Spherical hinge rubber elastic element stiffness changing method and spherical hinge rubber elastic element

A technology of elastic element and rubber elastic body, which is used in elastic shock absorbers, railway car body parts, railway couplings, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

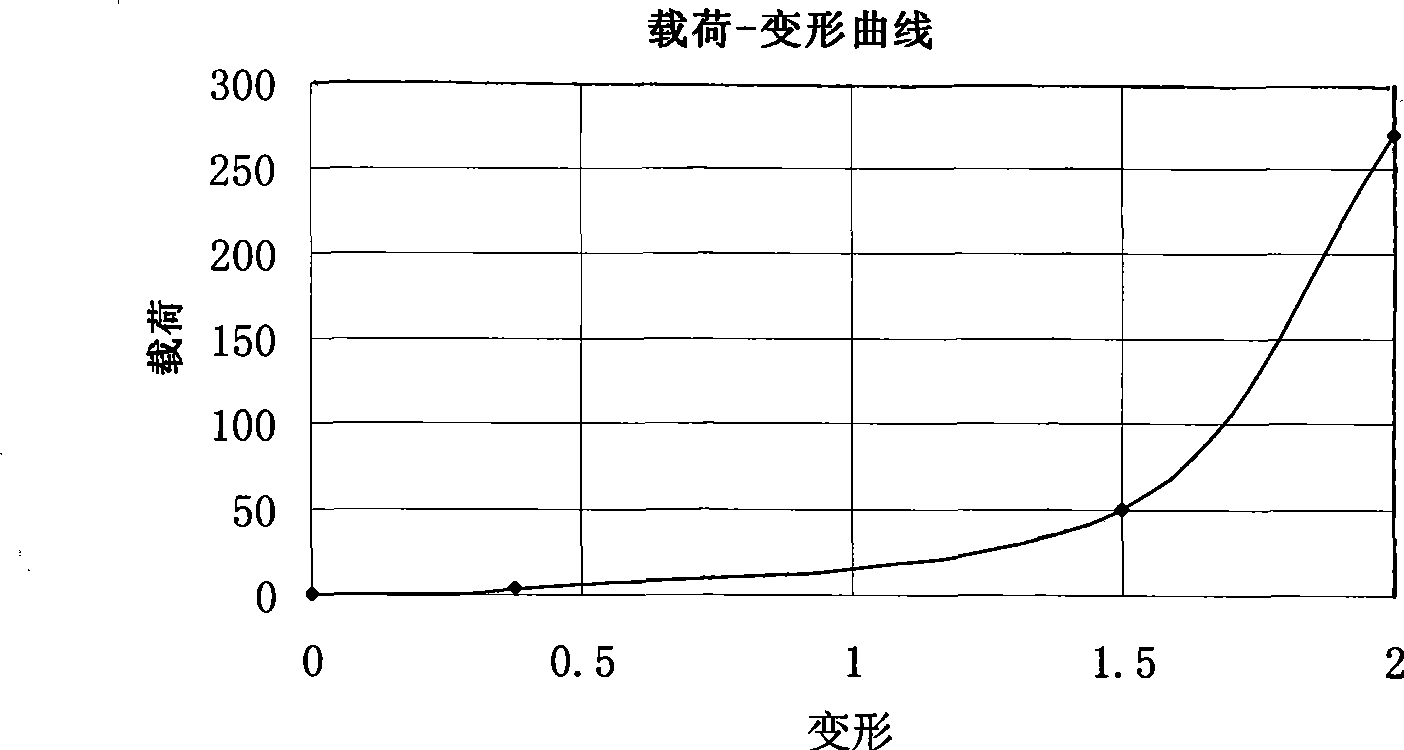

[0034] From attached Figure 4 -5, it can be seen that the ball joint type rubber elastic element is composed of A ball joint 2, B ball joint 3 and mandrel 1; wherein, A ball joint 2 is two pieces, B ball joint 3 is one piece; A The ball joint 2 and the B ball joint 3 are both sleeved on the mandrel 1, and the B ball joint 3 is located between the two A ball joints, and the A ball joint part and the B ball joint part are elastic ball joints with different structures and different rigidities . attached Figure 6 It is a schematic diagram of the split structure of this embodiment.

[0035] Among them, such as Figure 4 and Figure 7 As shown, the A ball joint 2 is composed of the A ball joint metal inner sleeve 4, the A ball joint rubber elastic body 5 and the A ball joint metal outer sleeve 6, and the A ball joint rubber elastic body 5 is located between the A ball joint metal inner sleeve 4 and the A ball joint Between the hinge metal jackets 6, and the inner surface of t...

Embodiment 2

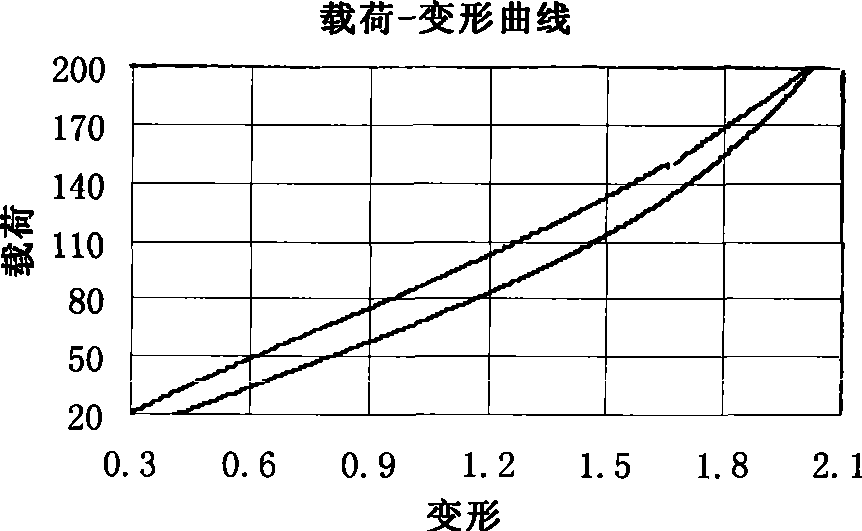

[0038] attached Figure 13 -14 is another embodiment of the present invention, the structure of embodiment two and embodiment one is basically similar, just increased spacer 16 in the rubber elastic body of A ball joint 2, for the branch similar to B ball joint 3 With the petal structure, the number of spacers 16 can be adjusted according to needs, so that the product performance of variable stiffness can also be obtained, but compared with the first embodiment, a relatively steep stiffness curve of the first stage can be obtained.

Embodiment 3

[0040] attached Figure 15 As another embodiment of the present invention, the structure of the third embodiment is similar to that of the first embodiment, except that the middle split metal spacer 10 is omitted from the B spherical joint elastic rubber body 9, so that the product performance of variable stiffness can also be obtained. However, compared with the first embodiment, a relatively gentle stiffness curve of the second stage can be obtained.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com