Scaffold

A scaffolding and racking technology, applied in the field of scaffolding, can solve the problems of increased construction cost, high overall cost, complex process, etc., and achieve the effects of improving the overall load capacity, short cutting time, and simple and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

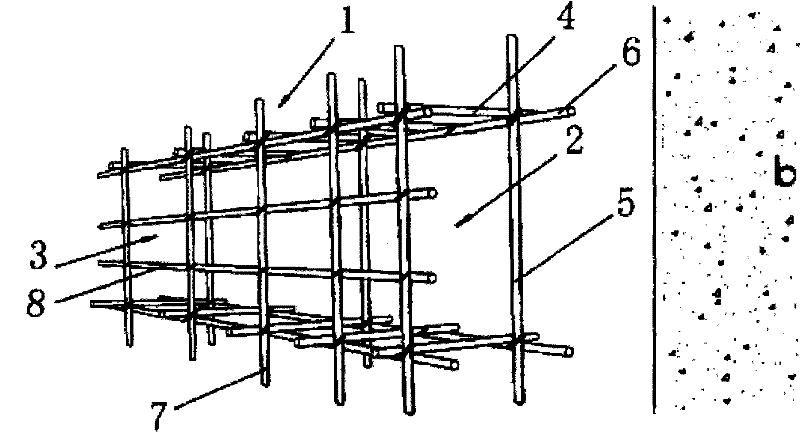

[0027] See figure 1 , which is a perspective view of the scaffold provided by the embodiment of the present invention, which shows the main structure of the scaffold.

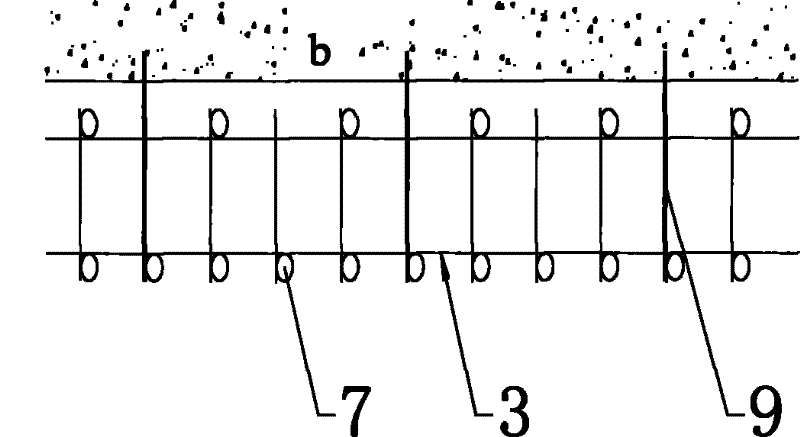

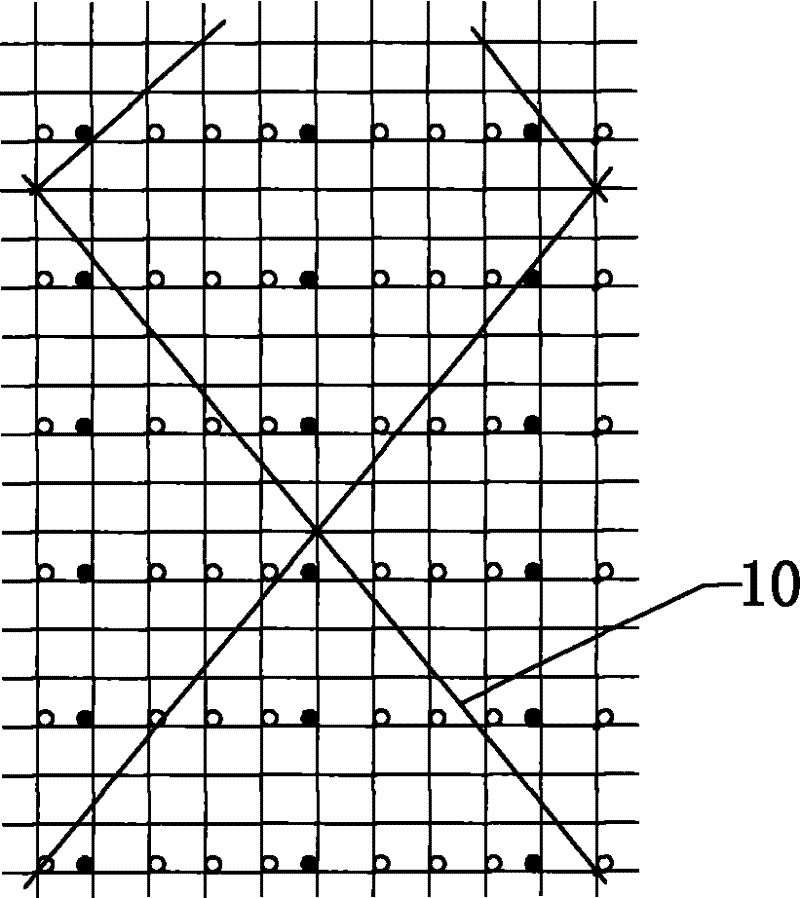

[0028] The basic structure of the scaffolding 1 comprises an inner row frame body 2, an outer row frame body 3, and a small cross bar 4, the inner row frame body 2 is arranged close to the building b, and the outer row frame body 3 is arranged away from the building. The cross bar 4 is arranged between the inner and outer bent frames 2, 3, and is used for the connection of the two. The inner row frame body 2 includes inner upright bars 5 and inner cross bars 6 arranged vertically and horizontally, and the outer row frame body 3 includes outer vertical bars 7 and outer horizontal bars 8 arranged vertically and horizontally.

[0029] Since the scaffolding 1 mainly relies on the outer row frame body 3 for load bearing, the outer row frame body 3 needs to be constructed by selecting metal pipes or hard resin pipes...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com