Connecting structure between water chamber and main slices of novel vehicle radiator

A car radiator and connection structure technology, which is applied to radiators, heat exchanger types, heat exchanger shells, etc., can solve problems such as leakage and scrapping, poor sealing, and weak welding between the water chamber and the main sheet

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

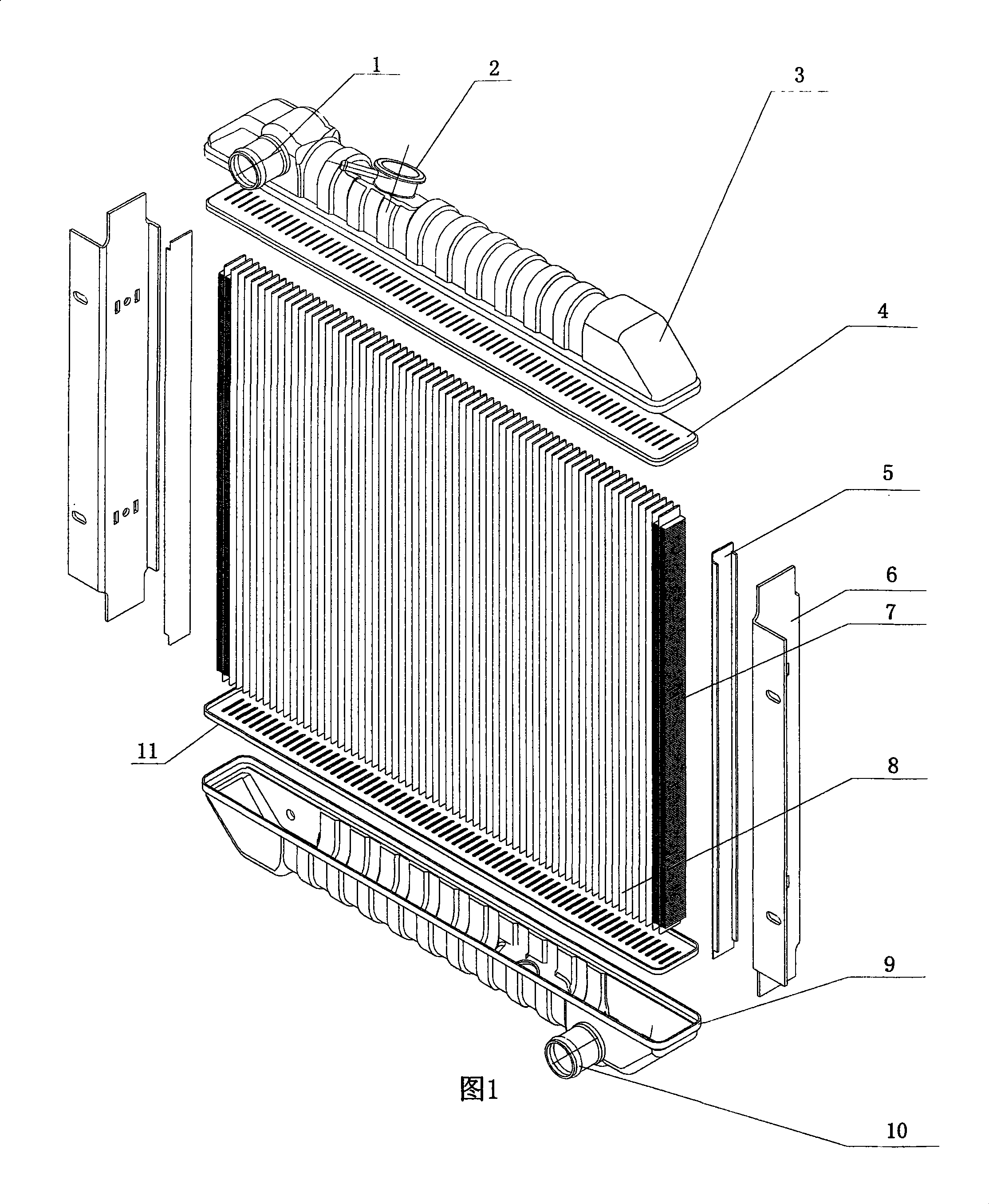

[0014] Referring to Fig. 1, the automobile radiator that the present invention relates to mainly consists of a water inlet pipe 1, a water inlet 2, an upper water chamber 3, an upper main sheet 4, a side plate 5, an installation side plate 6, a fin 7, a flat pipe 8, a water inlet Chamber 9, water outlet 10 and lower main sheet 11 form.

