Fabric three-dimensional pressure simulation test system

A simulation test, three-dimensional pressure technology, applied in textile testing, measuring force, measuring device and other directions, can solve the problems of complex operation, difficult control, clothing deformation, etc., to achieve the effect of process parameter optimization, convenient operation and simple mechanism

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further explained below in conjunction with specific embodiments. It should be understood that these embodiments are only used to illustrate the present invention and not to limit the scope of the present invention. In addition, it should be understood that after reading the teachings of the present invention, those skilled in the art can make various changes or modifications to the present invention, and these equivalent forms also fall within the scope defined by the appended claims of this application.

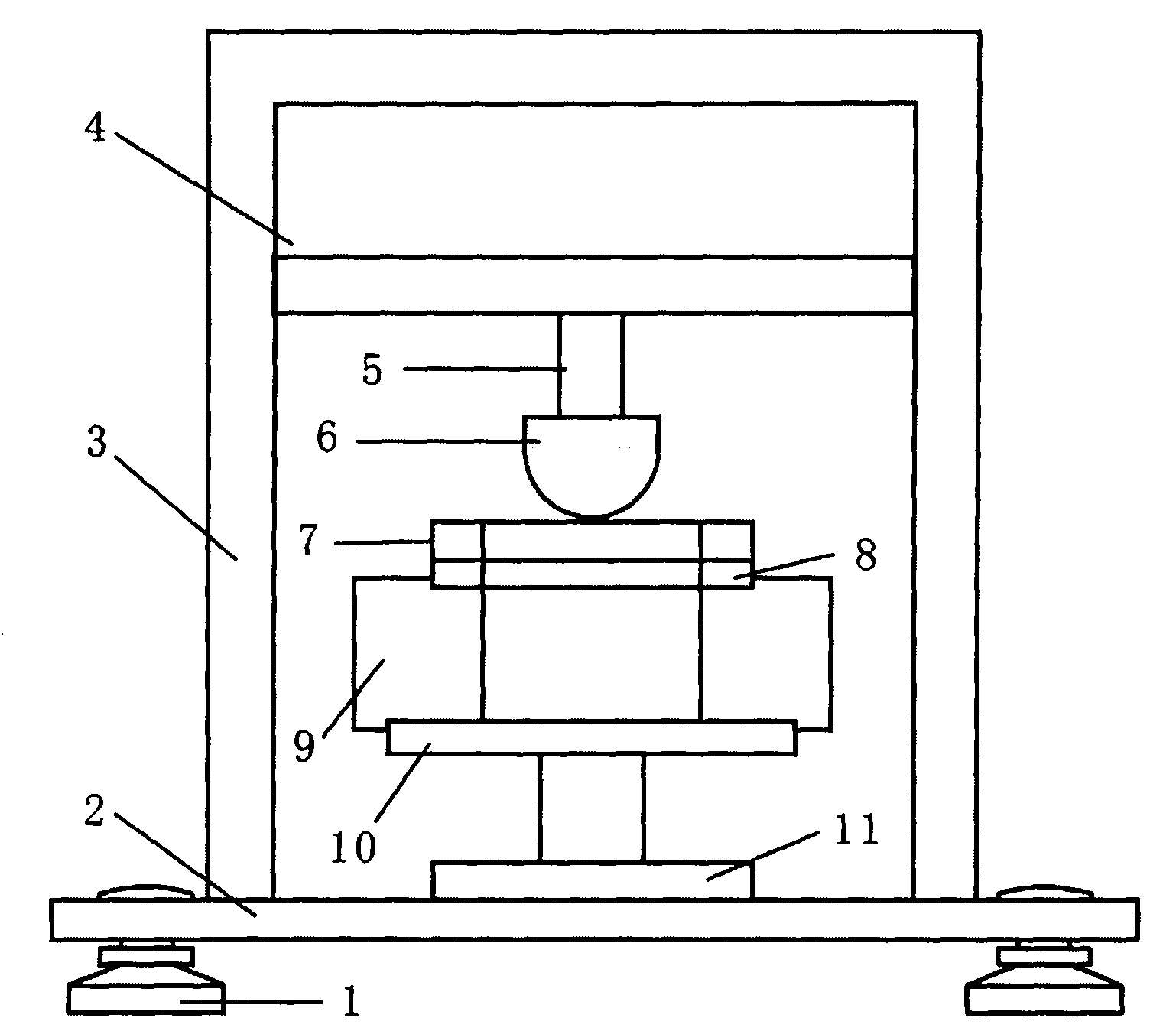

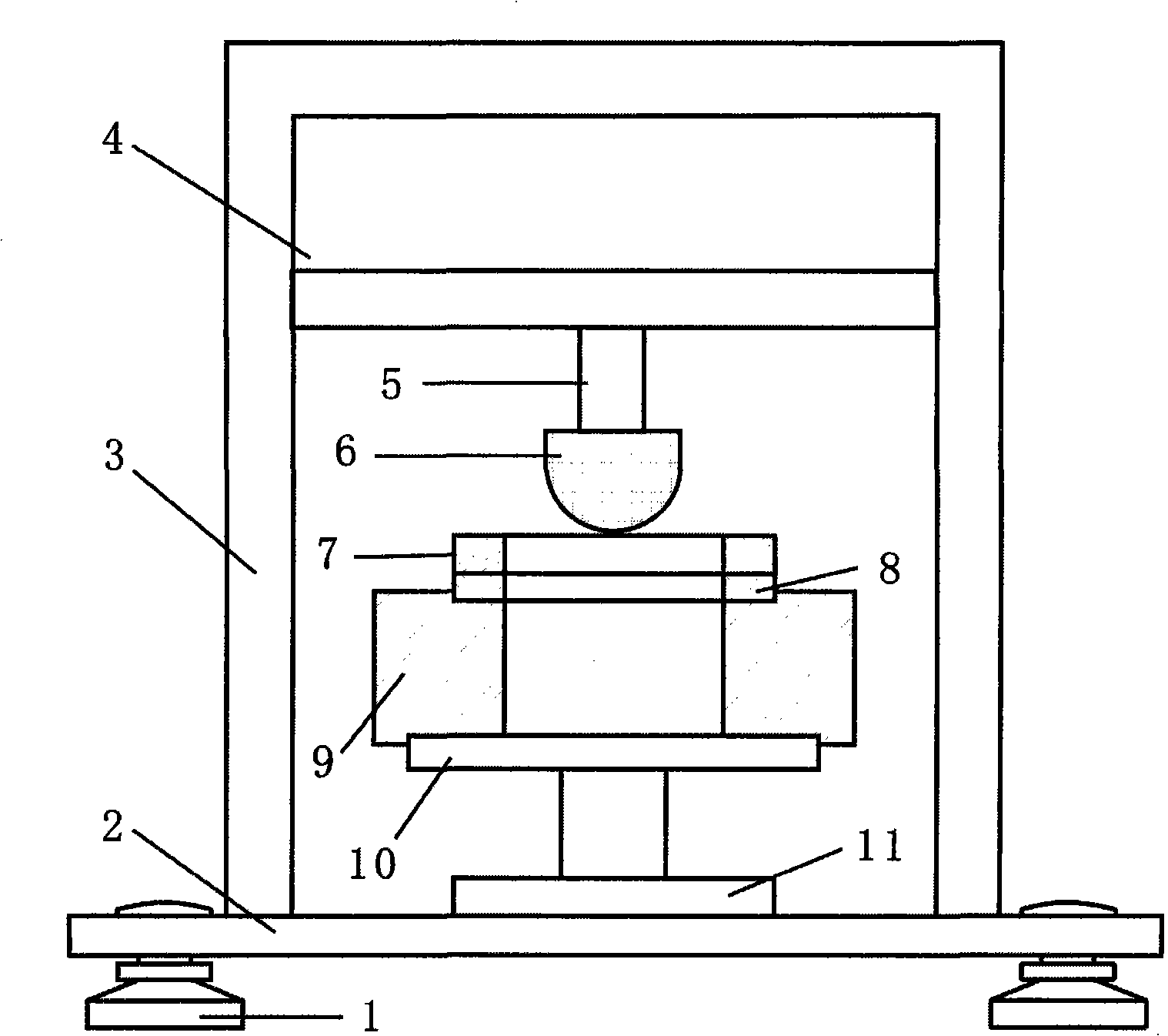

