Carryover apparatus

A technology of moving and rolling beds, which is applied in the direction of conveyor control devices, transportation and packaging, and conveyor objects. It can solve the problems of logistics crossover, achieve convenient maintenance, solve logistics crossover problems, and reduce costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

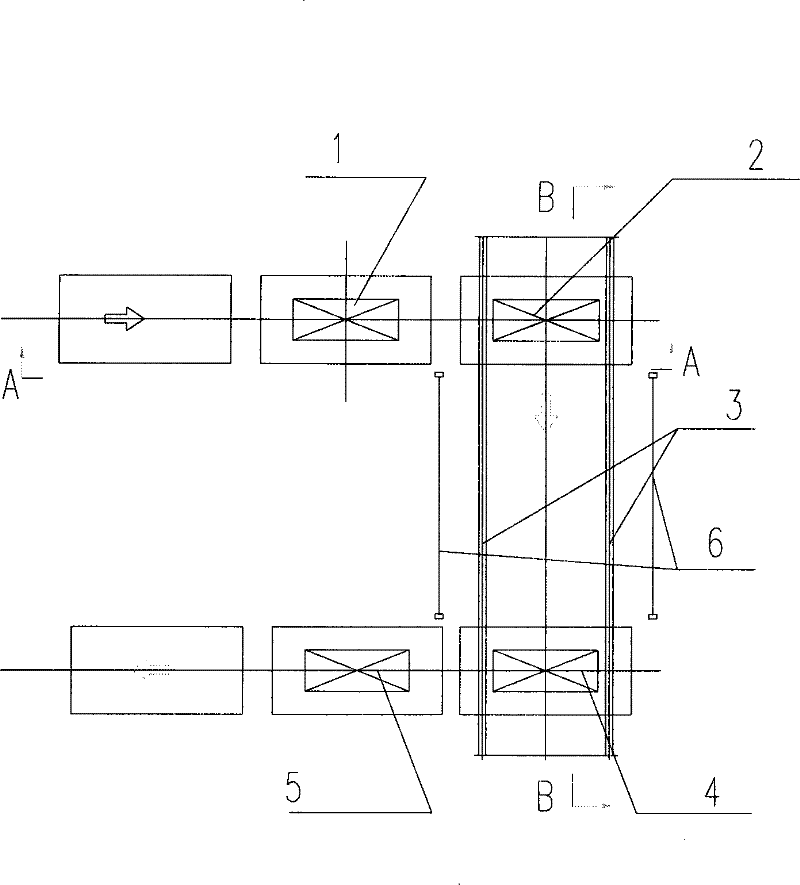

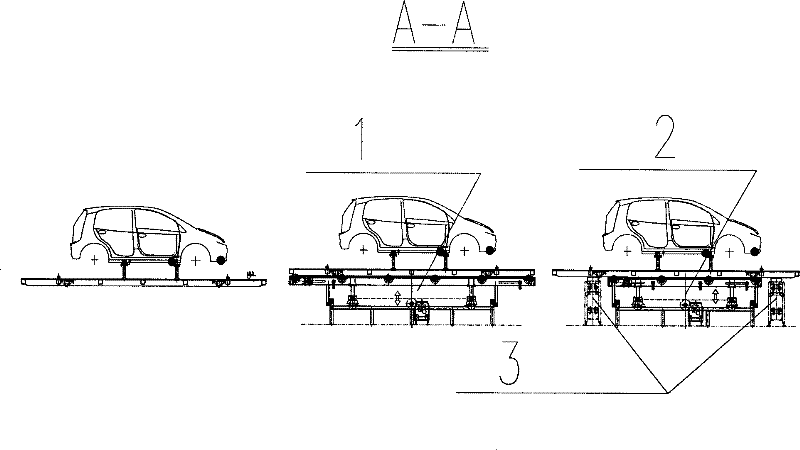

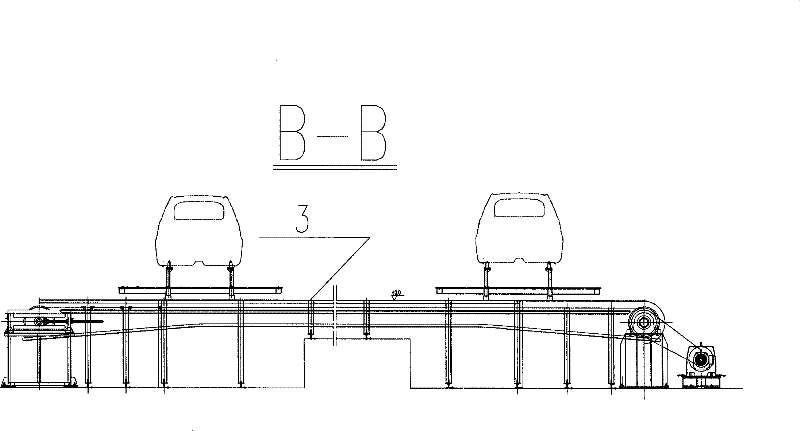

[0024] The present invention will be described in detail below according to the accompanying drawings, which is a preferred embodiment among various implementations of the present invention.

[0025] The invention discloses a new type of wide push plate traveling device, which comprises eccentric lifting roller bed 1, eccentric lifting roller bed 2, traveling plate chain 3 with bosses, eccentric lifting roller bed 4, and eccentric lifting roller bed 5 , Safety grating 6. The specific implementation method is: add the above six sets of devices at the end of the wide push plate conveyor line, including eccentric lifting roller bed 1, eccentric lifting roller bed 2, traveling plate chain with boss 3, eccentric lifting roller bed 4, eccentric lifting roller bed Lifting roller bed 5 is main function part. After the eccentric lifting roller bed 1 is lowered, it accepts the wide push plate conveyed by the conveyor line and sends the wide push plate to the eccentric lifting roller be...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com