Method for making tridimensional designs

A production method and pattern technology, which are applied in the process, decorative art, ink and other directions for producing decorative surface effects, can solve the problems of high production cost, complex production process, complex mold structure, etc., and achieve short production time and simple process. , the effect of convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

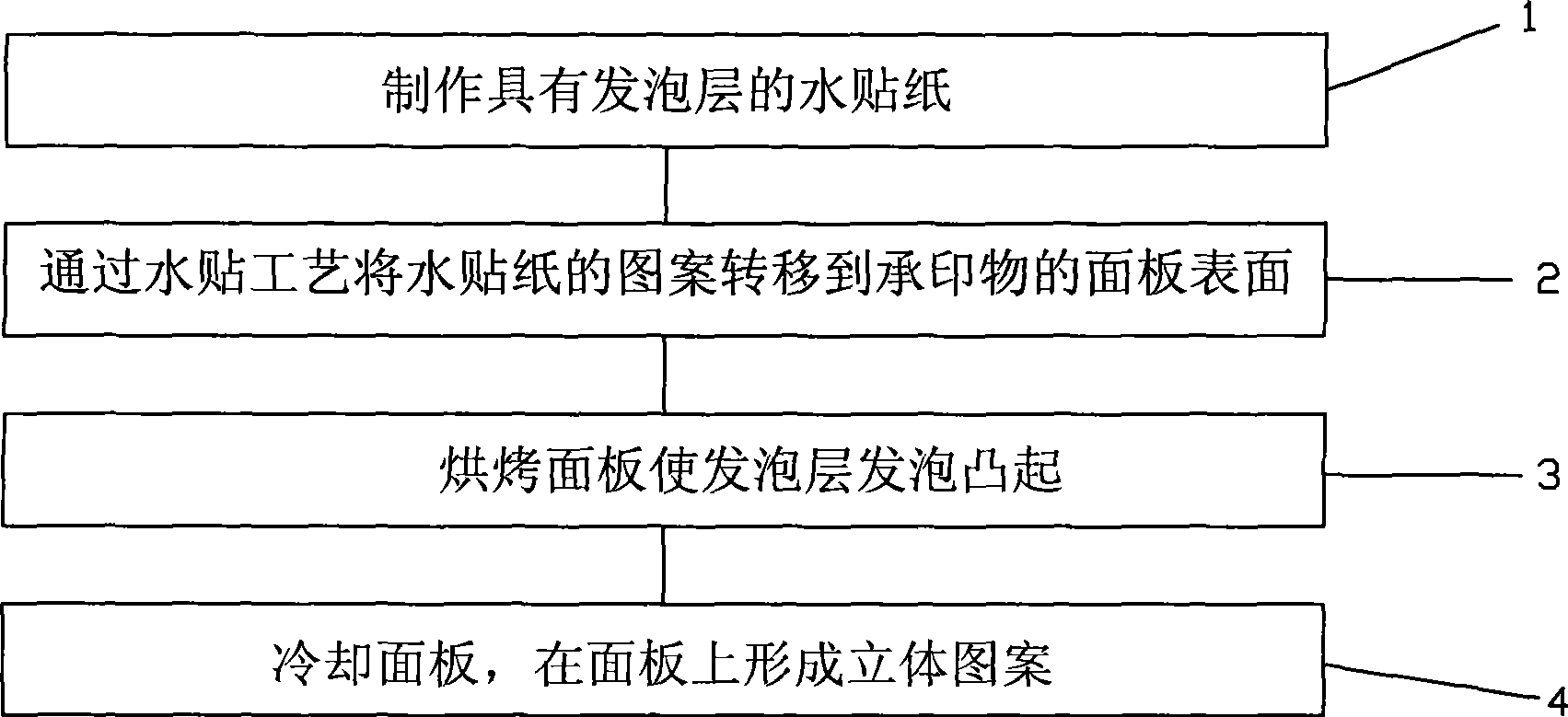

[0014] Such as figure 1 Shown, the preparation method of three-dimensional pattern of the present invention comprises:

[0015] Step 1: Make a water sticker with a foam layer;

[0016] The production steps of the foaming layer are to dissolve the foaming powder into ink or varnish to prepare foaming ink, and then screen-print the foaming ink on the backing paper to form a foaming layer. The pattern of the foaming layer can be protruded according to the three-dimensional pattern It needs to be designed and manufactured, which corresponds to the protruding position setting of the three-dimensional pattern. The selection of screen mesh should comprehensively consider the fineness, pattern size, characteristics of foaming ink, etc., and 80-120 mesh can be used. The water sticker with the foam layer can be made by adding the step of making the foam layer into the existing water sticker manufacturing process. The manufacturing step of the foam layer can be before, after or during...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com