Pre-bending device

A pre-bending and driving device technology, applied in the field of pre-bending devices, can solve the problems of inability to meet production requirements and straightening

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention will be further described below in conjunction with the accompanying drawings.

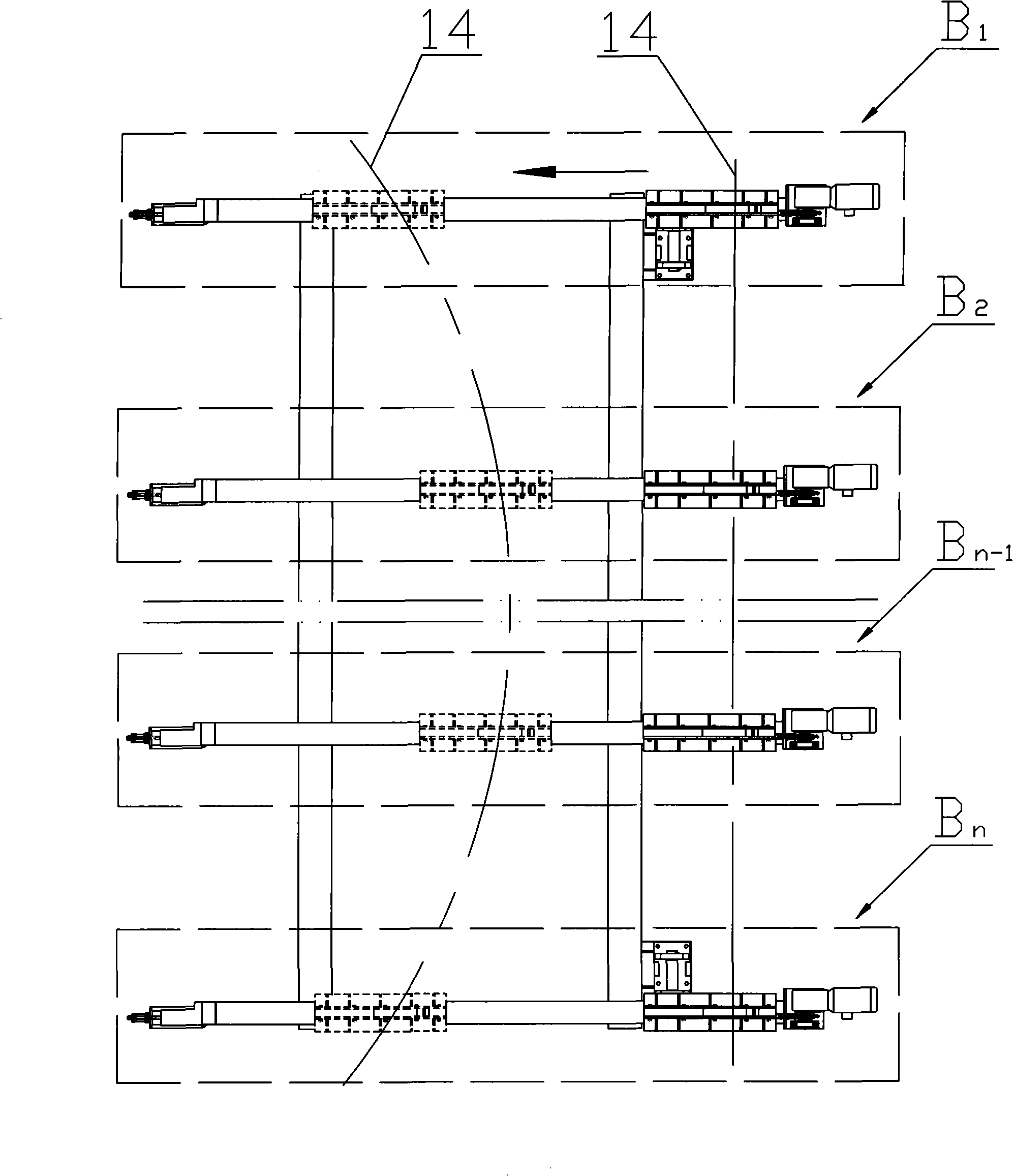

[0013] figure 1 As shown, the described pre-bending device consists of several pre-bending trolleys B arranged side by side 1 ~B n Composition, the number of pre-bending trolleys B can be determined according to the length of the produced special-shaped steel to ensure the amount of pre-bending in the opposite direction of the special-shaped steel.