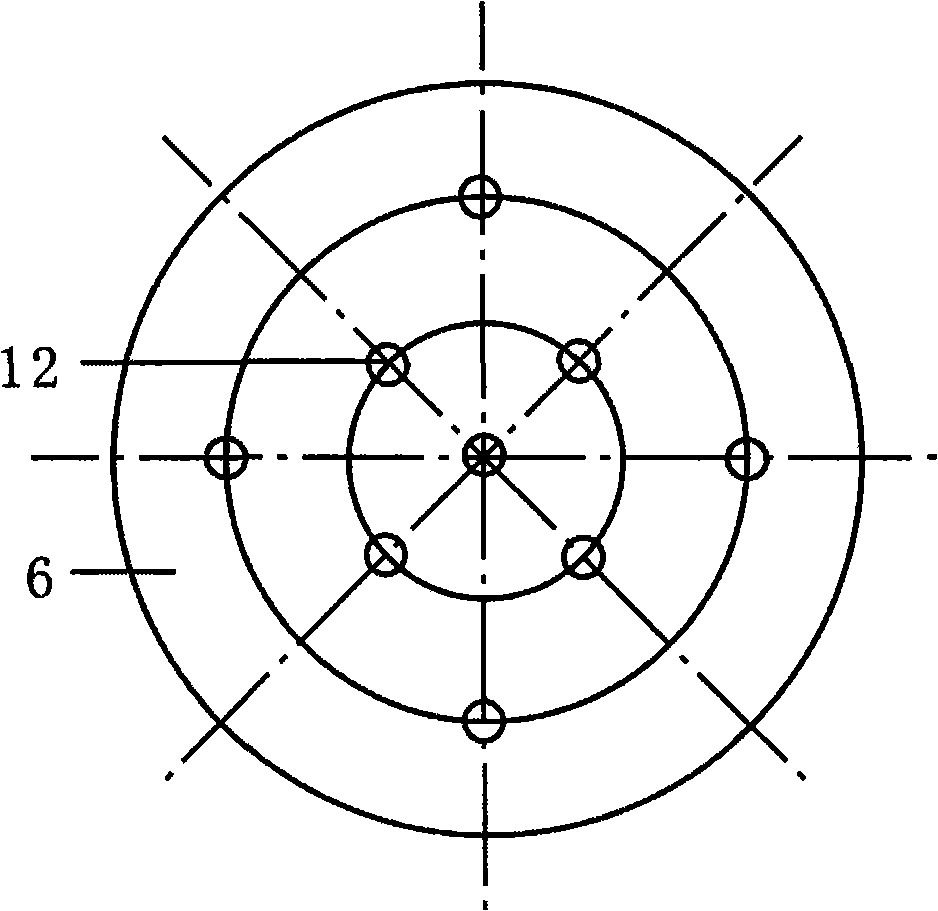

[0031] The appearance structure of the present invention is shown in Fig. 1, where the main frame adopts a double-screw gantry structure, which has a large operating space, a wide range of force measurement, and a stable and reliable action. The transmission part is driven by a set of 400W imported AC servo system to drive the timing belt wheel, and then two lead screws are driven by the timing belt to control the reciprocating movement of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com