Testing device for implementing main torque and vibrating torque to high speed rotary main shaft

A test device and spindle technology, applied in the direction of mechanical bearing testing, etc., can solve the problems of not being able to simulate high-speed rotating spindles at the same time, the structure of the test device being complex, and the inability to compound loading, etc., and achieve the effects of simple structure, easy manufacturing and low manufacturing cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

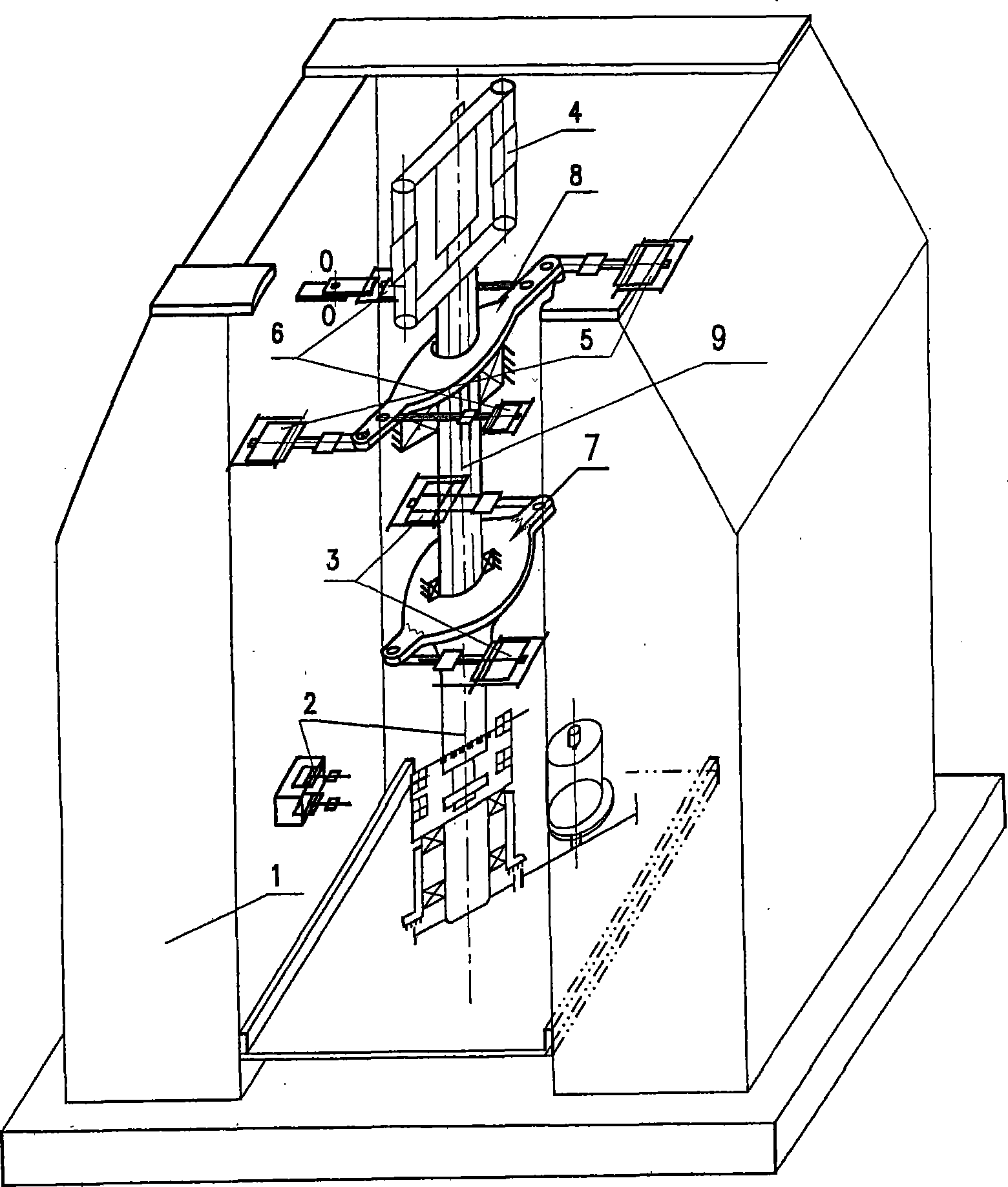

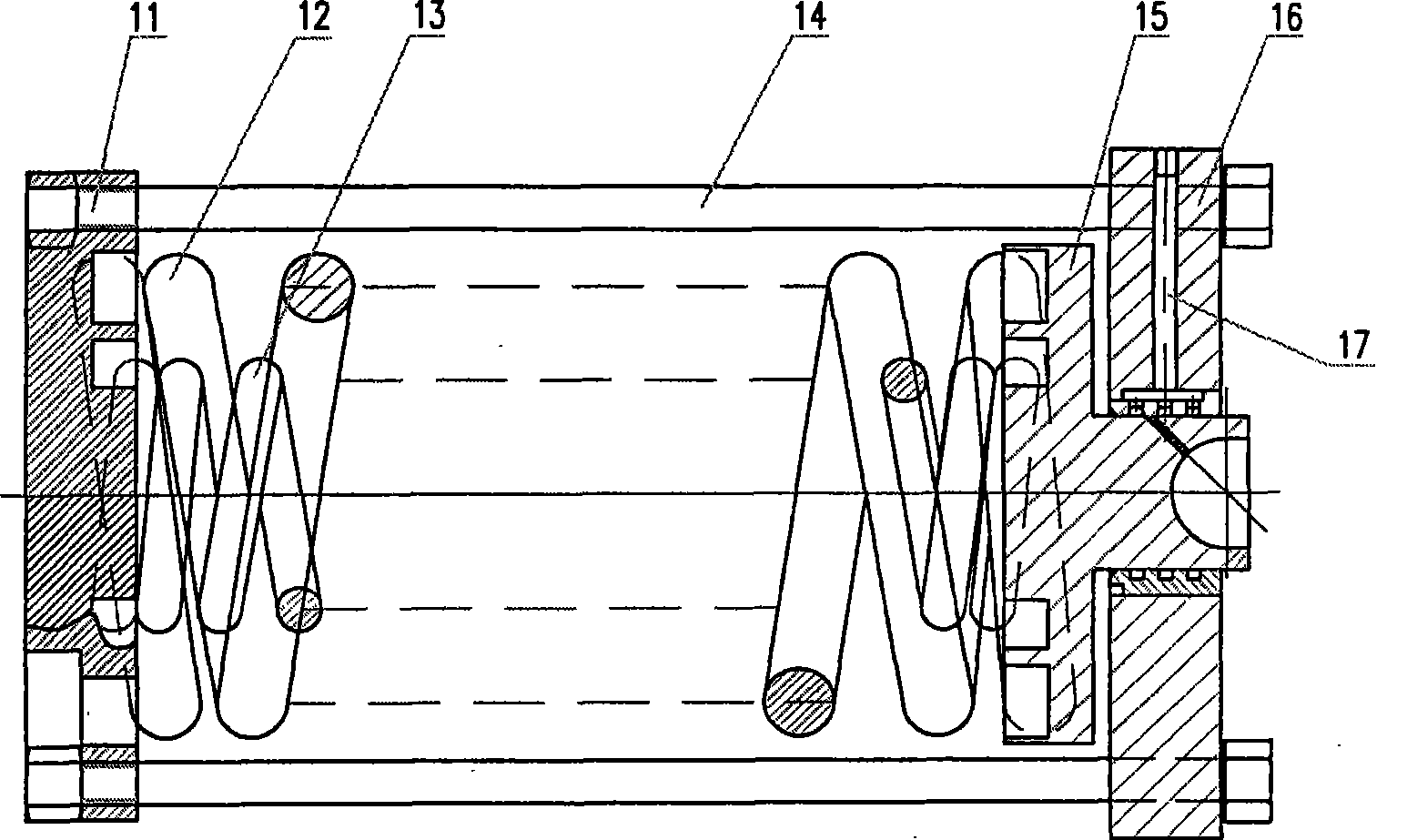

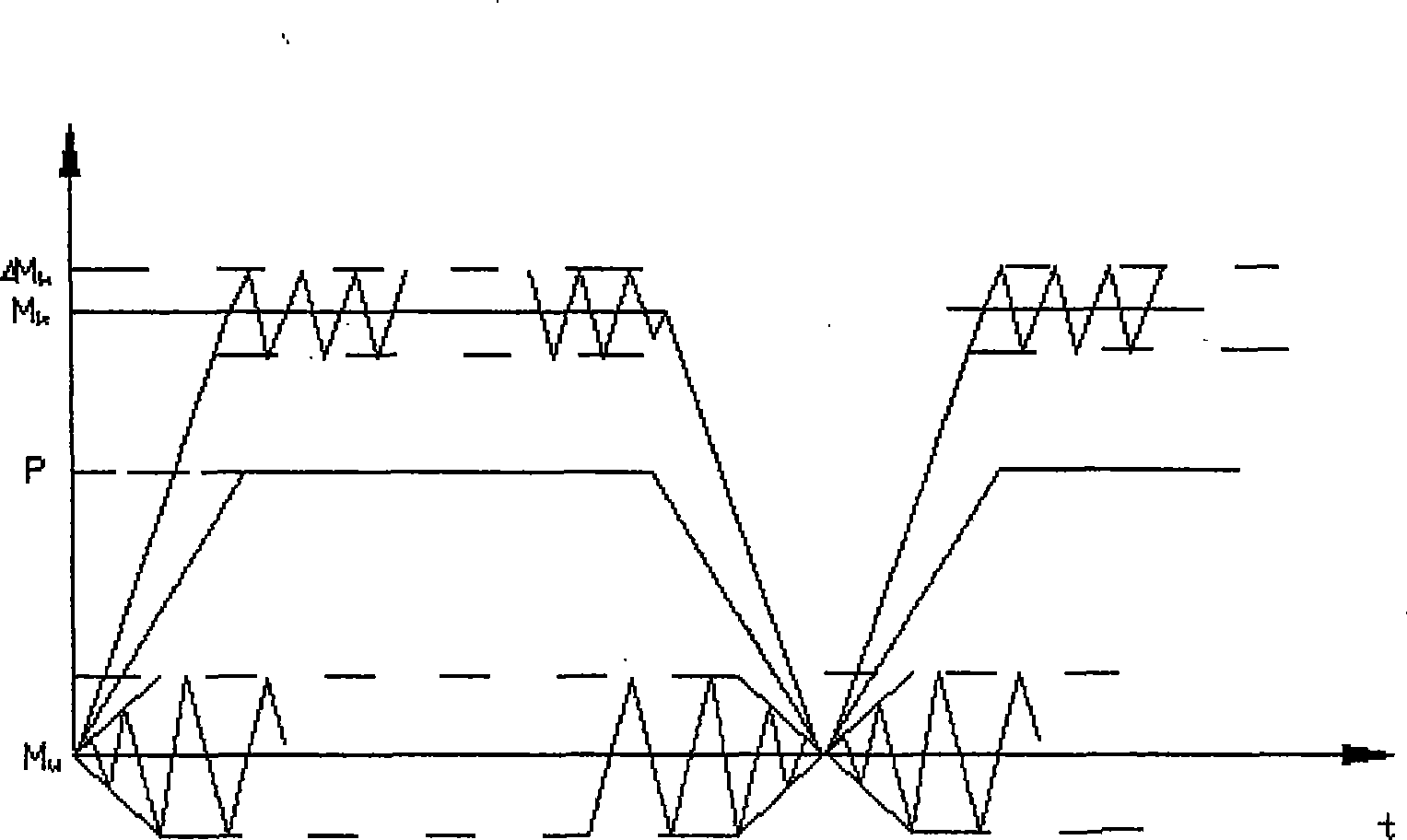

[0030] This embodiment provides a test device capable of implementing main torque and vibration torque on a high-speed rotating spindle, and its structure is as attached figure 1 As shown in the figure, by the device frame 1, the main torsion