Assembly device with an assembly control system

A technology for controlling systems and assembling devices, applied in measuring devices, special recording/indicating devices, and transmitting sensing components using wave/particle radiation devices, etc., and can solve problems such as device damage, rupture, and poor installation conditions.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

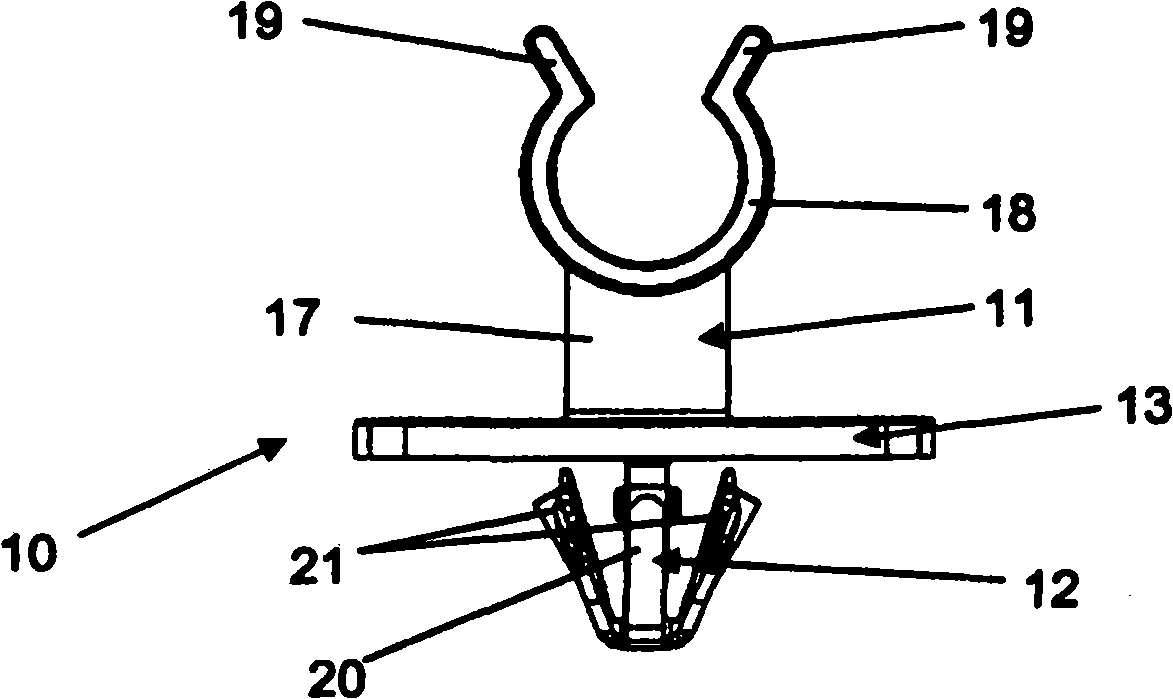

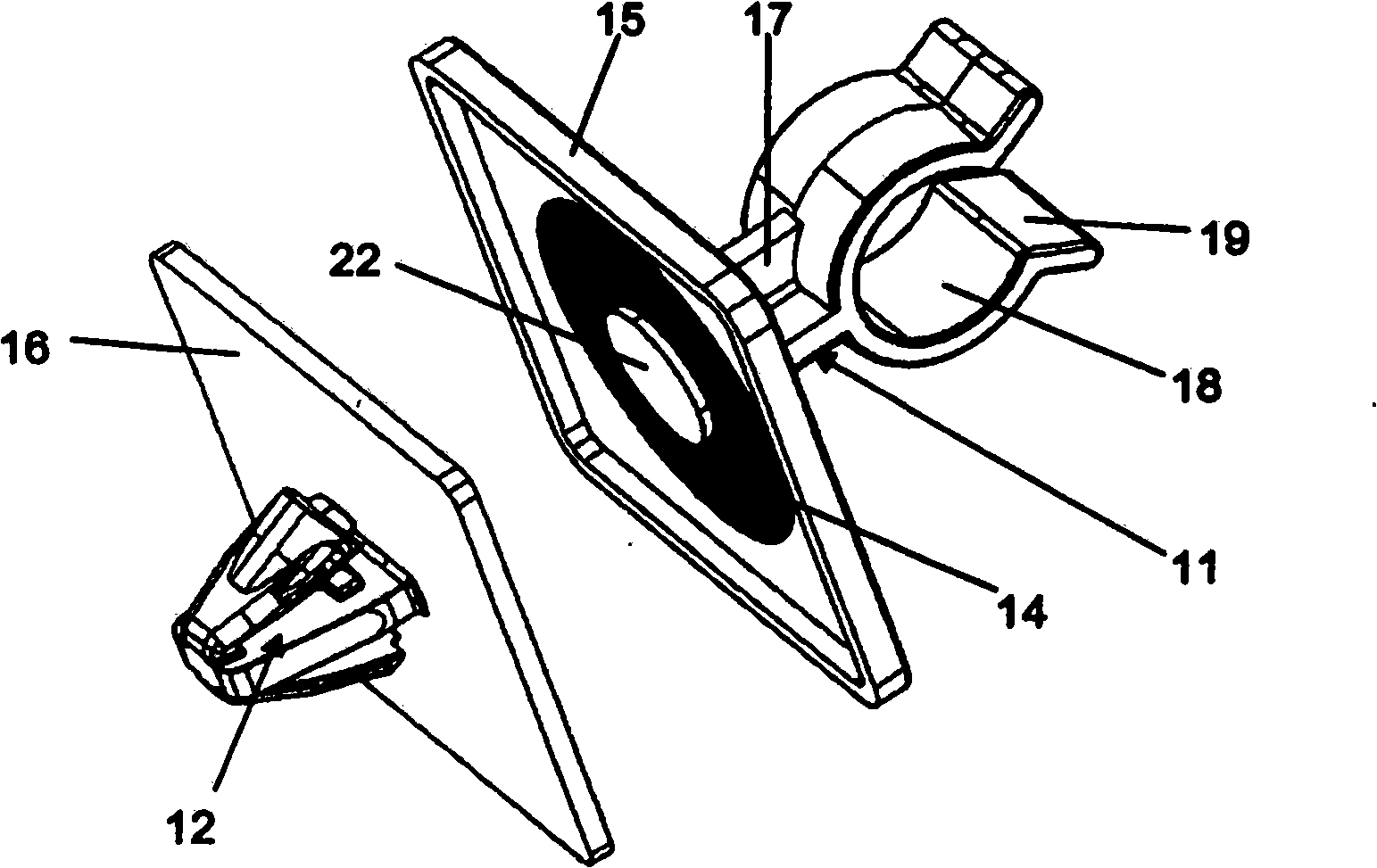

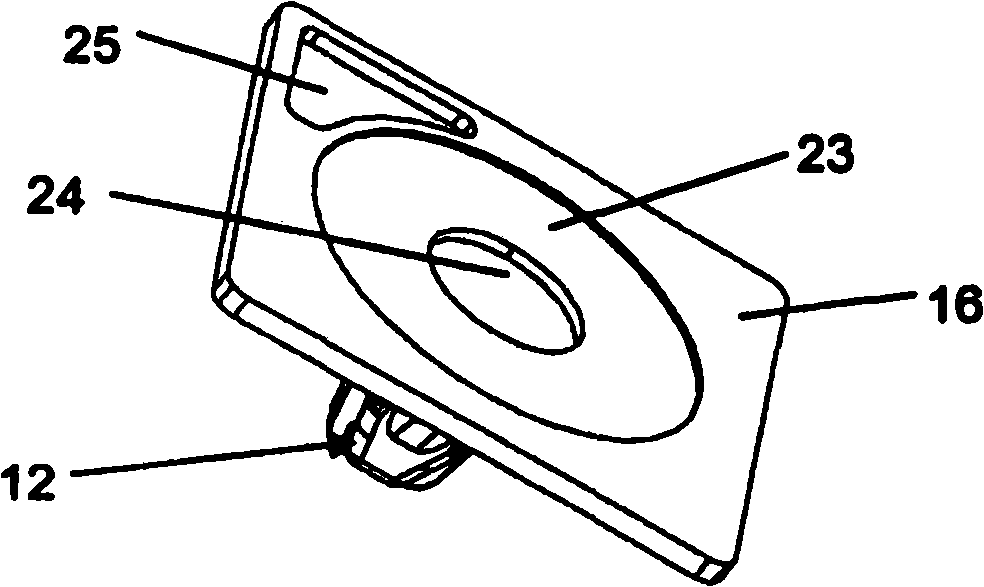

[0016] Figure 1 to Figure 3 A first embodiment of the assembly device according to the invention is shown. The assembly device referenced 10 is elongate and is designed for assembling the tube to a frame (neither shown), the assembly device having an upper part 11 matching the tube and for attaching the assembly device 10 Fixed to the lower part 12 on the bracket. In the variant shown, the upper part 11 and the lower part 12 consist of two one-piece plastic components which are integrated into one another in the central region of the assembly device 10 .

[0017] The central area of the assembly device 10 forms a rectangular box 13 with a small thickness designed to accommodate a ring-shaped radio frequency tag 14 . The box 13 is composed of a rectangular cover 15 belonging to the upper part 11 and a plate 16 belonging to the lower part 12 and complementary in shape to said cover 15 .

[0018] Extending from the outer surface of the cap 15 is a retainer 17 for a circlip ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com