Flexible plastic film solar energy hot water apparatus

A solar water heater and soft plastic technology, which is applied in the field of heating, can solve the problems of limiting the area and installation form of the collector, fragile glass tubes of the collector, and unable to fully utilize the thermal energy, etc., and achieves convenient laying and connection, low price, and difficulty in laying and connecting. broken effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

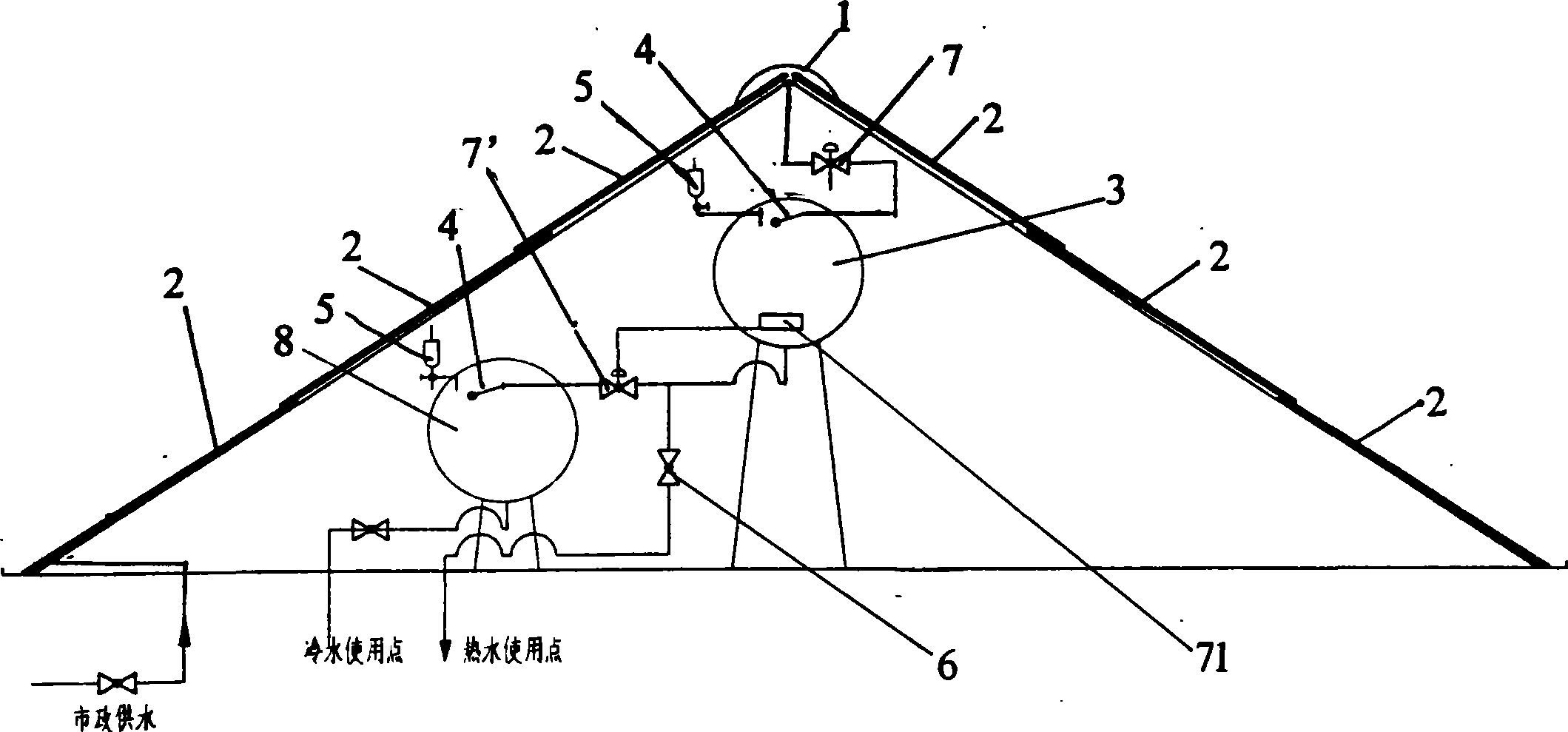

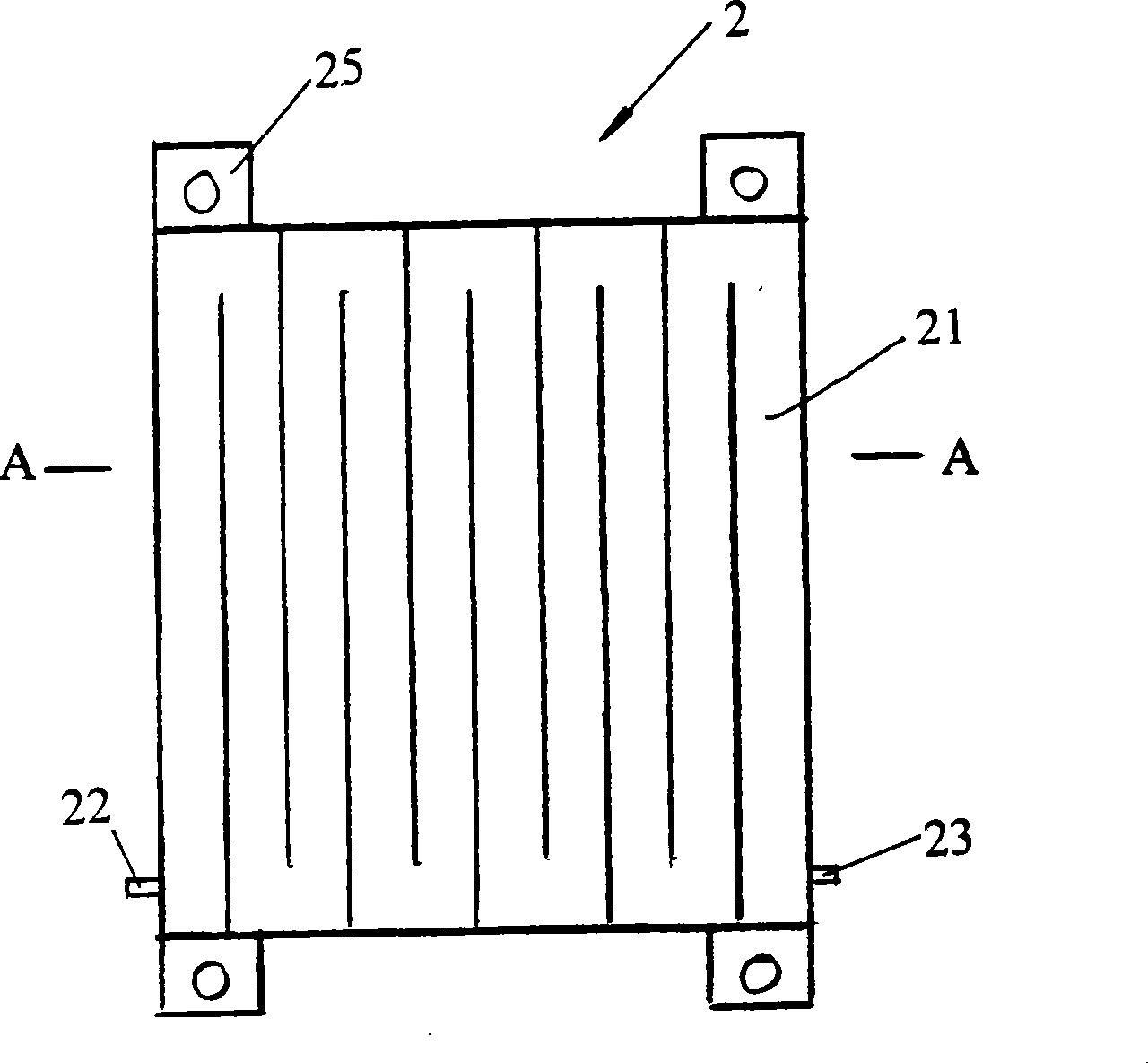

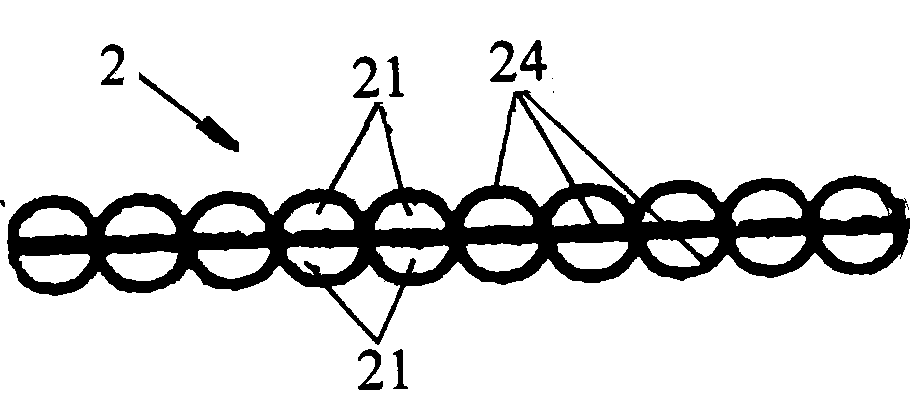

[0021] see figure 1 As shown, it is a schematic diagram of a structural form provided on a sloping roof for the present invention, which includes a heat collector, a hot water tank 3 and a self-operated temperature control valve 7, which is the same as the existing solar water heater hot water tank 3 and self-operated The temperature control valve 7 is basically the same, and the difference is that the heat collector of the present invention is made up of at least two or more soft plastic film heat collection units 2, and this soft plastic film heat collection unit 2 (see figure 2 with image 3 ) is a hollow body formed by thermal welding of 3 or 4 layers of linear low-density polyethylene (LLDPE) or high-density polyethylene (HDPE) or polypropylene (PP) soft plastic film 24 stacked up and down. A zigzagging path 21 is formed between every two layers of soft plastic films 24 adjacent to each other. In this way, two layers of zigzagging paths 21 are formed in the hollow bodie...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com