Silica-gel push-button and forming method thereof

A molding method and key technology, applied in electrical components, electrical switches, circuits, etc., can solve the problems of complex production process, high labor and material costs, etc., and achieve the effect of simple process, reduction of labor and material costs, and quality assurance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

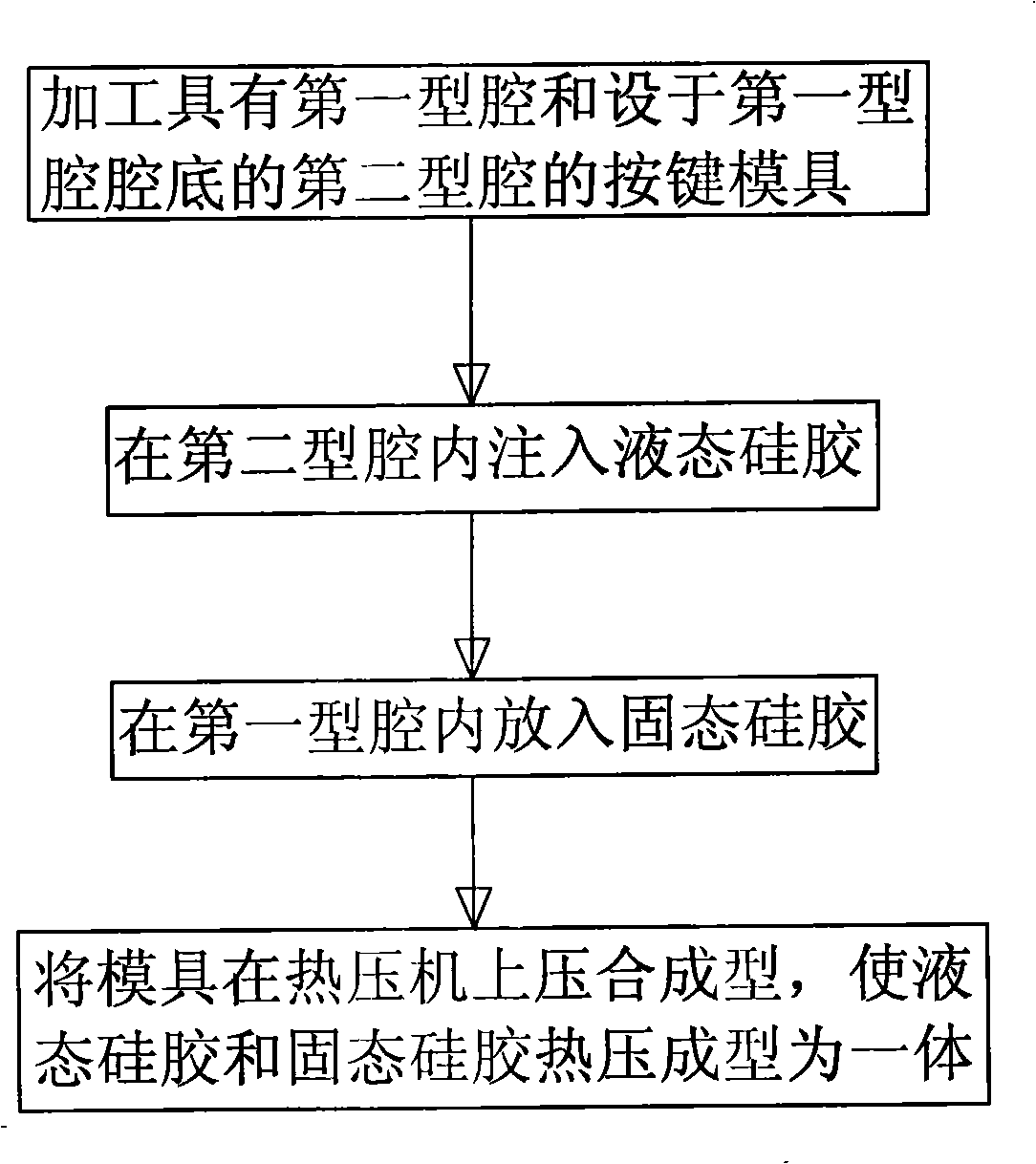

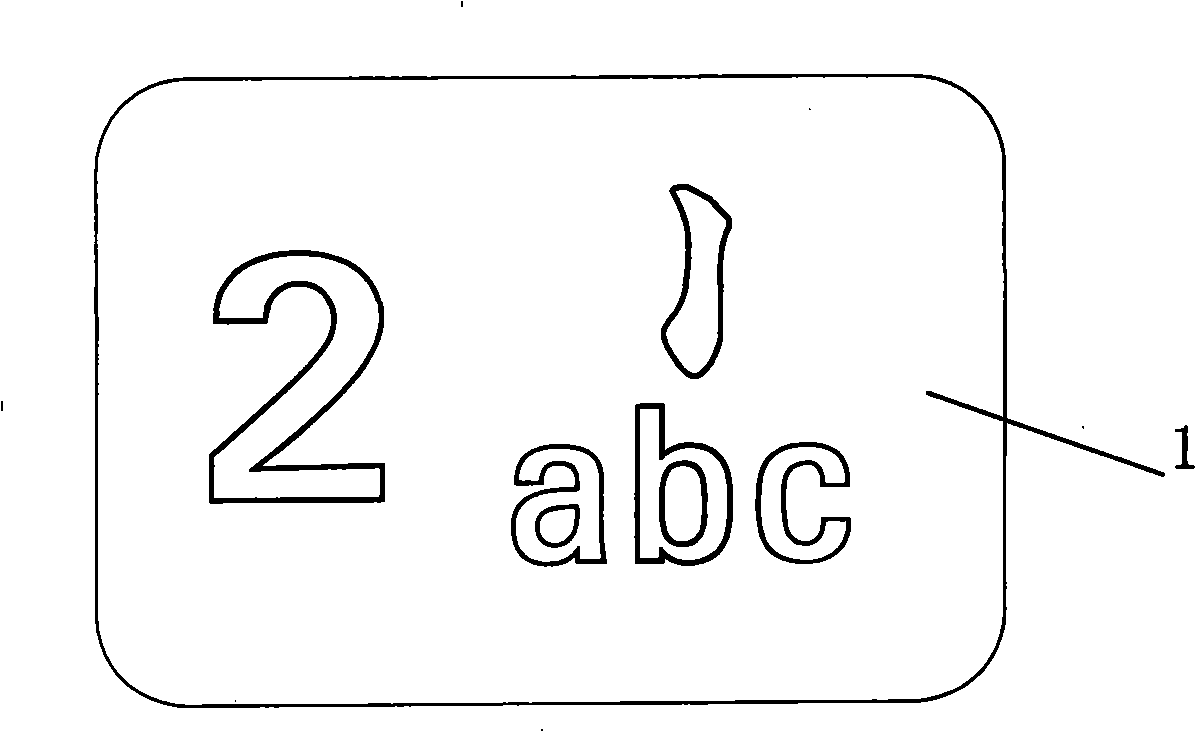

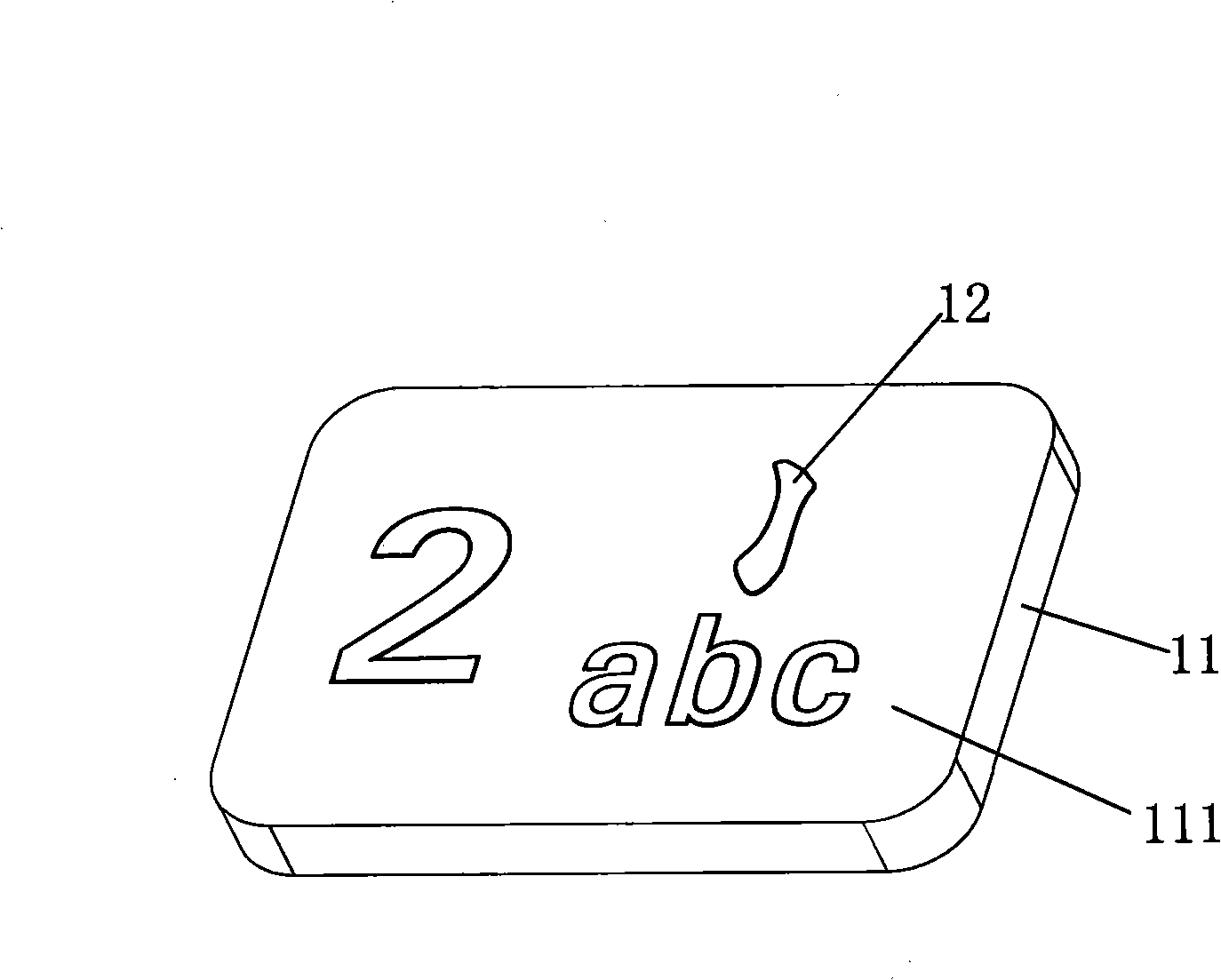

[0026] Such as Figure 1 to Figure 3 As shown, a molding method of a silicone button in this embodiment is used for molding a silicone button. The silicone button 1 is composed of a button base 11 and at least one button character 12 disposed on the surface 111 of the button base. The molding method includes the following steps: a) process button mould, this button mold has the first mold cavity of molding button substrate and the second mold cavity of the molding button character that is located at the bottom of this first mold cavity cavity, the quantity of this second mold cavity and each silica gel button The number of key characters is consistent, and each cavity is formed by electrode discharge, and sandblasting is performed to prevent the formed silicone key from sticking to the mold when it is demoulded; b) inject liquid silicone into each second cavity of the mold, The color of the liquid silicone is selected according to the color of the key characters, and the liqui...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap