Vibrating isolation foundation precise leveling system

A vibration isolation platform and foundation technology, applied in infrastructure engineering, protection devices, buildings, etc., can solve the problems of inability to achieve high-precision flatness, unreachable, large area, etc., to protect normal operation and solve the problem of virtual legs , the effect of maintaining system stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

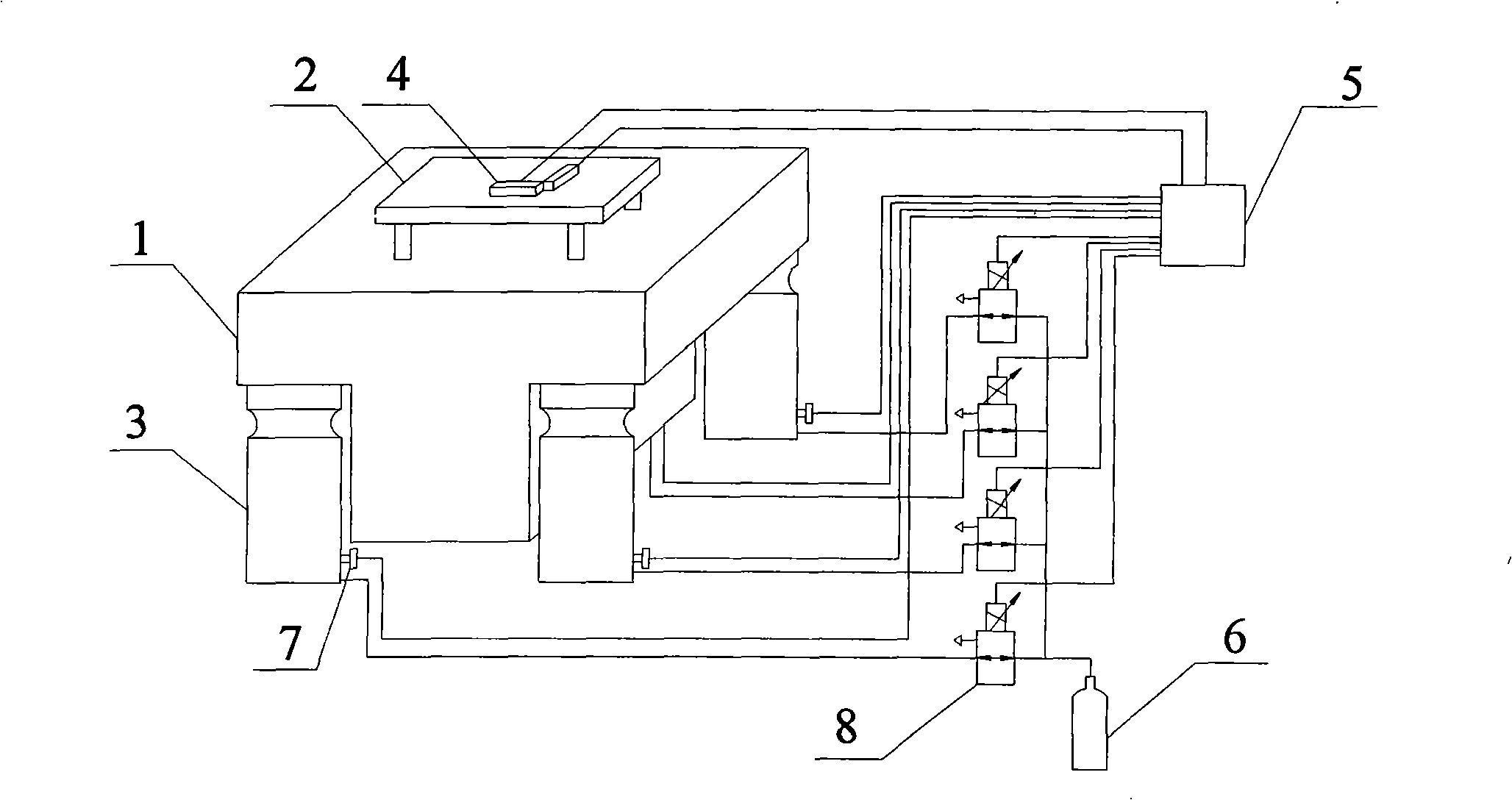

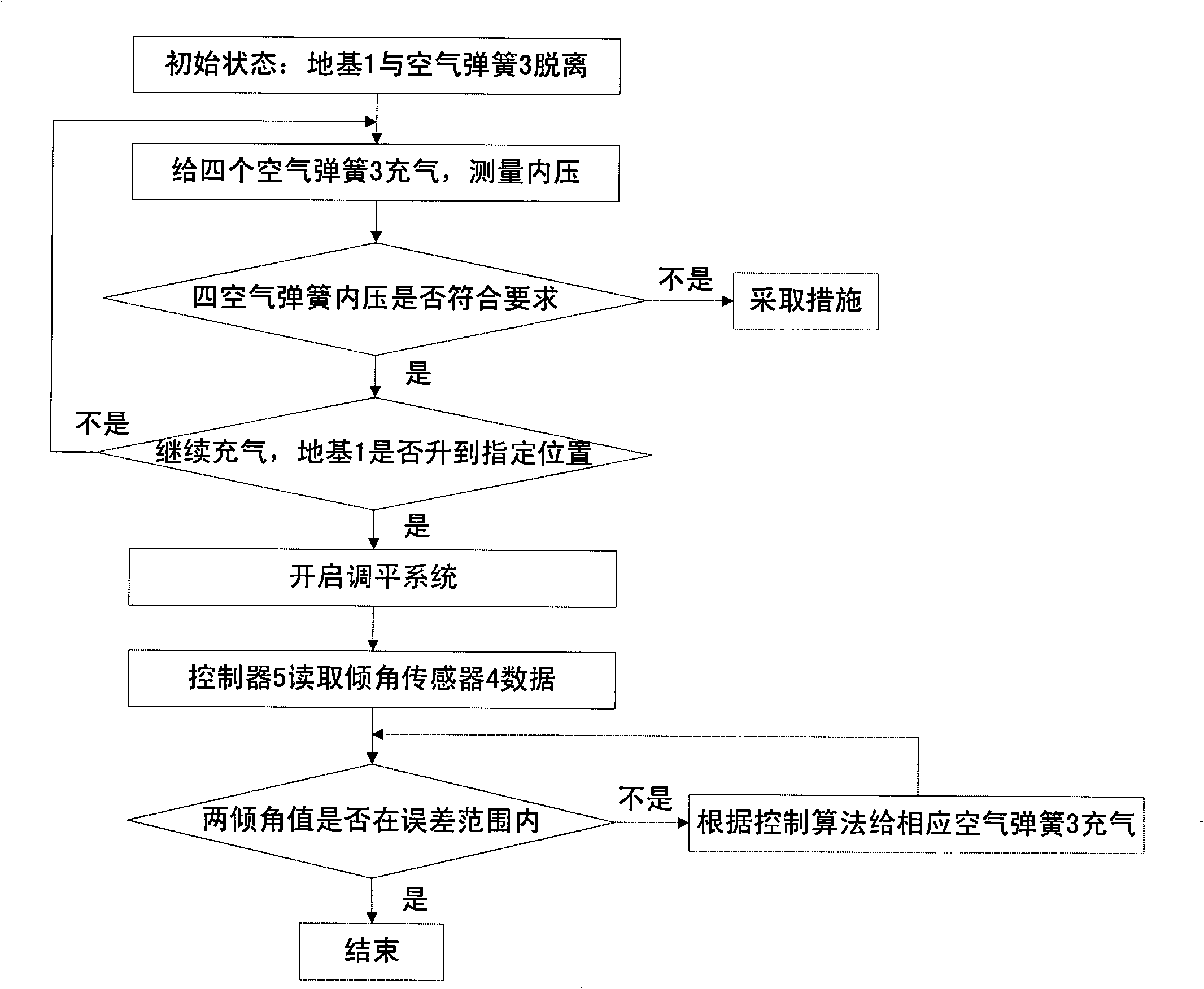

[0026] Such as figure 1 As shown, the present invention includes a vibration isolation foundation 1, a damping precision optical vibration isolation platform 2, four air springs 3, an air supply device 6, a level monitor, a virtual leg monitoring device, a controller 5 and a control valve; the vibration isolation foundation 1 The four corners of the bottom surface are respectively supported by four air springs 3. The damped precision optical vibration isolation platform 2 is placed on the vibration isolation foundation 1, and two damped precision optical vibration isolation platforms 2 are placed on it to measure two mutually perpendicular The level monitor of the angle between the precise optical vibration isolation platform and the absolute horizontal plane in the direction, the "virtual leg" monitoring device is connected to the respective air spring 3, and the output terminals of the level monitor and the virtual leg monitoring device are respectively connected to the contr...

