A method for metallizing the surface of a ceramic substrate

A technology of ceramic substrate and surface metal, applied in metal material coating process, superimposed layer plating, coating and other directions, can solve the problems of insufficiency, long production cycle, high defect rate, and improve the final yield and return. The effect of simplifying the plating process and simplifying the production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

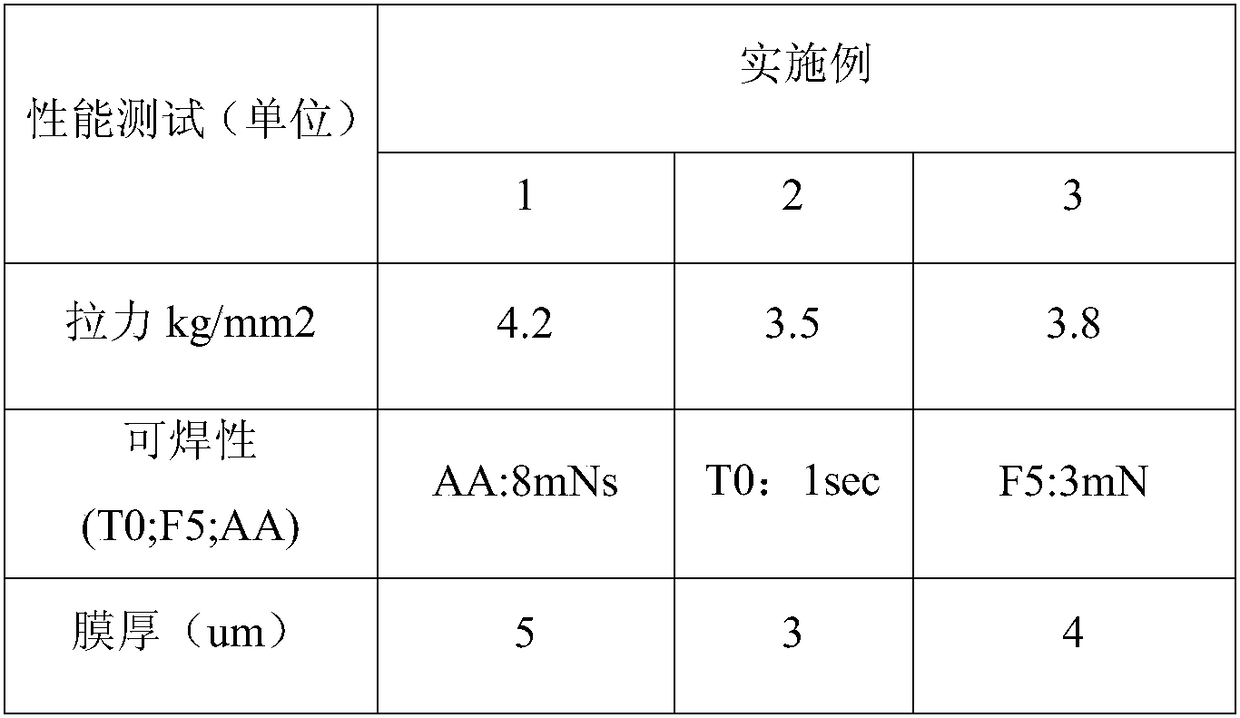

Examples

Embodiment 1

[0048] S1. Titanium-tungsten-copper plating: Titanium-tungsten and copper plating are performed on the surface of the ceramic substrate (first titanium-tungsten plating, then copper plating), the processing conditions are: vacuum degree 1×10 -8 , substrate temperature 150-200°C, argon pressure 4×10 -3 torr, bias -200V, time 30min, film thickness: titanium tungsten 0.05-0.1um, copper 0.5-1um;

[0049] S2. Degreasing: put the substrate obtained in S1 into the degreasing solution at a temperature of 30°C, take it out after degreasing for 10 minutes, and rinse it with deionized water for 4 times; wherein, each 1L of degreasing agent contains 100ml of acidic degreasing agent FR, 200ml of sulfuric acid, and the rest is water ;

[0050] S3, acidification corrosion: put the substrate obtained in S2 into the corrosion solution, after acidification corrosion at room temperature for 30s, rinse with deionized water twice; wherein, each 1L corrosion solution contains 200g of sodium persul...

Embodiment 2

[0065] S1. Titanium-tungsten-copper plating: Titanium-tungsten and copper plating are performed on the surface of the ceramic substrate (first titanium-tungsten plating, then copper plating), the processing conditions are: vacuum degree 1×10 -8 , substrate temperature 150-200°C, argon pressure 4×10 -3 torr, bias -200V, time 30min, film thickness: titanium tungsten 0.05-0.1um, copper 0.5-1um;

[0066] S2. Degreasing: put the substrate obtained in S1 into the degreasing solution at a temperature of 25°C, take it out after degreasing for 5 minutes, and rinse it with deionized water for 6 times; wherein, each 1L of degreasing agent contains 80ml of acidic degreasing agent FR, 150ml of sulfuric acid, and the rest is water ;

[0067] S3, acidification corrosion: put the substrate obtained in S2 into the corrosion solution, after acidification corrosion at room temperature for 20s, rinse with deionized water for 3 times; wherein, each 1L corrosion solution contains 150g of sodium pe...

Embodiment 3

[0082] S1. Titanium-tungsten-copper plating: Titanium-tungsten and copper plating are performed on the surface of the ceramic substrate (first titanium-tungsten plating, then copper plating), the processing conditions are: vacuum degree 1×10 -8 , substrate temperature 150-200°C, argon pressure 4×10 -3 torr, bias -200V, time 30min, film thickness: titanium tungsten 0.05-0.1um, copper 0.5-1um;

[0083] S2. Degreasing: put the substrate obtained in S1 into the degreasing solution at a temperature of 35°C, take it out after degreasing for 10 minutes, and rinse it with deionized water for 5 times; wherein, each 1L of degreasing agent contains 120ml of acidic degreasing agent FR, 250ml of sulfuric acid, and the rest is water ;

[0084] S3. Acidification corrosion: put the substrate obtained in S2 into the corrosion solution, and after acidification corrosion at room temperature for 40 seconds, wash it with deionized water for 3 times; wherein, each 1L corrosion solution contains 25...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com