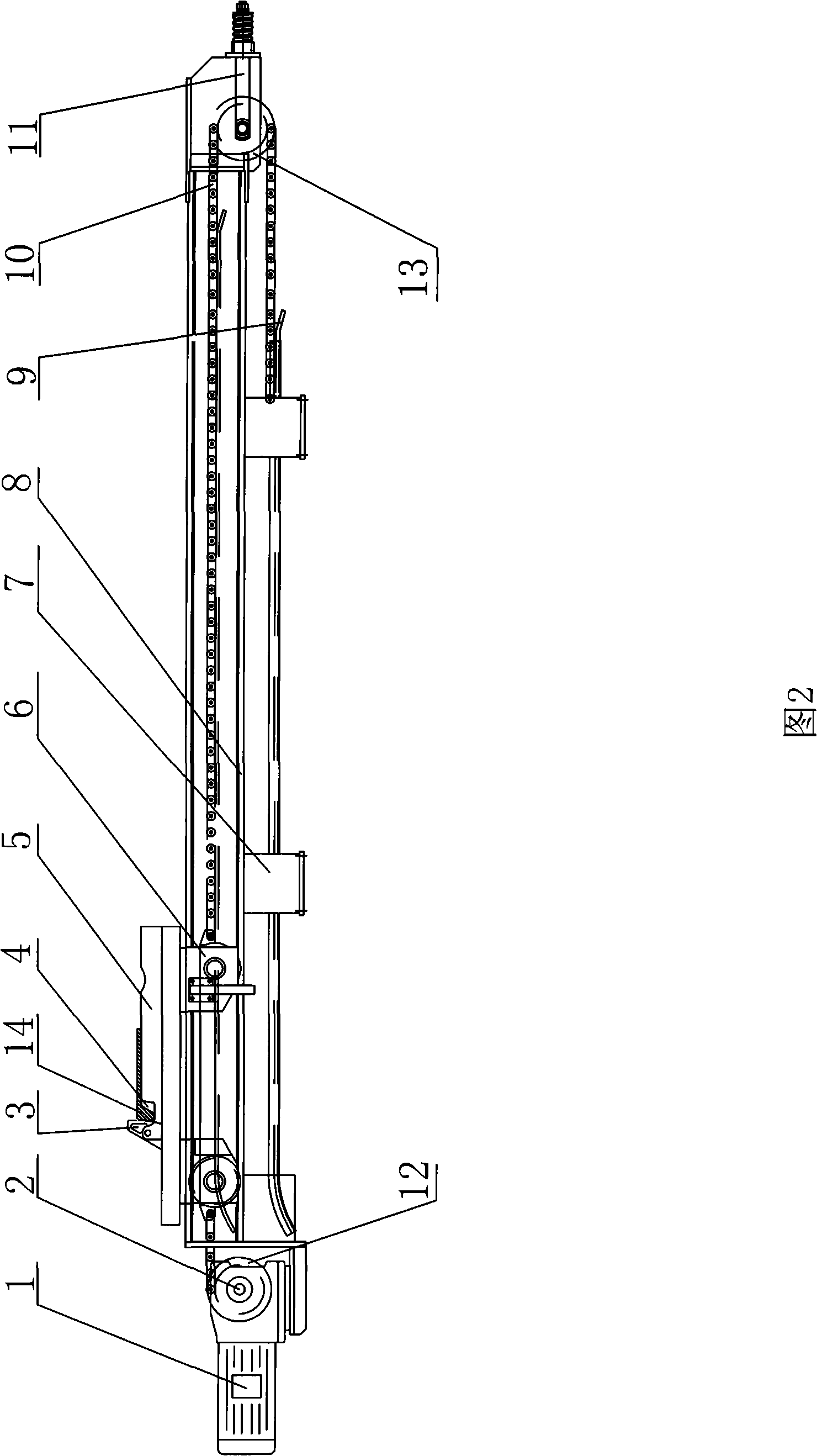

[0014] As shown in Figure 2, the structure of each pre-bending trolley B is as follows: on the support 7 of the pre-bending trolley B, a driving device 1 and a trolley guide rail 8 are arranged, and the output shaft of the driving device 1 is provided with a drive sprocket 12, and the trolley guide rail 8 is provided with a mobile trolley 6, one end of the chain 10 is fixed on the mobile trolley 6, and the other end is fixed on the mobile trolley after bypassing the driven sprocket 13 arranged on the bracket and the driv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com