An inertial adjustable low frequency vibration isolation device

A vibration isolation, low frequency technology, applied in the field of inertial adjustable low frequency vibration isolation devices, can solve the problems of inconvenient adjustment of the quality of the shock absorption system, and the inability of the shock absorption system to effectively suppress the low frequency vibration, so as to reduce the influence of basic vibration and reduce the Effect of resonance frequency, low resonance frequency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

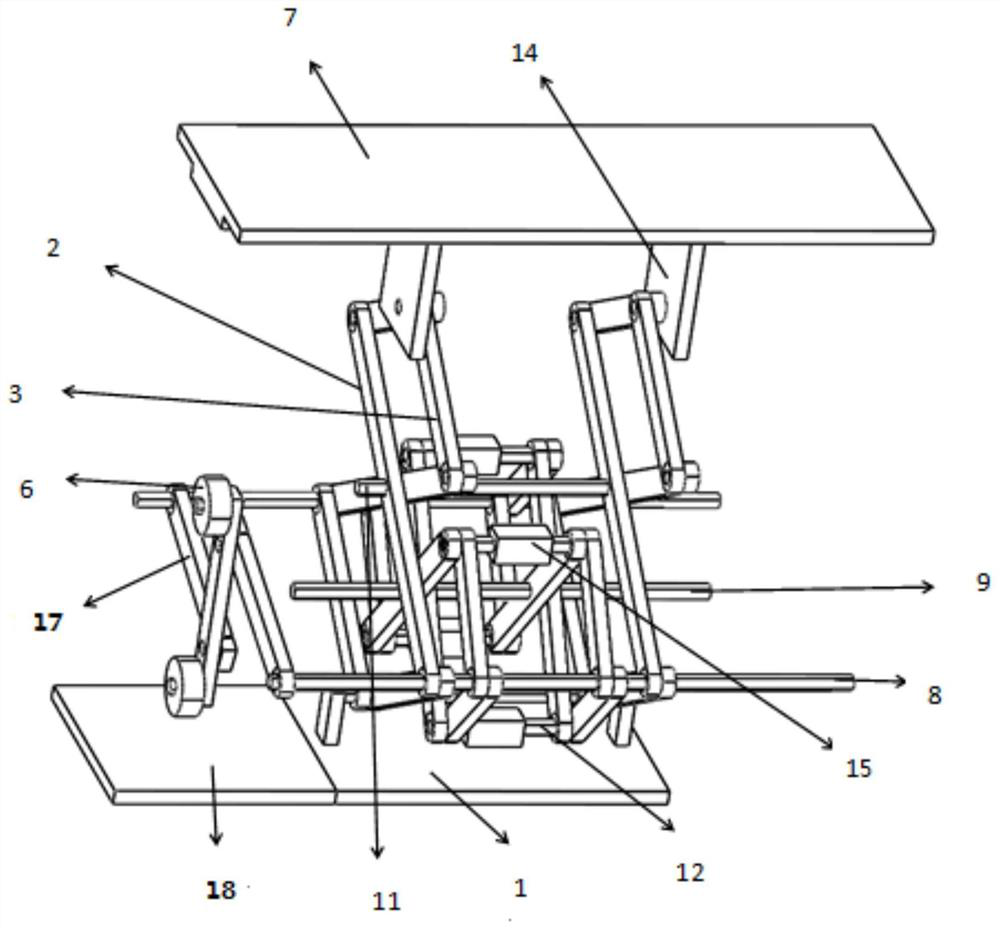

[0026] Specific implementation mode one: refer to Figure 1 to Figure 5 Describe this embodiment. This embodiment provides an inertial adjustable low-frequency vibration isolation device. The vibration isolation device includes a base 1, a supporting plate 7, a shock absorbing mechanism, and a counterweight mechanism. Relatively arranged, the supporting mechanism is arranged between the base 1 and the supporting plate 7, and one end of the supporting mechanism is fixedly connected with the base 1, the other end of the supporting mechanism is fixedly connected with the supporting plate 7, and the shock absorbing mechanism is arranged inside the supporting mechanism, and The damping mechanism is fixedly connected with the support mechanism, the counterweight mechanism is arranged on one side of the support mechanism, and the counterweight mechanism is fixedly connected with the support mechanism.

[0027] In this embodiment, the base 1 and the supporting mechanism mainly play a ...

