Tube stand of backlight module

A technology for backlight modules and lamp tubes, applied in optics, light source fixation, nonlinear optics, etc., can solve problems such as inconvenient assembly of backlight modules, breaking force arms, and component damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

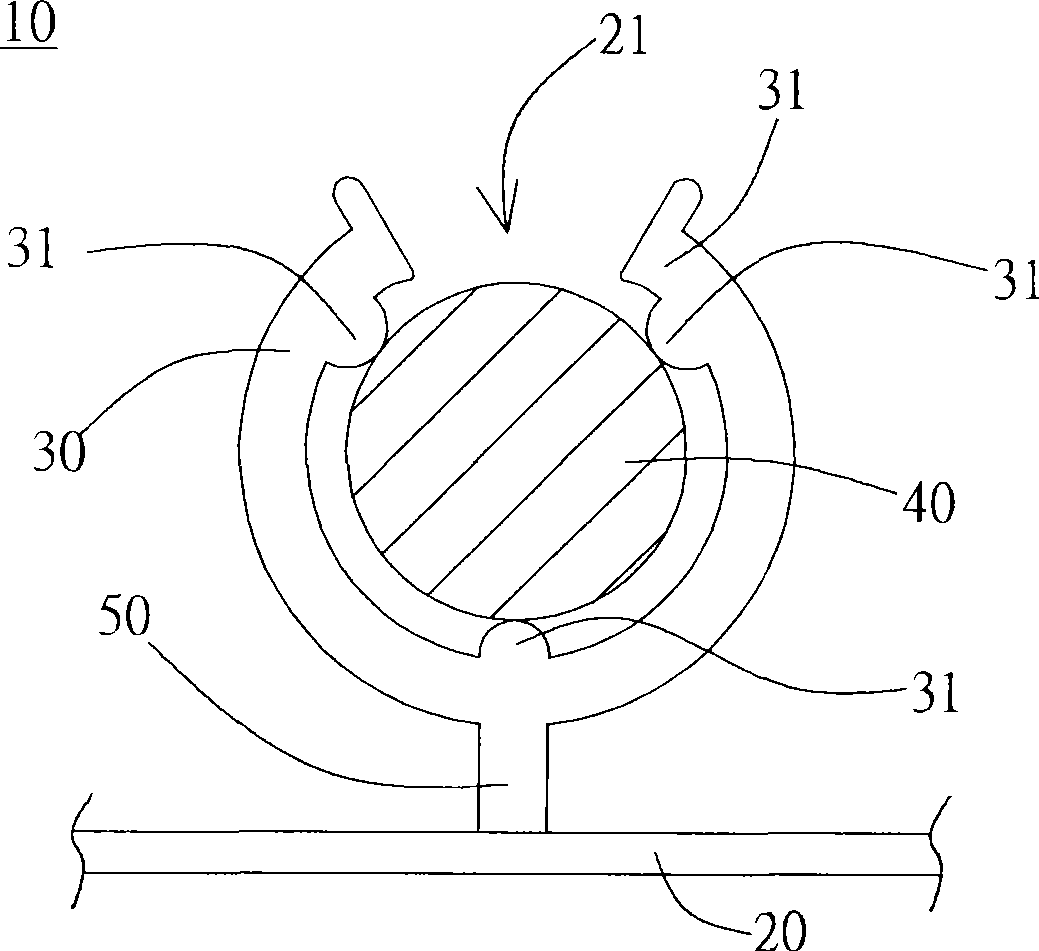

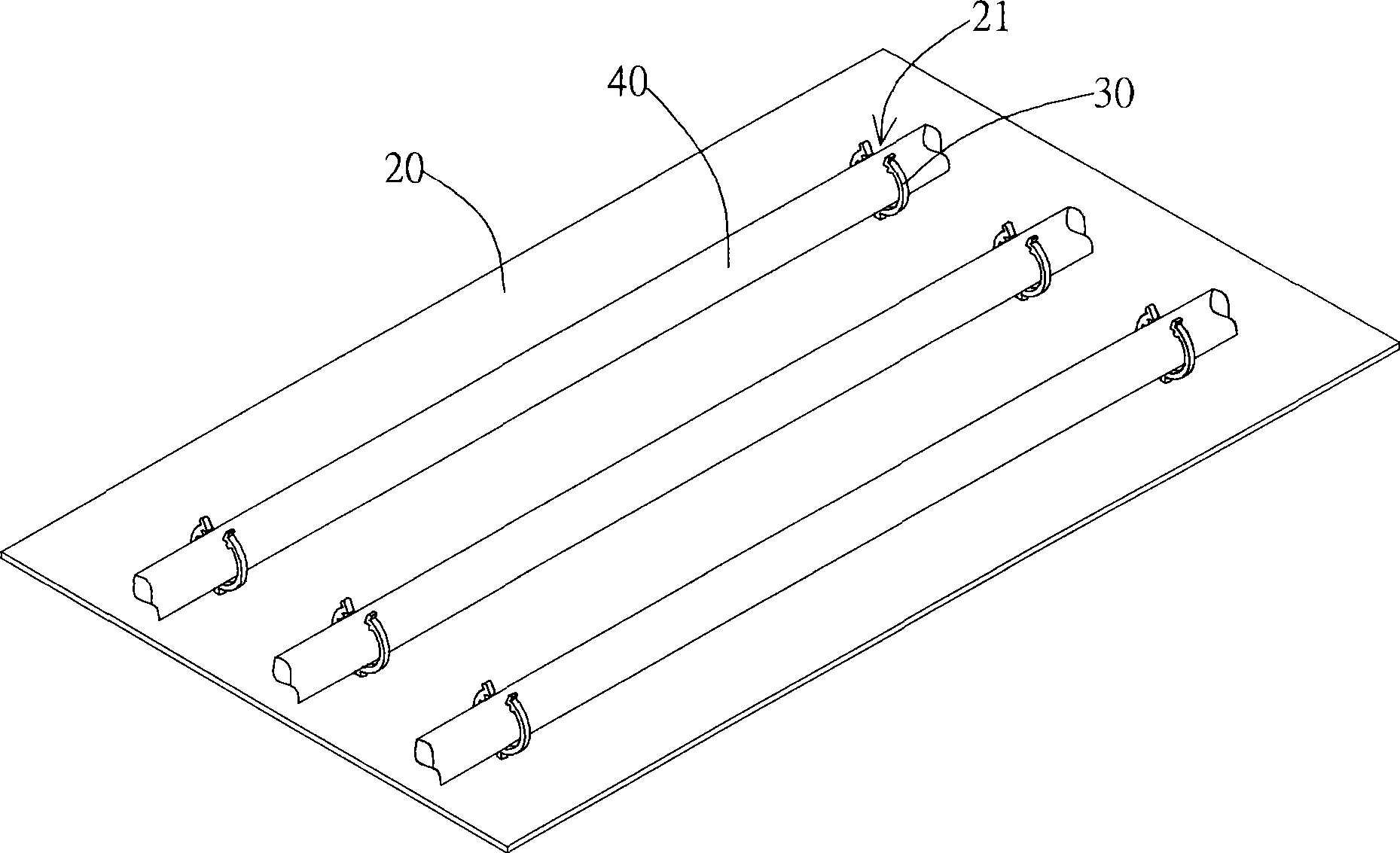

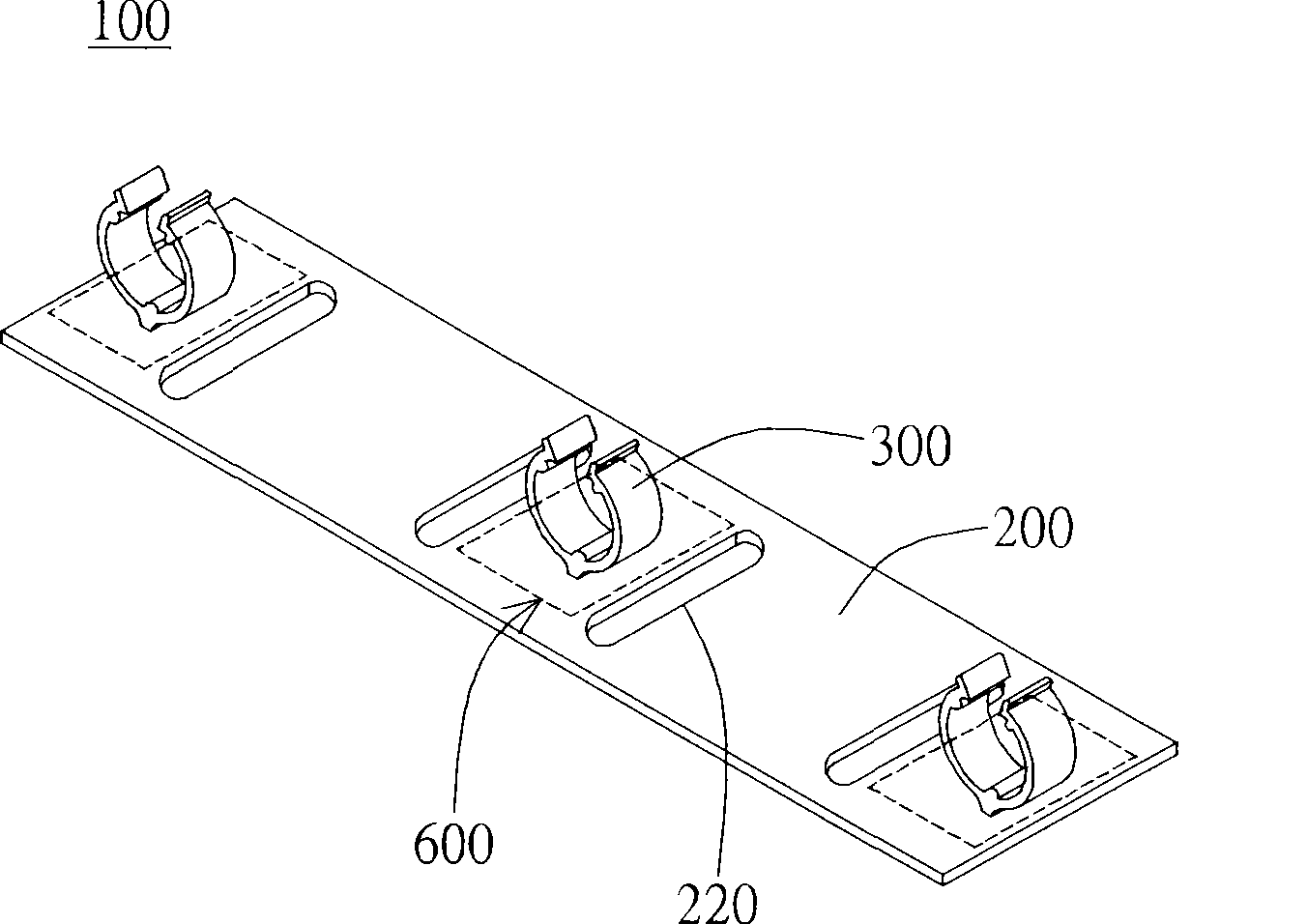

[0040] Such as Figure 2a In the illustrated embodiment, the backlight module lamp holder 100 of the present invention includes a base 200 and a lamp clamping portion 300, wherein the base 200 has a hollowed-out gap 220 and a connection area 600 (shown as a dotted line), wherein the hollowed-out gap 220 Adjacent to the connection area 600. The lamp holder 300 is disposed on the base 200 and in the connection area 600 of the base. Among them, the base 200 is made of a flexible material, such as polycarbonate (PC), acrylonitrilebutadiene styrene (ABS), polypropylene (PP), polyterephthalene Polyethylene terephthalate (PET), polymethylmethacrylate (PMMA), polylactic acid (PLA) or mixtures thereof. The lamp holder 300 is made of polymer, metal, metal alloy or metal compound. However, the flexible material of the aforementioned base 200 is not limited to this.

[0041] Such as Figure 2a In the preferred embodiment shown, the hollowed-out gap 220 on the base 200 is located on the side o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com