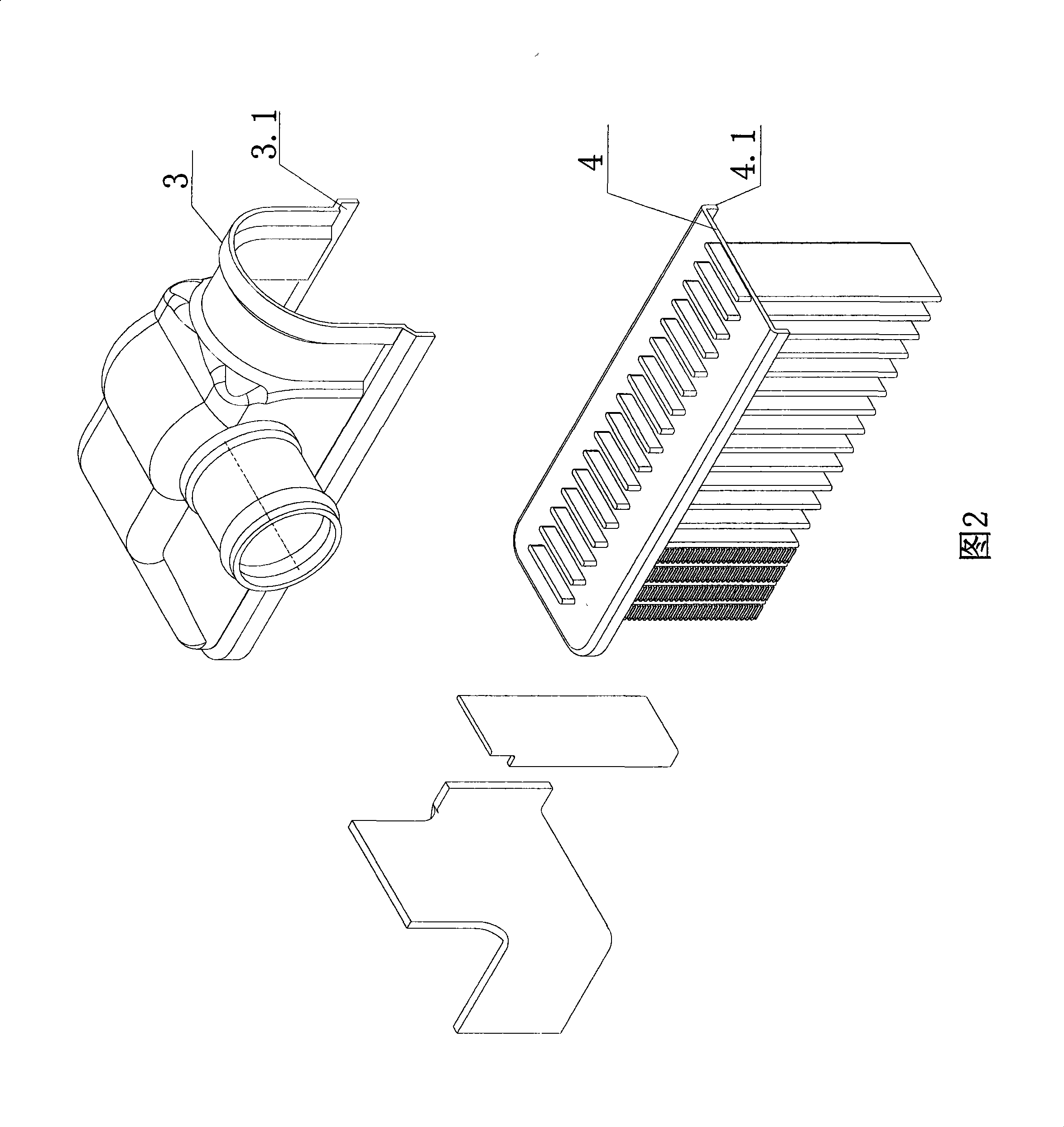

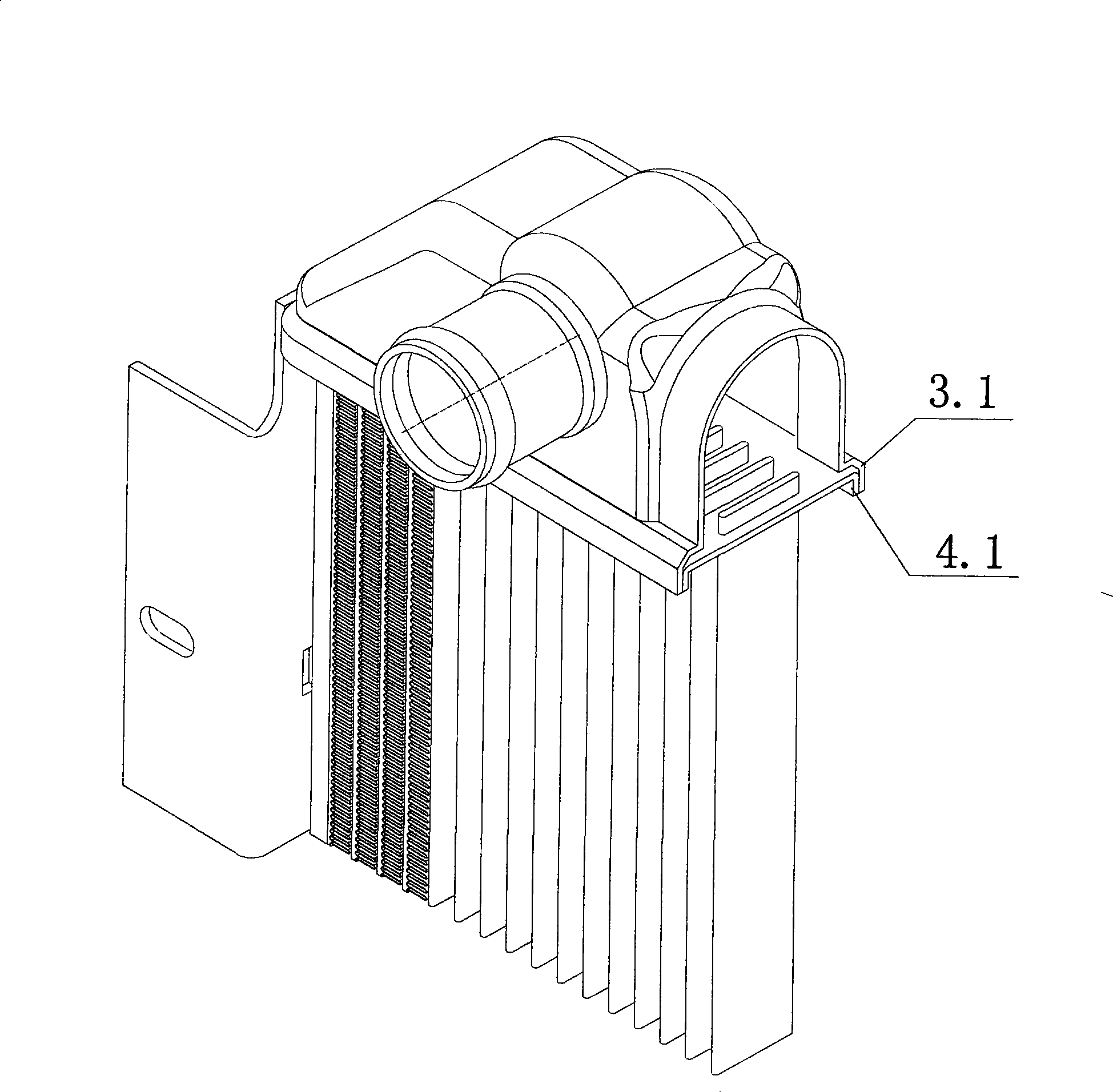

[0015] Referring to Fig. 2, the lower edge of the upper water chamber 3 is expanded outwards with a circle of outer wrapping edge I 3.1, corresponding to the circle of outer wrapping edge I 3.1, the outer edge of the upper main piece 4 is vertically provided with a circle of inner wrapping edge downwards I4.1, the outer wrapping edge I 3.1 of the lower edge of the upper water chamber 3 is tightly wrapped around the inner wrapping edge I 4.1 of the outer edge of the upper main piece 4, and is fixed by brazing. Such as image 3 .

[0016] see Figure 4 , the upper edge of the lower water chamber 9 extends outwards with a circle of outer edge I...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com