specific Embodiment approach 2

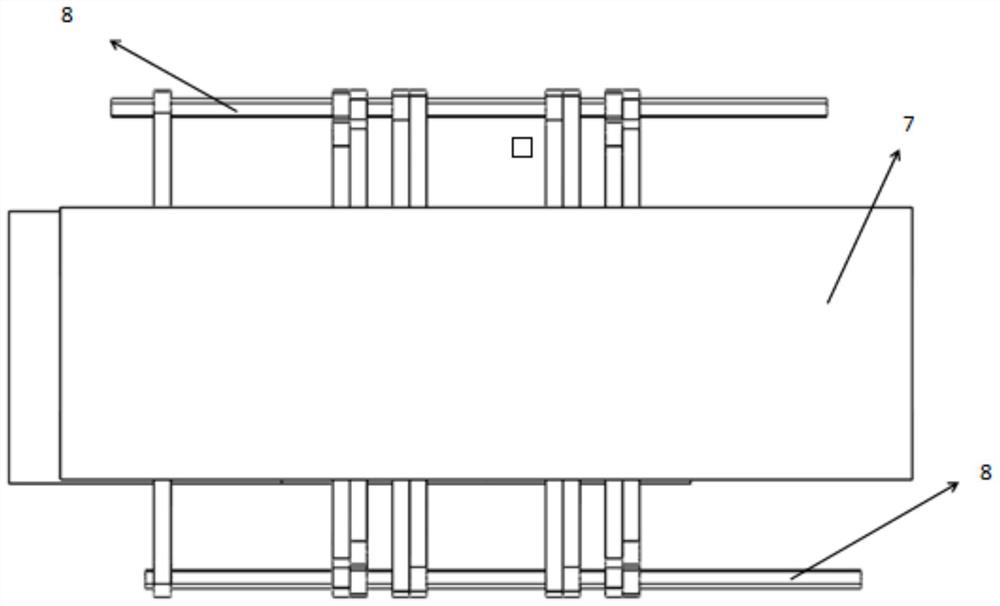

[0028] Specific implementation mode two: refer to Figure 1 to Figure 5Describe this embodiment, this embodiment is to further limit the support mechanism described in the first embodiment, in this embodiment, the support mechanism includes the third cylindrical connecting rod 10, the fourth cylindrical connecting rod 11, two one No. cylindrical connecting rod 8, two L-shaped rigid plates 14, two rigid support plates 16 and two supporting trusses, the supporting trusses are "8"-shaped frames, and the two supporting trusses pass through No. 3 cylindrical connecting rods 10 , No. 4 cylindrical connecting rod 11 is connected with two No. 1 cylindrical connecting rods 8, No. 4 cylindrical connecting rod 11 is set at the center of two supporting trusses, and the two ends of No. 3 cylindrical connecting rod 10 respectively pass through a supporting truss and connect with it Rotationally connected, the two No. 1 cylindrical connecting rods 8 are all arranged on the lower part of the ...

specific Embodiment approach 3

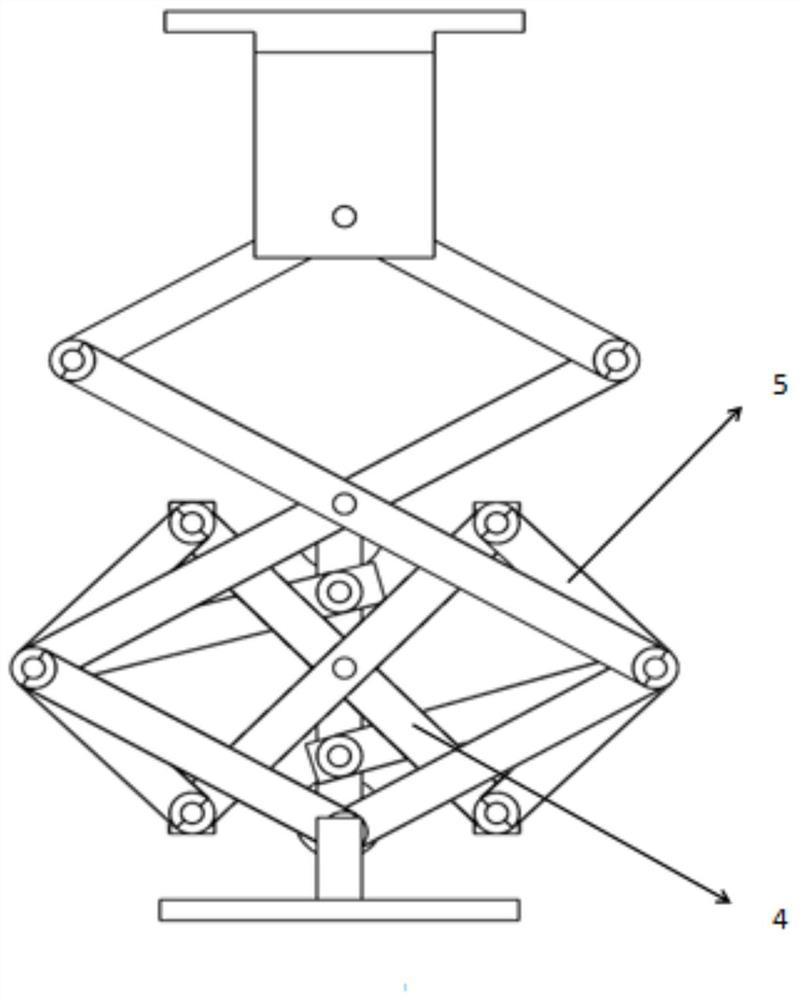

[0030] Specific implementation mode three: refer to Figure 1 to Figure 5 Describe this embodiment, this embodiment is to further limit the support truss in the second specific embodiment, in this embodiment, the support truss includes two No. 1 three-hole long rods 2 and four No. 1 two-hole short rods 3. Two No. 1 three-hole long rods 2 are arranged in an X shape, and two No. 1 three-hole long rods 2 are hinged, and two No. 1 two-hole short rods 3 of the four No. 1 two-hole short rods 3 are set on Above the two No. 1 three-hole long rods 2, one end of the No. 1 two-hole short rod 3 in the two No. 1 two-hole short rods 3 is hinged with one end of the other two-hole short rod 3, and two No. 1 two-hole short rods 3 are hinged. The other end of each No. 1 two-hole short rod 3 in the short rod 3 is hinged with one end of a No. 1 three-hole long rod 2, and the other two No. 1 two-hole short rods in the four No. 1 two-hole short rods 3 are hinged. 3 is arranged below the two No. 1 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com