Ultra-deep foundation pit support non-intermittent composite transfer structure and construction method

A construction method and non-intermittent technology, which can be used in infrastructure engineering, excavation, construction, etc., can solve problems such as excessive deformation of the enclosure structure, reduce building energy consumption, improve structural construction efficiency and structural safety, and improve stability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be further described in detail below with reference to the accompanying drawings and examples. The following examples are explanations of the present invention and are not limited to the following examples.

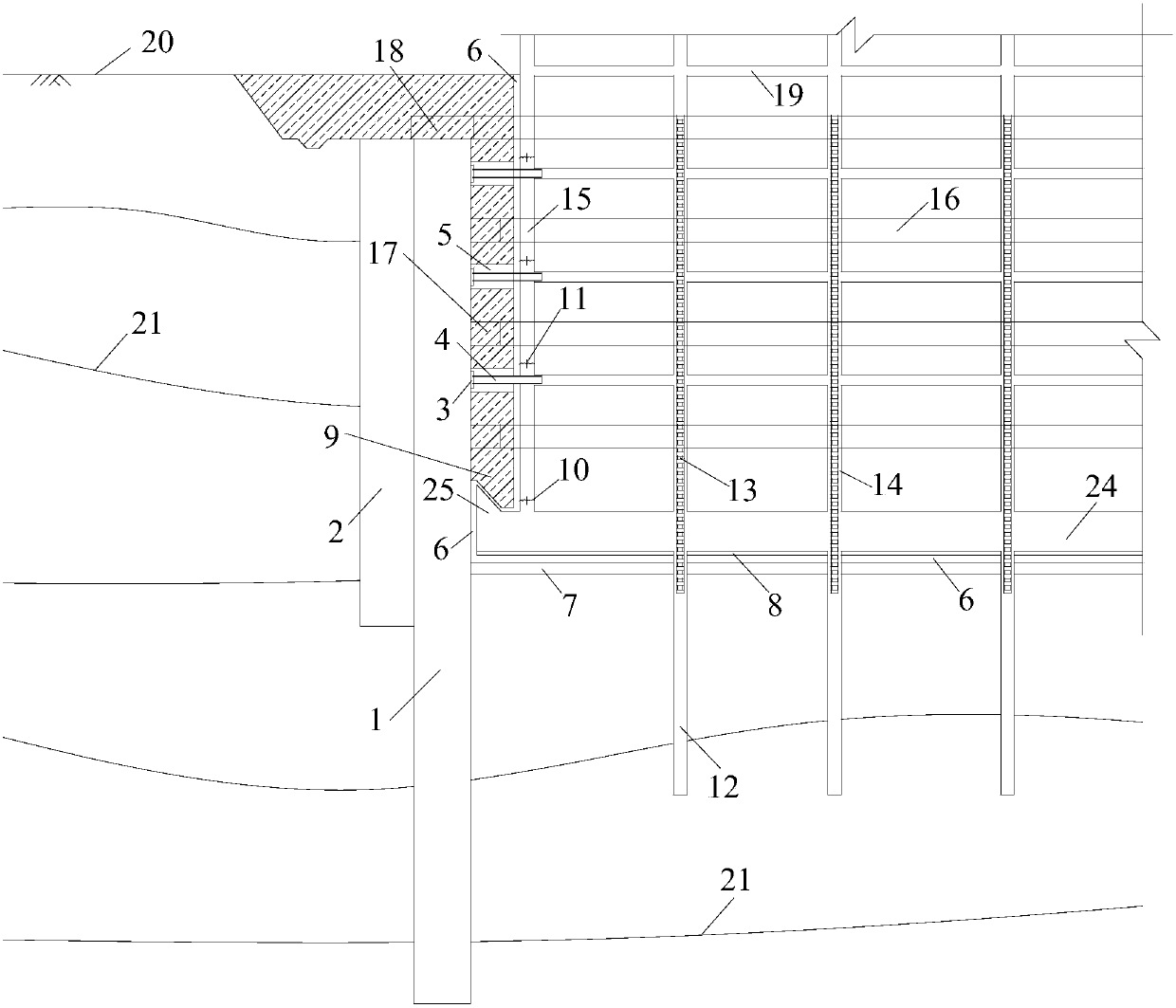

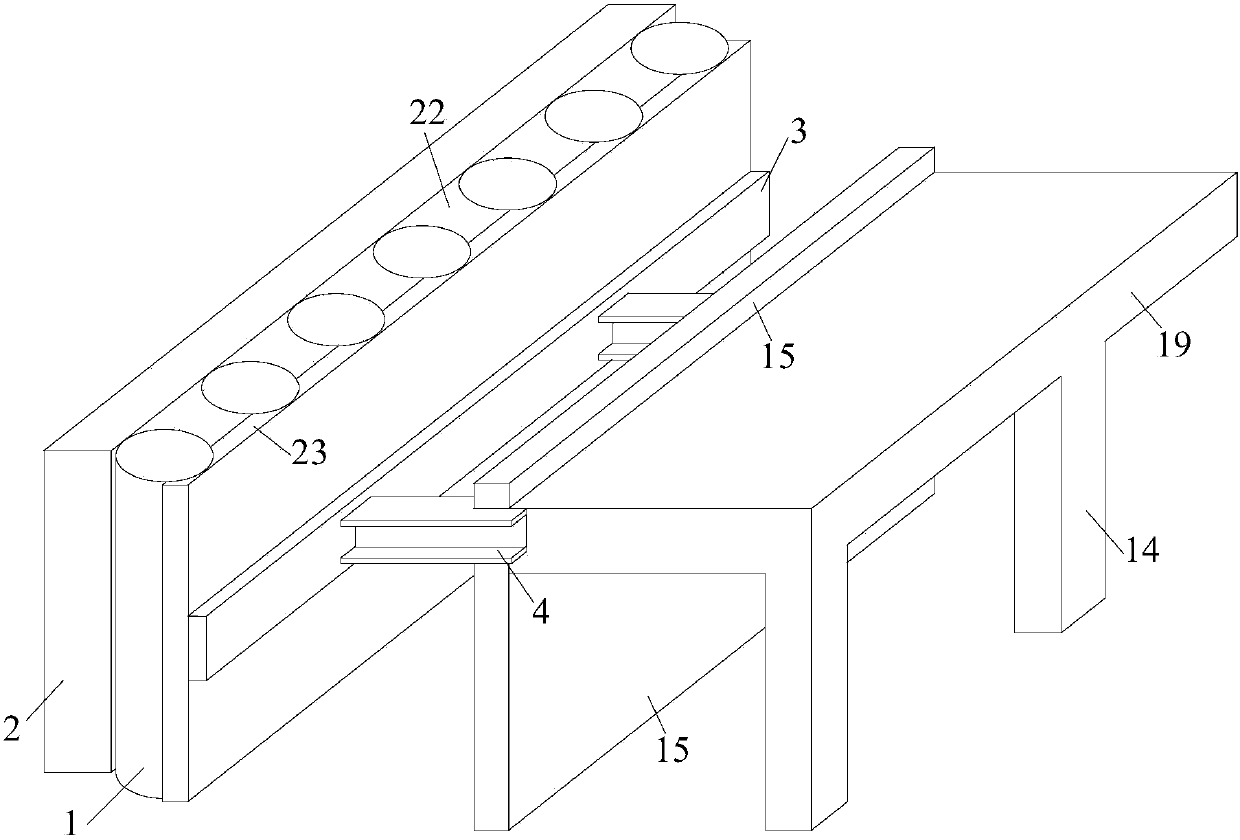

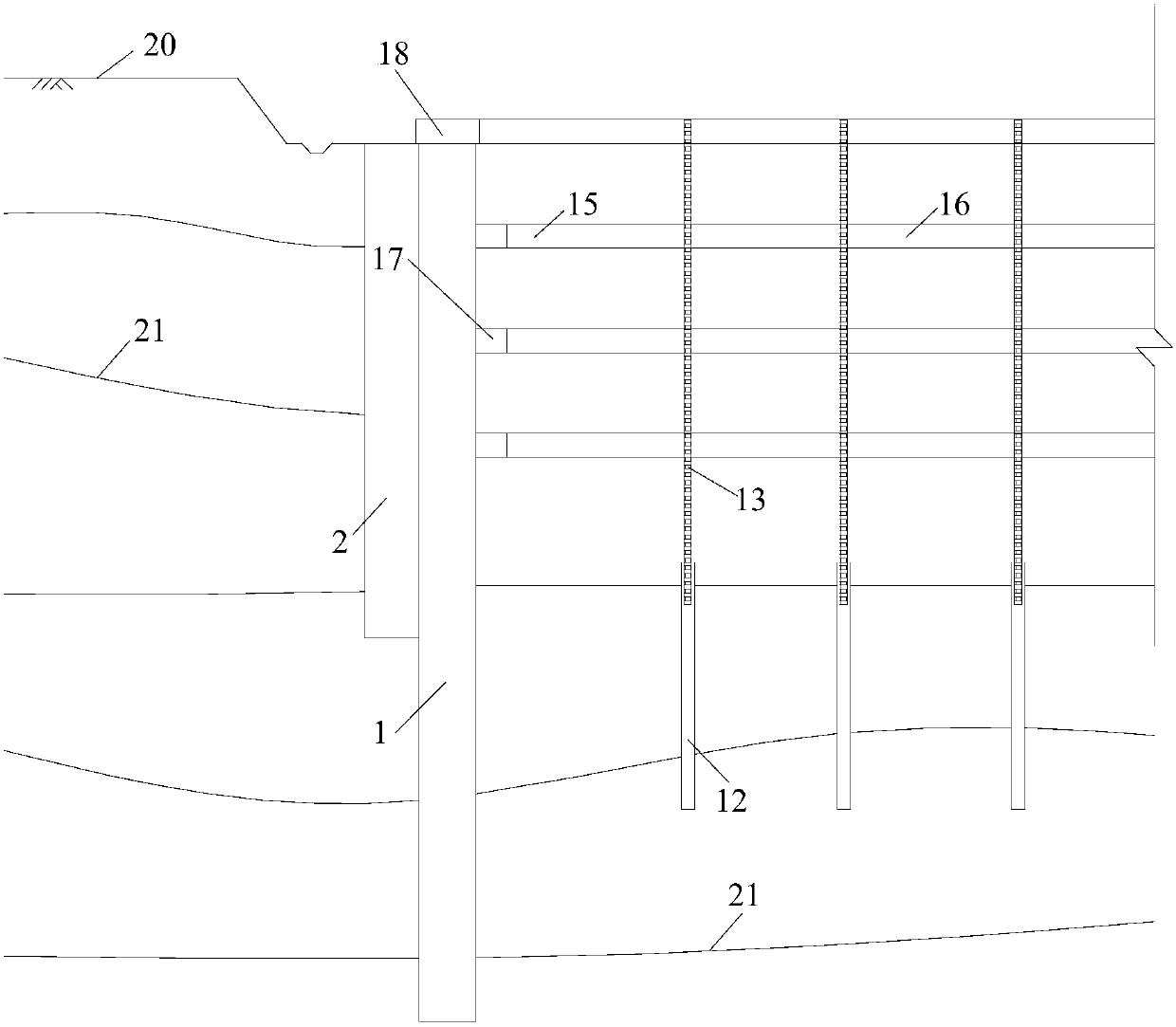

[0036] figure 1 It is a schematic diagram of the ultra-deep foundation pit supporting non-intermittent compound conversion structure, figure 2 It is a three-dimensional schematic diagram of the strong joint structure of the composite support transfer structure, Figure 3 to Figure 10 It is the construction process diagram of ultra-deep foundation pit support without intermittent compound conversion, refer to Figure 1-10 As shown, the construction process mainly includes foundation pit excavation and support structure construction, pit bottom treatment, floor pouring, floor support replacement construction, internal support removal, weak surface support setting, strong joint support and underground main structure construction, etc.

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com