Improved structure of drafting device in ribbon lap machine

A technology of drafting device and winding machine, which is applied in the direction of drafting equipment, spinning machines, textiles and papermaking, etc. It can solve the problems of complex drafting structure of sliver and lapping machine, achieve improved drafting effect, simple mechanism and convenient The effect of working parameters

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

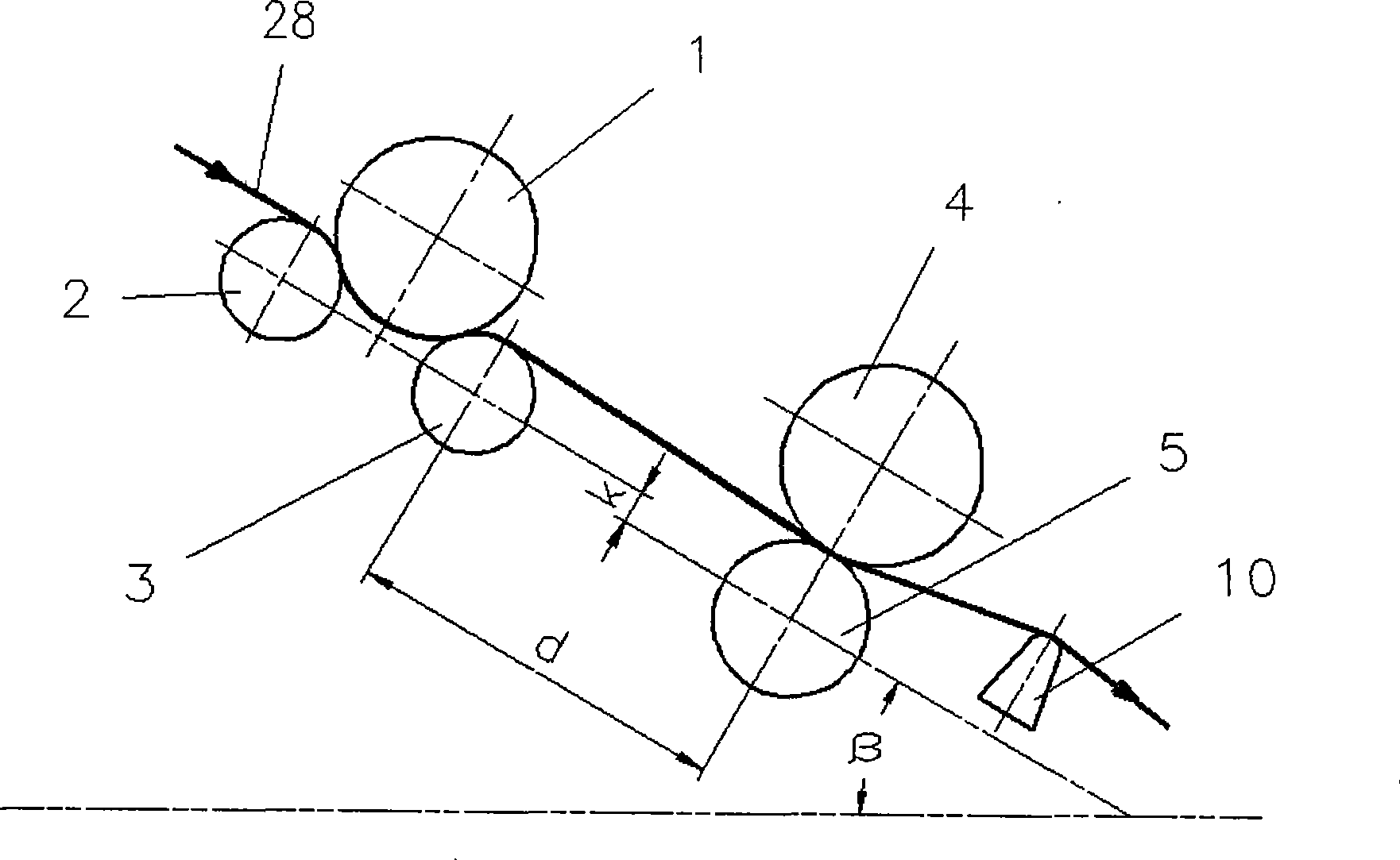

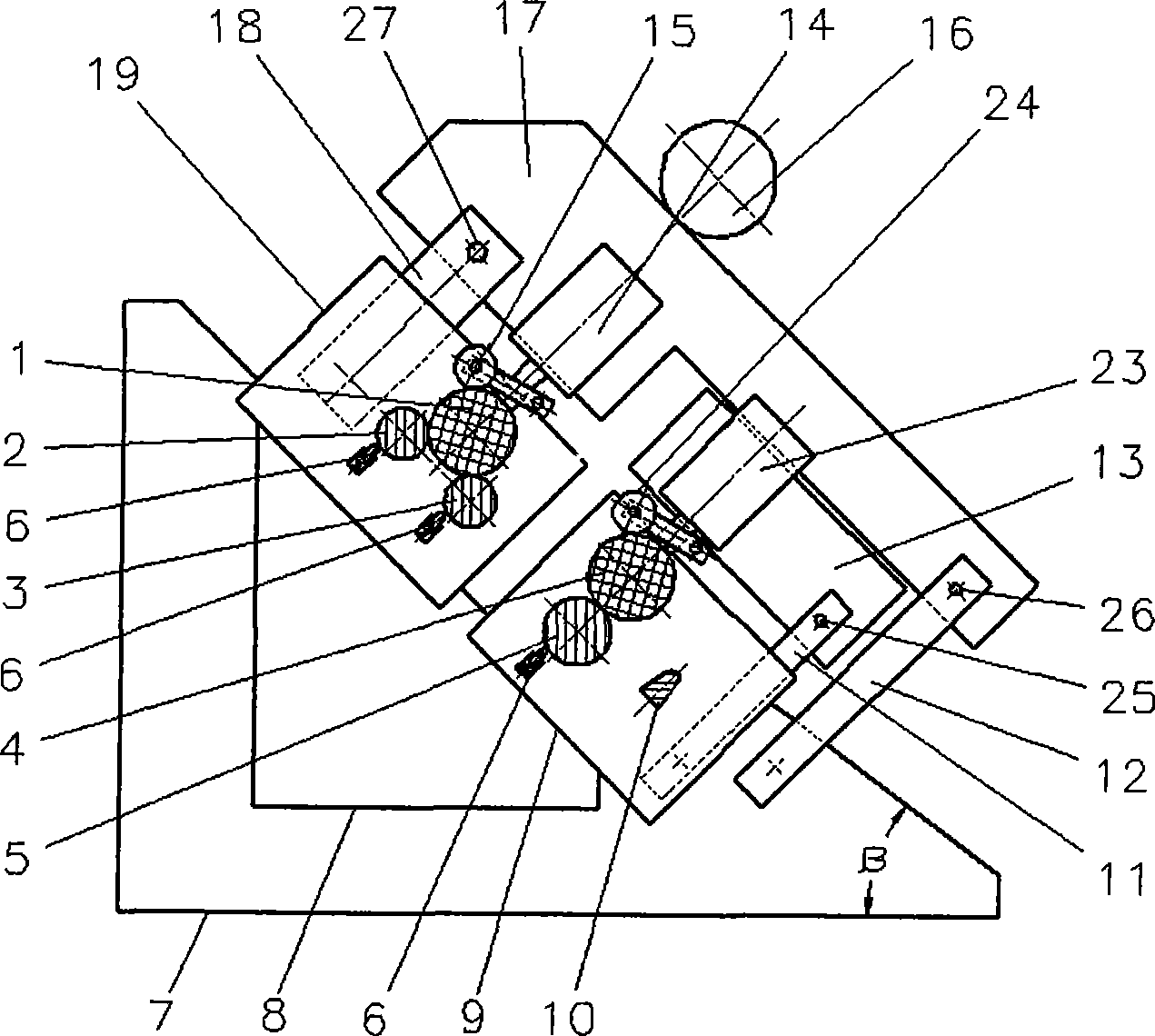

