Car body sound vibration roughness NVH design method based on low frequency acoustic sensitiveness inside vehicle

A design method and sensitivity technology, which is applied in the field of NVH design of vehicle body acoustic vibration roughness based on low-frequency interior acoustic sensitivity, and can solve problems that have yet to be studied in engineering practice

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

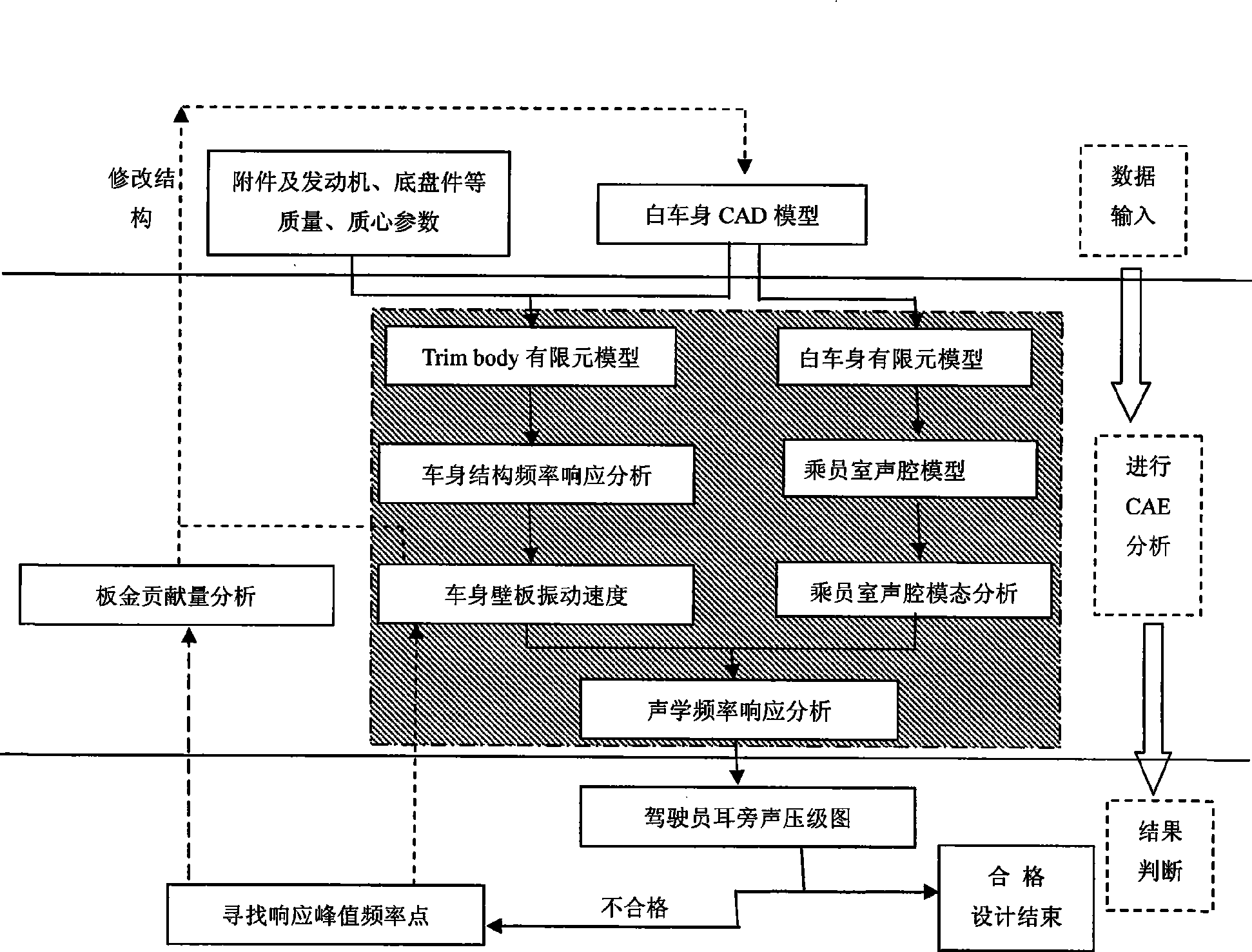

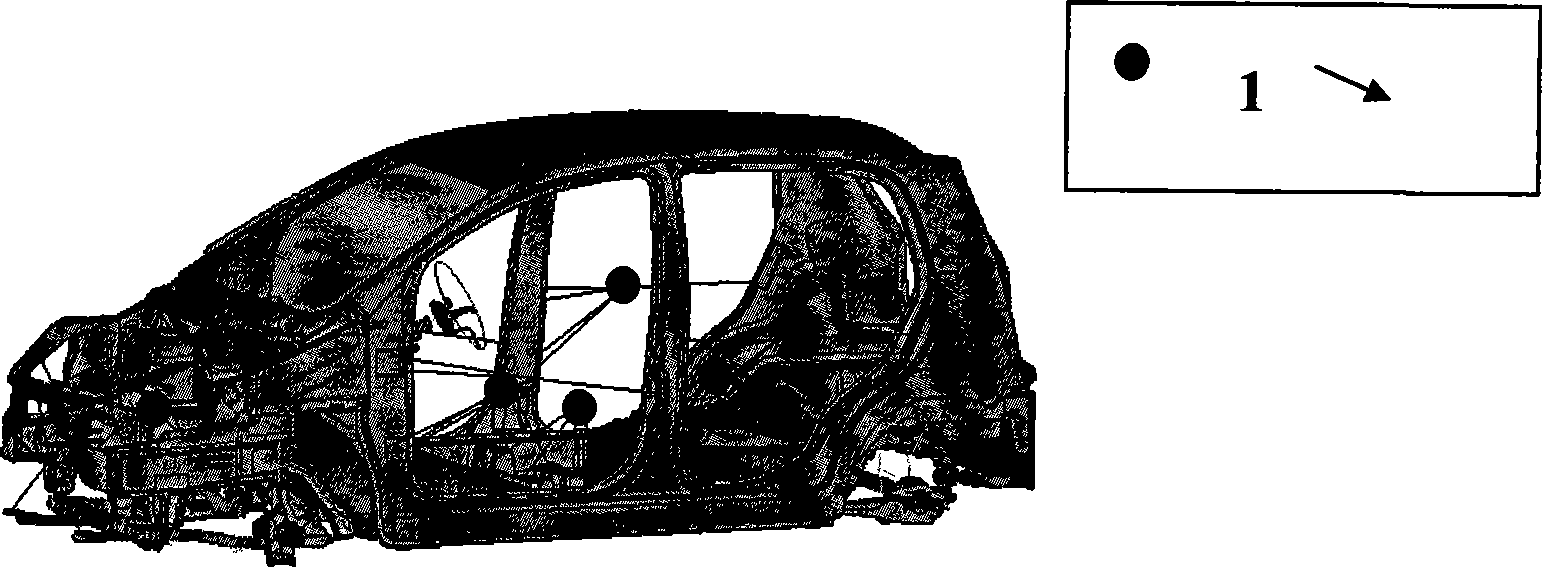

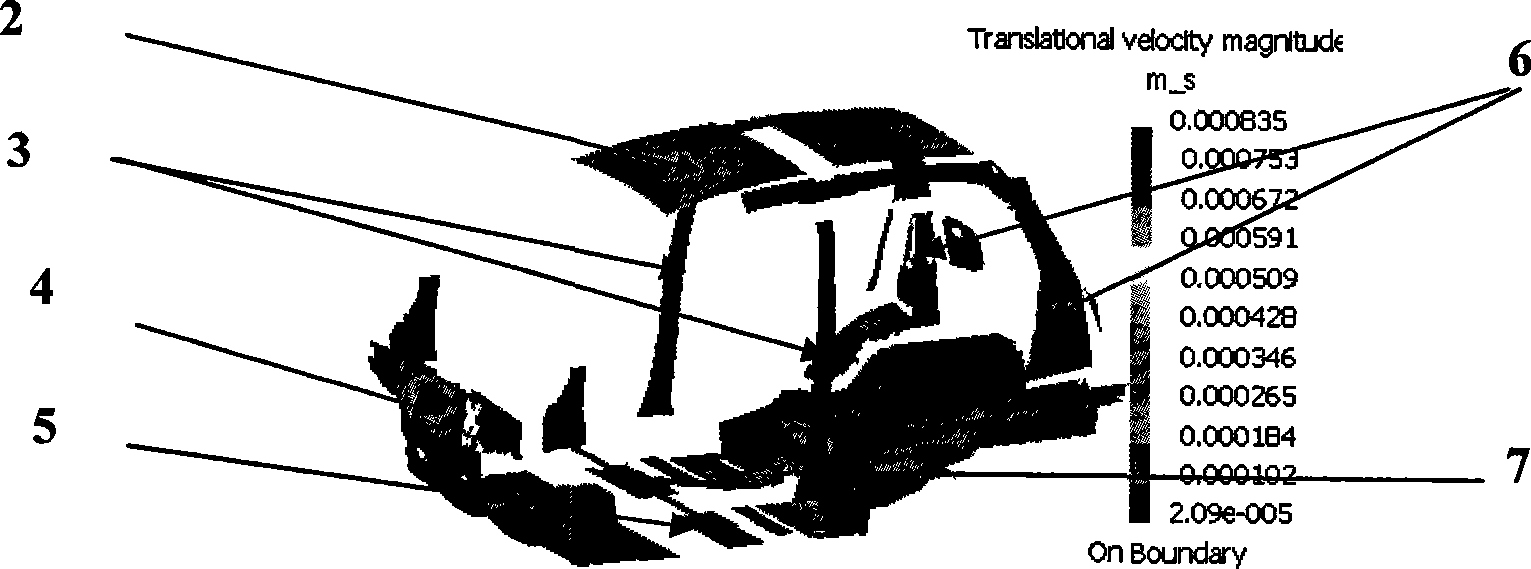

[0034] figure 1 The acoustic sensitivity analysis flow is given. Firstly, the BIW finite element model is established, and the acoustic finite element model of the passenger compartment is established based on the BIW model; the frequency response analysis of the engine suspension points, suspension installation points, exhaust suspension points, etc. on the body is carried out; and then Using the vibration velocity of the body panel obtained from the frequency response analysis as a boundary condition, the acoustic response of the passenger compartment acoustic cavity is solved to obtain the sound pressure level next to the driver's ear; and then by checking the frequency response analysis results at the frequency point with a higher sound pressure response According to the vibration situation of the car body panel and the contribution of the sheet metal, the influence level and the installation point of the sheet metal parts that have a greater impact on the sound pressure l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com