Embodiment 2

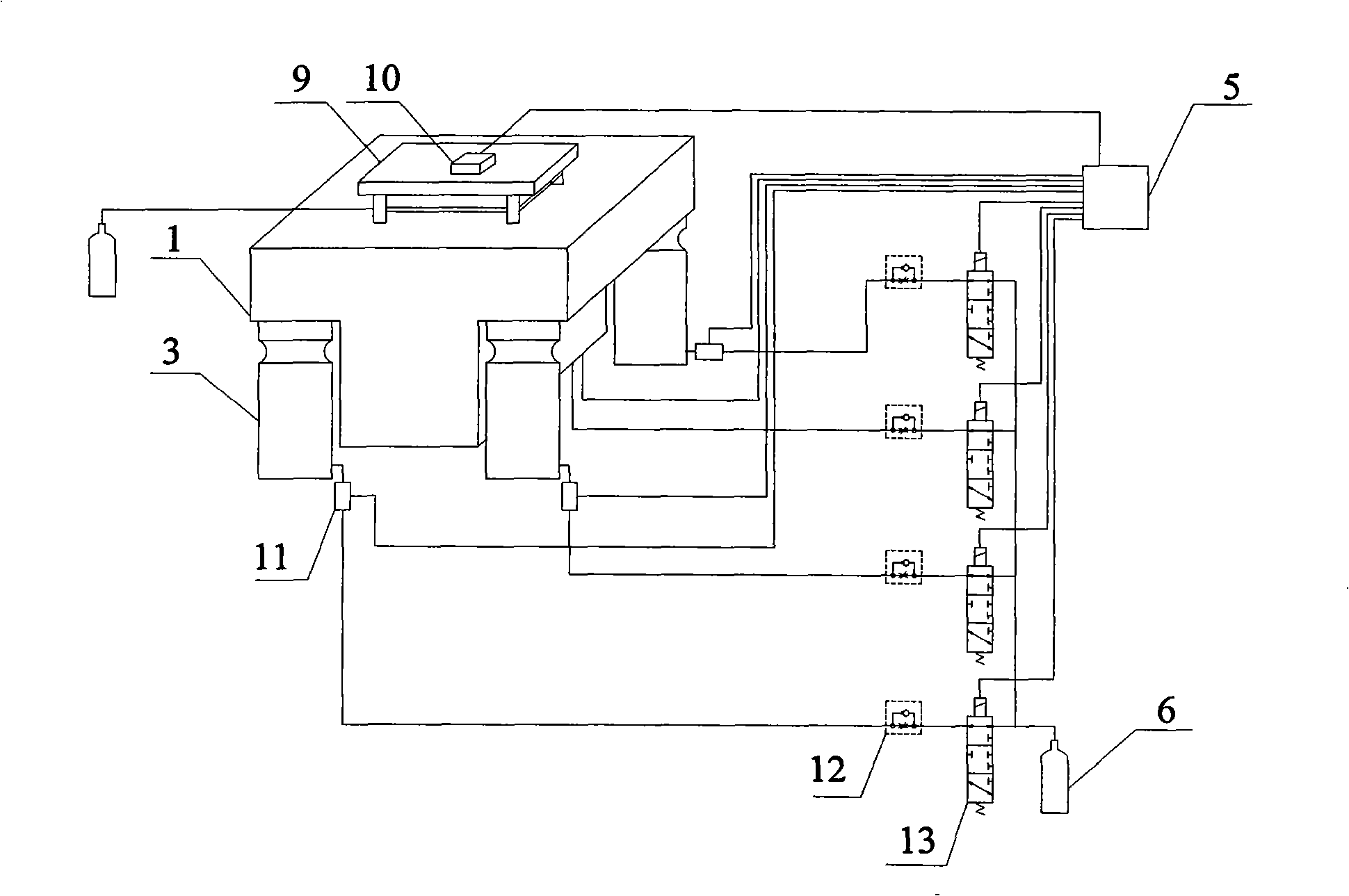

[0032] Such as figure 2 As shown, the present invention includes a vibration isolation foundation 1, an air cushion type precision optical vibration isolation platform 9, four air springs 3, an air supply device 6, a level monitor, a virtual leg monitoring device, a controller 5 and a control valve; the vibration isolation foundation 1. The four corners of the bottom surface are respectively supported by air springs 3. The air-cushion type precision optical vibration isolation platform 9 is placed on the vibration isolation foundation 1, and two air-cushion type precision optical vibration isolation platforms 9 are placed on it to measure two vertical directions. The level monitor of the angle between the vibration isolation platform and the absolute horizontal plane, and the virtual leg monitoring device are respectively connected to the respective air springs 3, and the output ends of the level monitor and the virtual leg monitoring device are respectively connected to the i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com