Transfer plate

A technology for transfer plates and substrates, applied in printing, copying/marking methods, instruments, etc., can solve problems such as waste of PI liquid, and achieve the effect of ensuring quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

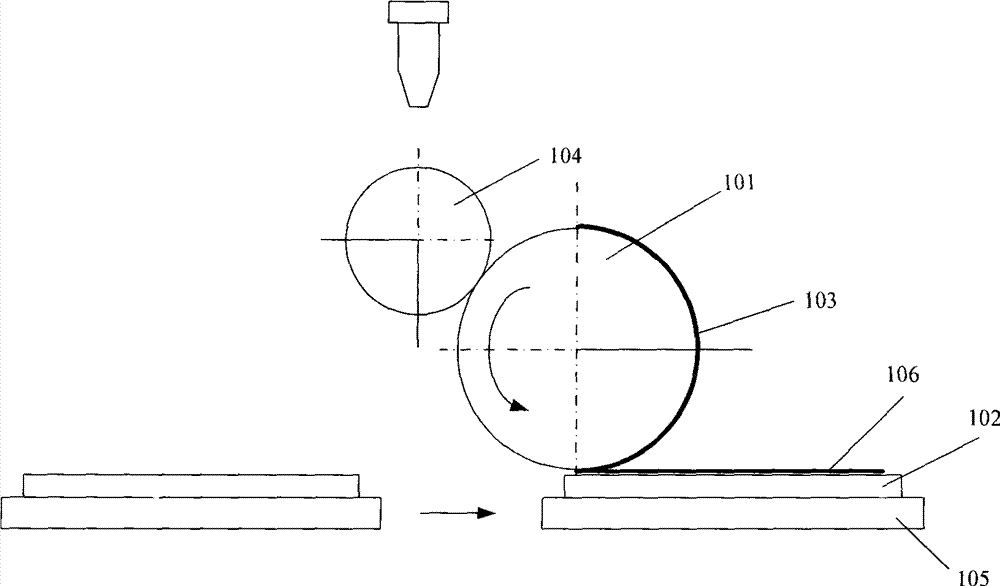

Method used

Image

Examples

Embodiment Construction

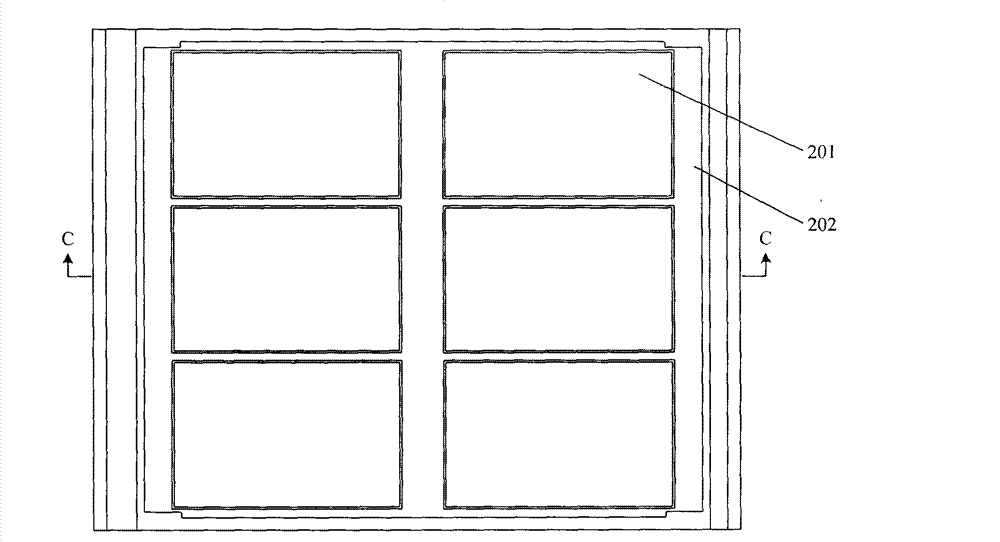

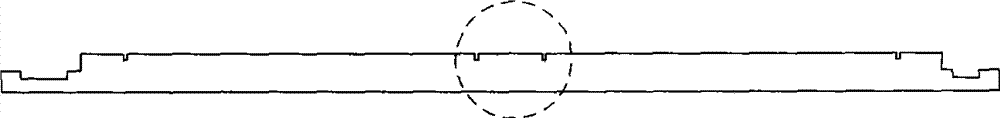

[0025] Such as Figure 3A Shown is the top view of the specific embodiment 1 of the transfer plate of the present invention. This embodiment is a PI transfer plate applied to printing PI liquid on the glass substrate of a thin film liquid crystal tube liquid crystal display. The transfer plate includes a substrate 1, the substrate Several display panel blocks 2 are arranged on 1, and a dummy block 3 is formed between several display panel blocks 2, wherein a blank block 4 is set in the dummy block 3 perpendicular to the printing direction A of the substrate 1, Such as Figure 3B shown as Figure 3A The C-C cross-section diagram, Figure 3C for Figure 3B A partial enlarged view of Figure 3B It can be seen that the upper surface of the blank block 4 is lower than the upper surface of the dummy block 3, further, the depth of the blank block 4 can be the same as the depth of the blank block at the edge of the printing area of the substrate 1 of the transfer plate same.

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| radius | aaaaa | aaaaa |

| radius | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com