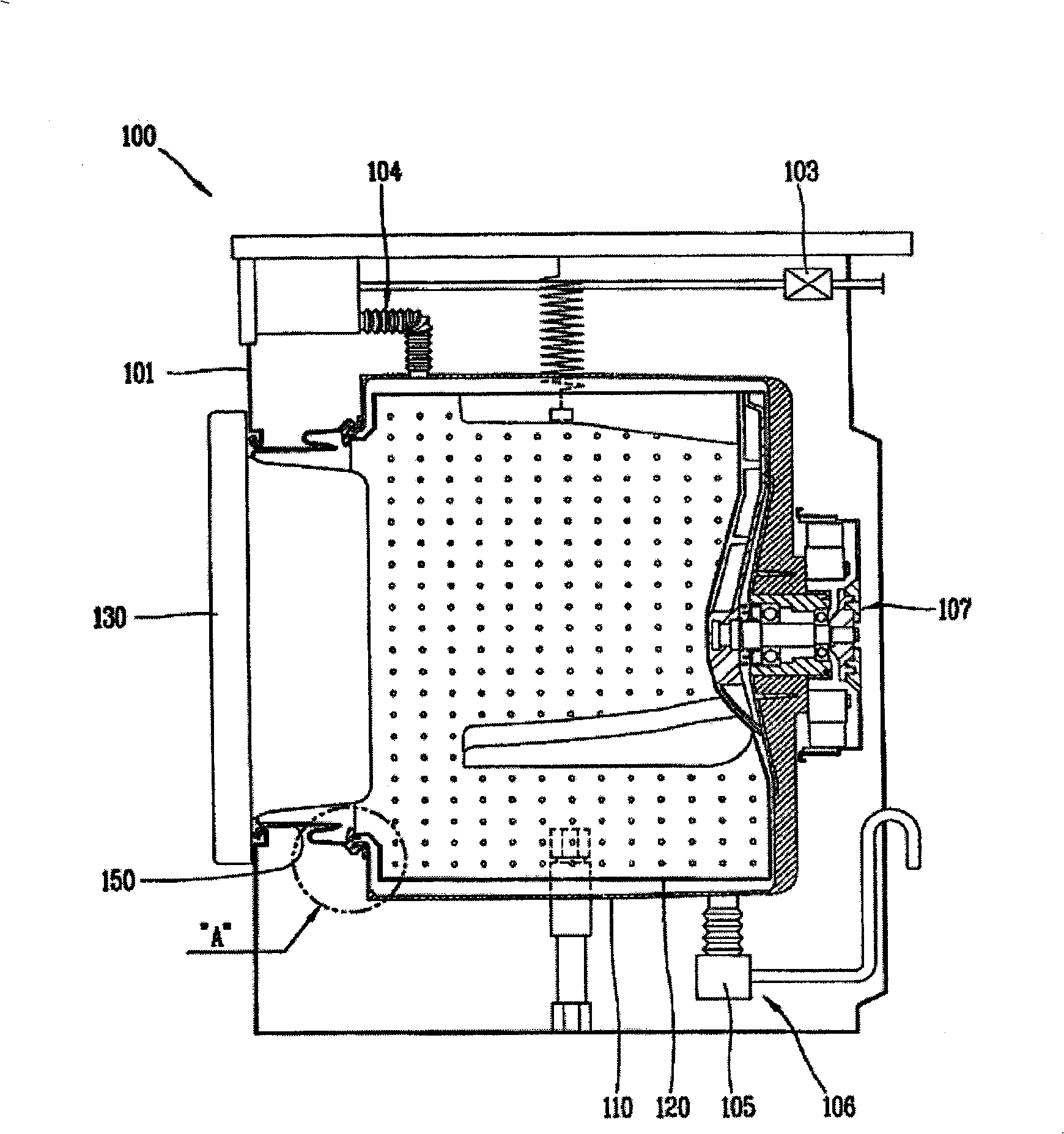

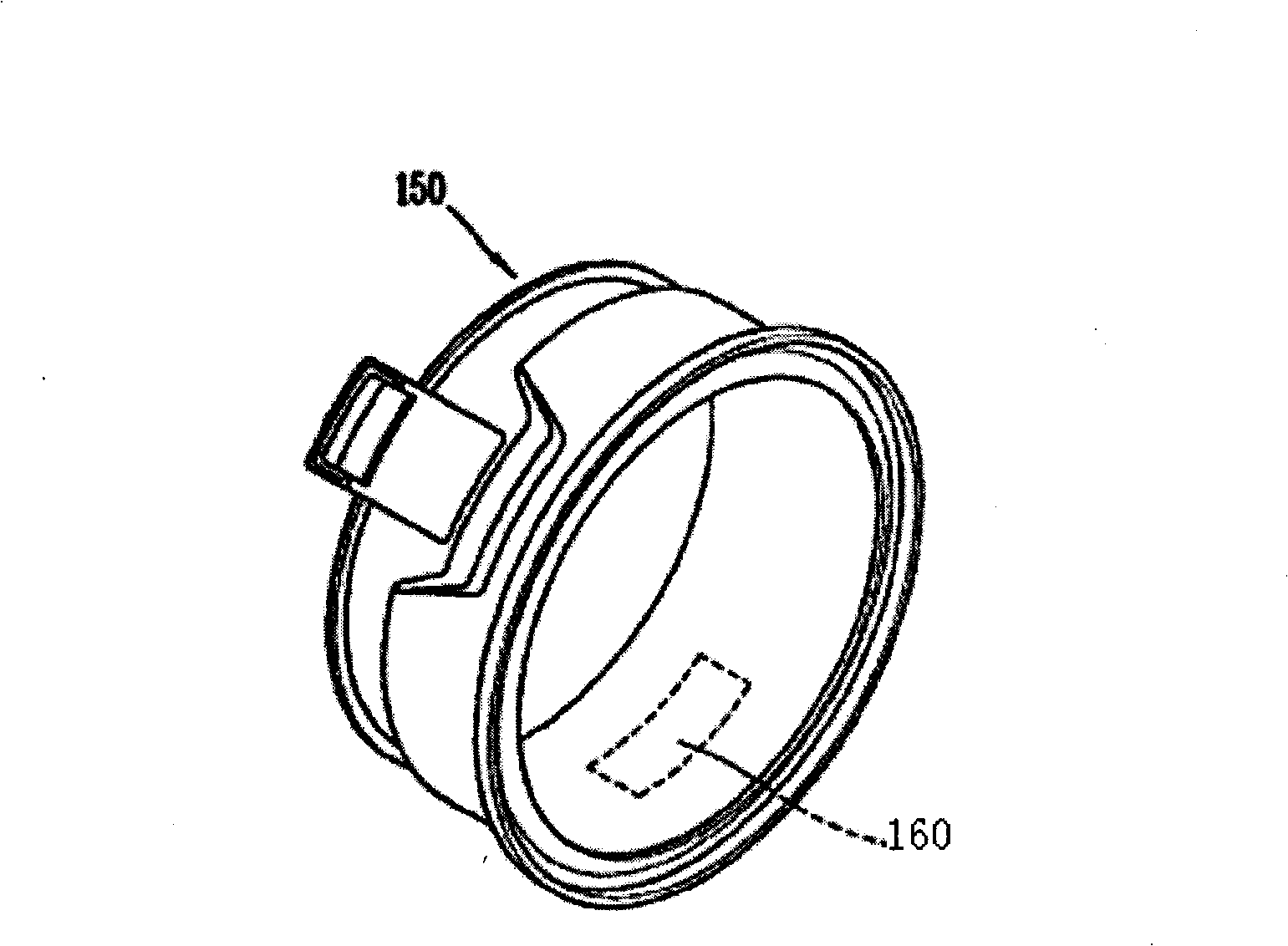

[0033] figure 1 It is a perspective view of the drum washing machine in the present invention; figure 2 yes figure 1 The cross-sectional view of the cut-off line II-II in; image 3 yes figure 2 Perspective view of the gasket in .

[0034] Refer to attached figure 1 and attached figure 2 , the drum washing machine 100 in the present invention includes the following parts: a housing 101 formed with an inlet 102 for putting in laundry; a door 130 for opening and closing the inlet 102; The inner side of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com