Silicon steel double-roller type coating machine frame swaying method and device

A swing device, coating machine technology, applied to the surface coating liquid device, coating, etc., can solve the problems of increasing spare parts turnover, production cost, lack of interchangeability, etc., to achieve reduced turnover of spare parts, uniform Thickness of the top and bottom surfaces and the effect of simplifying spare parts management

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

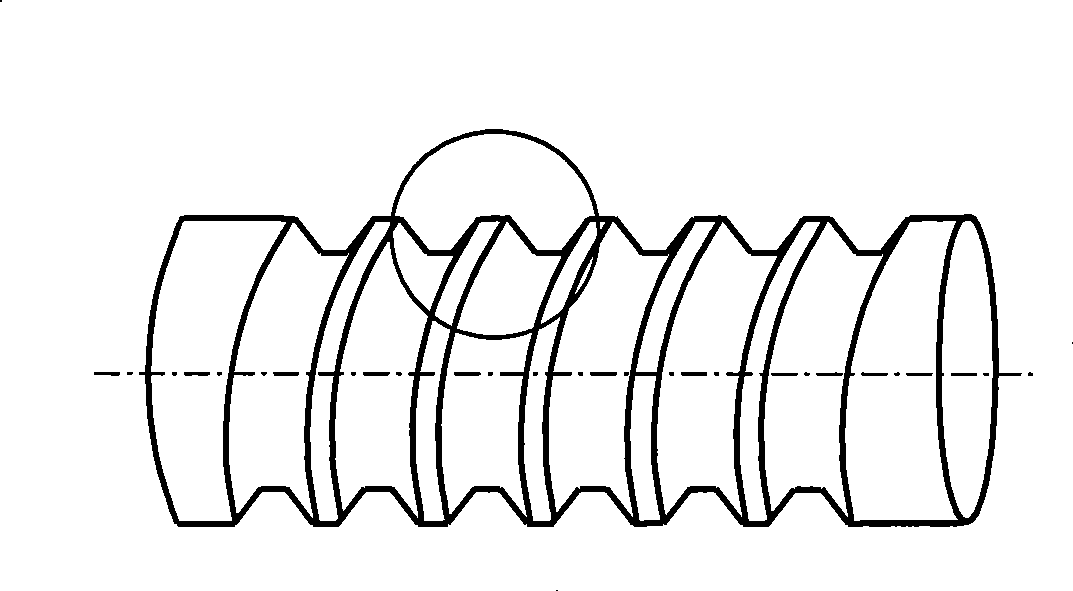

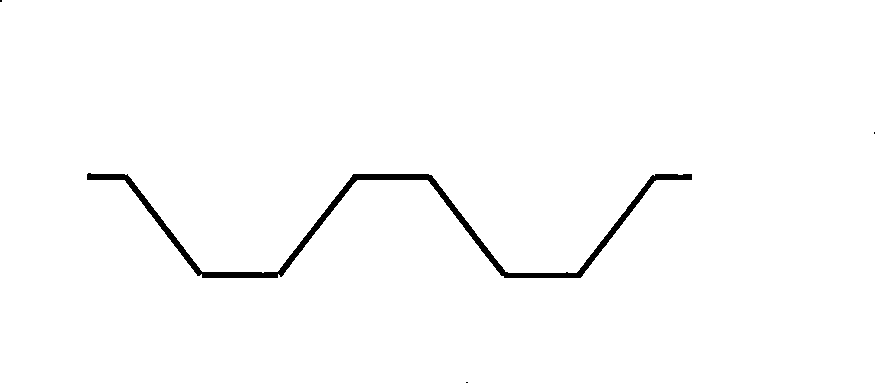

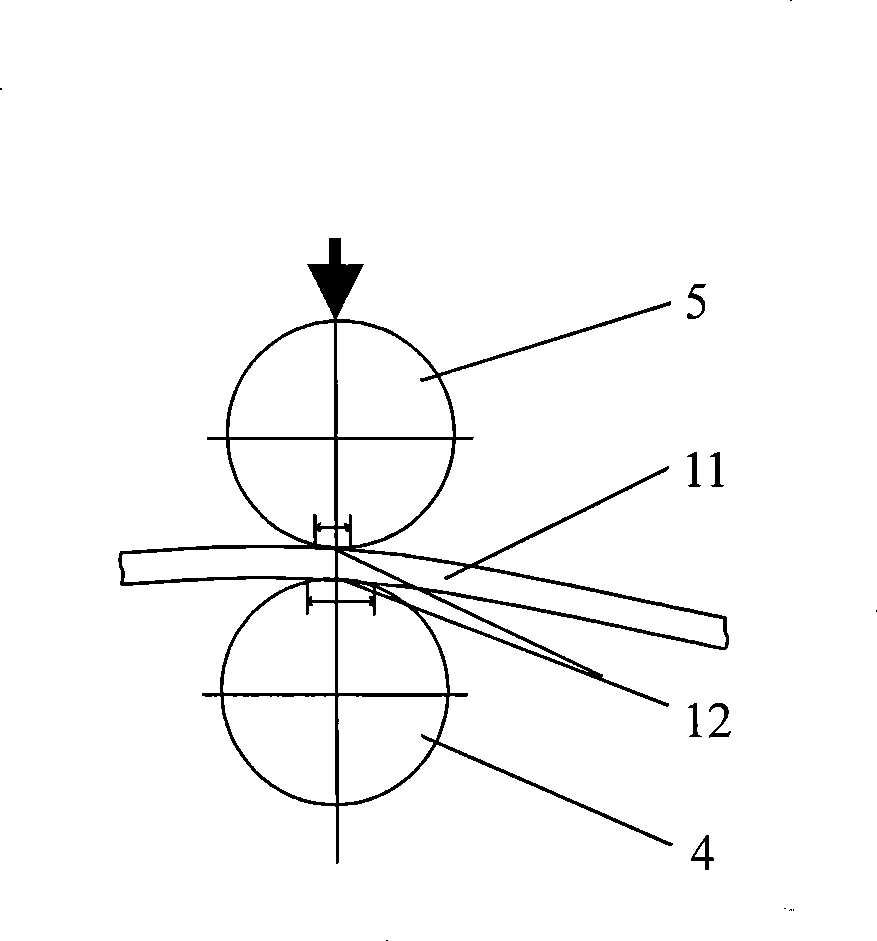

[0019] see Figure 4 , a method for swinging the frame of a silicon steel two-roller coating machine. When the thickness of the upper and lower coatings is inconsistent due to changes in the 11-channel line of the strip steel, the overall coating machine is swung to an appropriate position, just to make the coating machine The axis of the coating machine is perpendicular to the outlet strip 11, the axis of the coating machine refers to the connecting line of the shaft centers of the upper and lower coating rollers 5, 4, and the angle A of the axis of the coating machine is 0 ~ 10 °, so that The contact area 12 between the steel strip 11 and the upper and lower coating rollers 5, 4 is consistent or basically consistent, so that the ability of the upper and lower coating rollers 5, 4 to maintain the coating solution is basically close, and finall...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com