Oil sump for horizontal diesel engine

A technology for oil pans and diesel engines, which is applied to mechanical equipment, engine components, machines/engines, etc. It can solve problems such as difficult to comment one by one, and achieve the effects of enhancing aesthetics, reducing noise emissions, and enhancing overall strength and rigidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

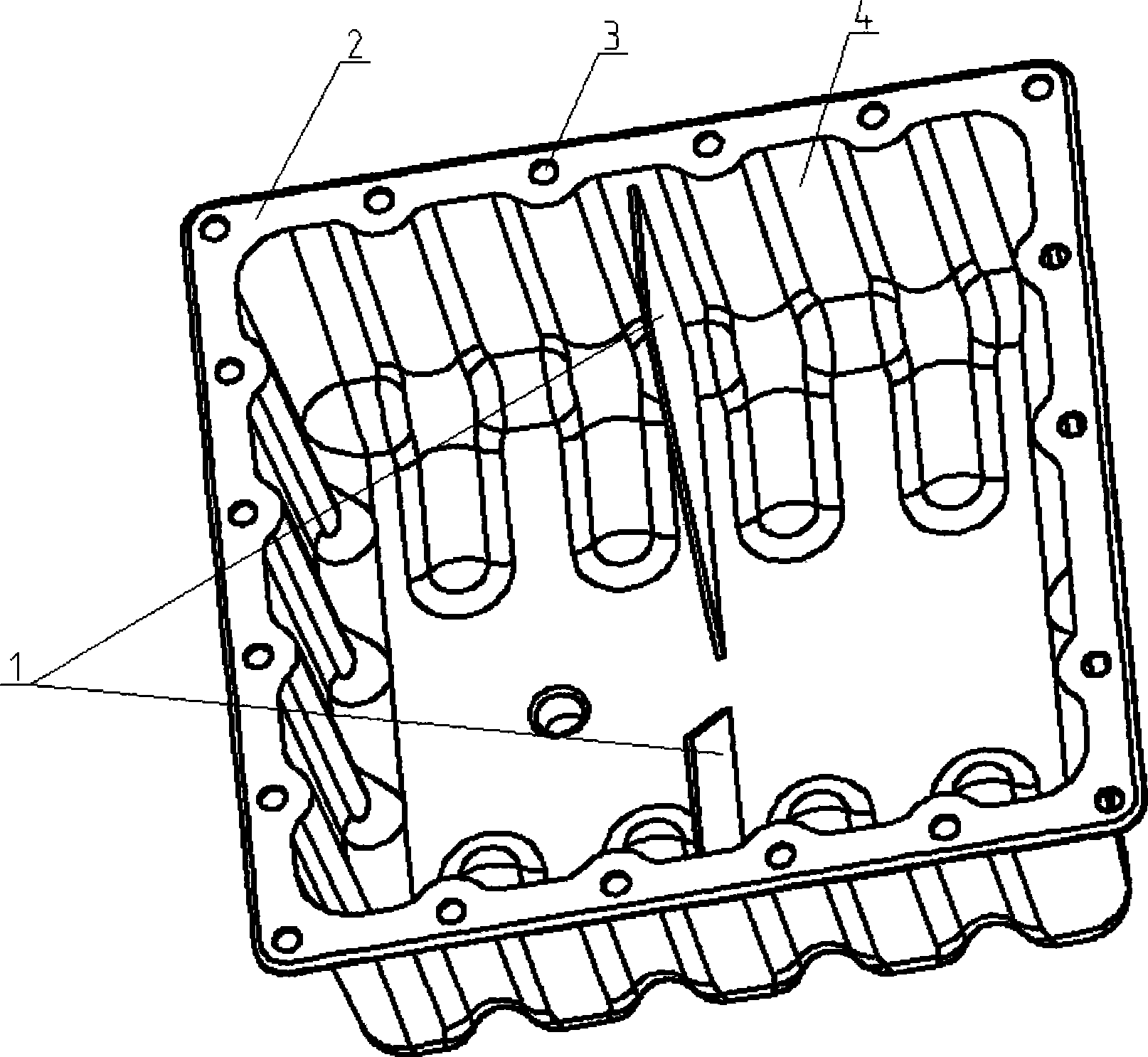

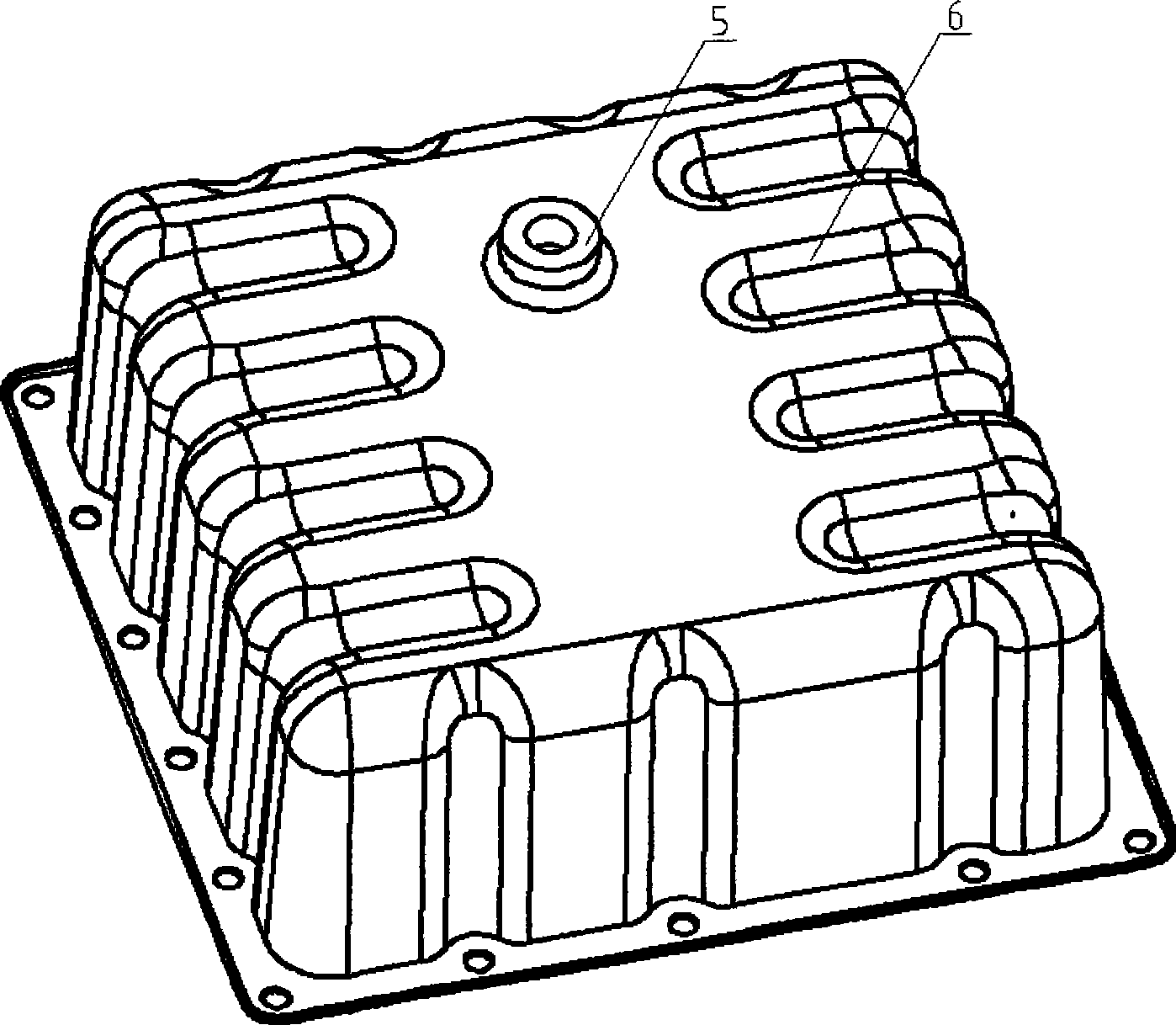

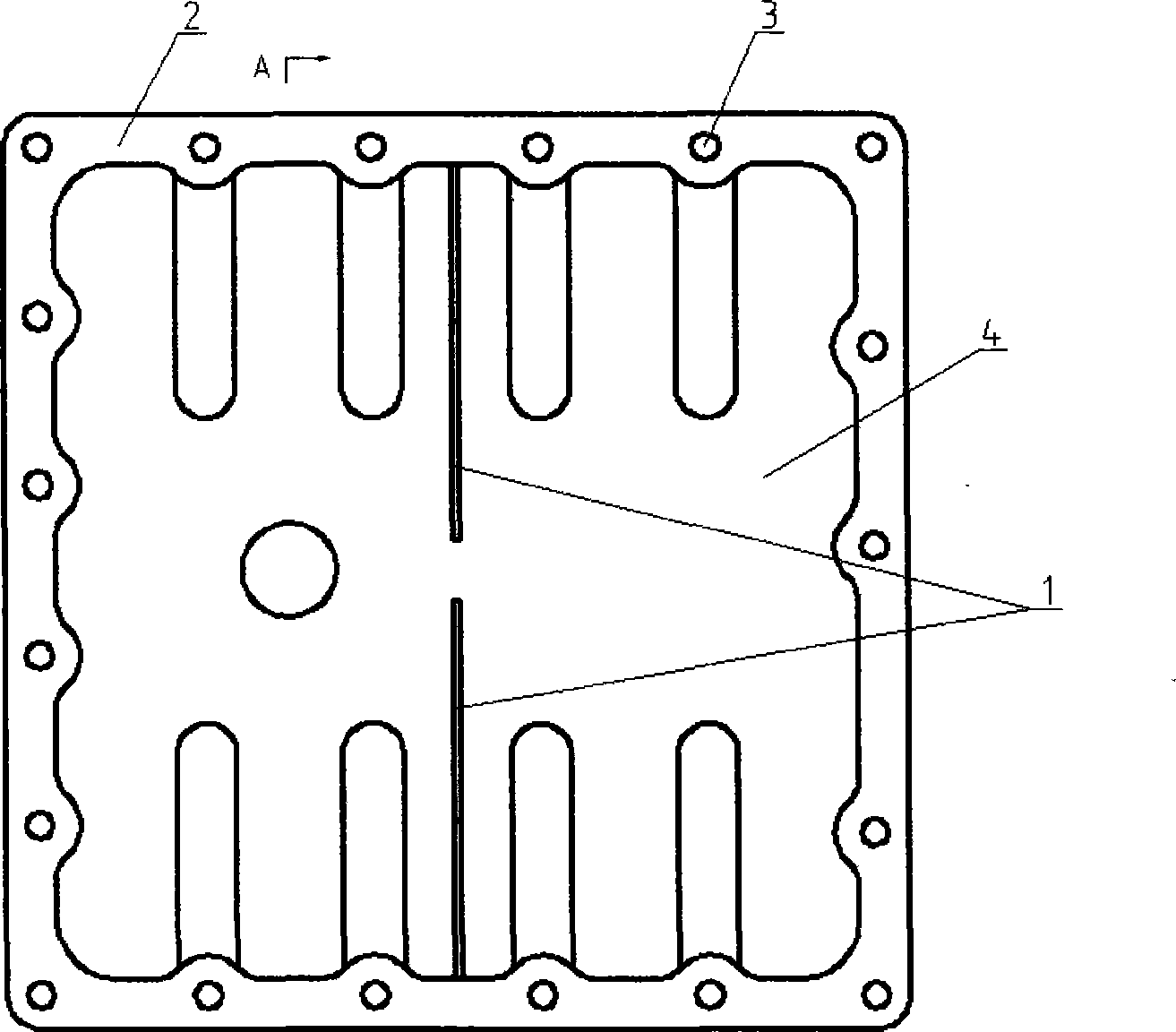

[0016] Embodiment 1: The oil pan of a horizontal double-cylinder diesel engine consists of an oil pan oil separator (1), an oil pan mounting surface (2), an oil pan mounting bolt hole (3), an inner cavity (4), and a The oil bolt seat (5) and the circular arc concave reinforcement rib (6) are composed of several oil pan oil separators (1) in the inner cavity (4) of the oil pan, and on each wall surface of the oil pan There are several smooth circular-arc concave reinforcing ribs (6), several oil pan mounting bolt holes (3) are provided on the oil pan mounting surface (2) on the upper part of the oil pan, and there are Oil drain bolt seat (5). The oil pan is used on twin-cylinder engines.

Embodiment 2

[0017] Embodiment 2: The oil pan of a horizontal single-cylinder diesel engine consists of an oil pan oil separator (1), an oil pan mounting surface (2), an oil pan mounting bolt hole (3), an inner cavity (4), and a The oil bolt seat (5) and the circular arc concave reinforcement rib (6) are composed of several oil pan oil separators (1) in the inner cavity (4) of the oil pan, and on each wall surface of the oil pan There are several smooth circular-arc concave reinforcing ribs (6), several oil pan mounting bolt holes (3) are provided on the oil pan mounting surface (2) on the upper part of the oil pan, and there are Oil drain bolt seat (5). The oil pan is used on single-cylinder engines.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com