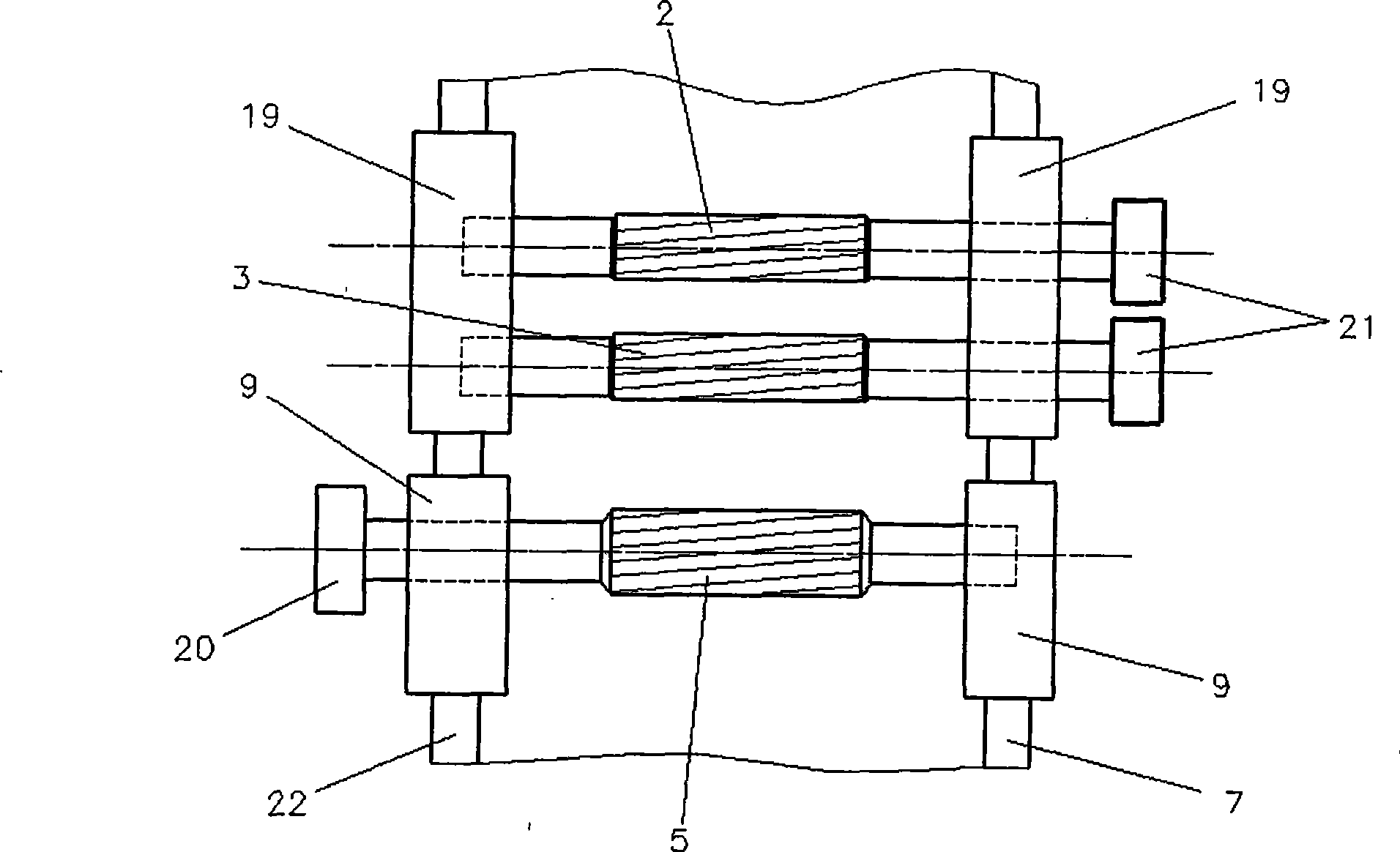

[0024] Such as figure 1 , figure 2 , image 3 and Figure 4 As shown, the improved structure of the drafting device in a sliver doubling machine of the present invention is composed of a support plate 7 and a support plate 22, and the support plate 7 and the support plate 22 are arranged in parallel and at intervals, wherein the support plate 7 and the support plate 22 are all in the form of Right-angled triangle, a connecting rod (not shown) is arranged between the support plate 7 and the support plate 22, and a first roller seat 19 and a second roller seat are respectively arranged on the hypotenuses of the support plate 7 and the support plate 22 9. There is a gap between the first roller seat 19 and the second roller seat 9, and a displacement adjustment mechanism (not shown in the figure) is provided between the second roller seat and the hypotenuse of the support plate 7 and the support plate 22. ), a first metal roller 2 and a second metal roller 3 are arranged in t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com