arm 7, the anti-torsion arm 9, the force constitutes the main torsion couple of 2 main torsion actuator mechanisms 4, and the force constitutes the vibration torsion couple of 2 vibration actuators The mechanism 5 is composed of two spring anti-twist actuating mechanisms 6 whose reaction force constitutes a anti-torque couple, and a hydraulic servo system that controls four actuating cylinder mechanisms by four electromagnetic hydraulic servo valves respectively. The two main torsion actuator mechanisms, the two vibration actuator mechanisms and the two spring anti-twist actuator mechanisms are all arranged symmetrically. The device frame 1 is a gantry structure, consisting of a base, two wall columns and beams. The main torsion arm 7 and th...

Embodiment 2

[0032] This embodiment provides a test device capable of implementing main torque and vibration torque on a high-speed rotating spindle. The structure is as attached figure 1 And figure 2 As shown, its structure is basically the same as that of embodiment 1, the difference is that on the basis of embodiment 1, a bending moment loading mechanism 2 and an axial force loading mechanism 10 are added to the test device. The bending moment loading mechanism passes a bending moment loading shaft 3 Connected with the rotating shaft test piece, the axial force loading mechanism directly acts on the rotating shaft test piece. The other structure is the same as that of Example 1. The test device of this embodiment can not only simulate the main torque load and high-frequency vibration load under the running state of the high-speed rotating spindle completely and truly, but also simulate the bending moment load and the axial load. Perform comprehensive tests under various loads.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com