Structure improvement of electromagnetic pump

A pumping and electromagnetic technology, applied in the direction of pumps, pumps with flexible working elements, liquid variable capacity machinery, etc., can solve problems such as insufficient suction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] In order to make your examiner and those who are accustomed to this technique have a further understanding of the present invention, a preferred embodiment is given hereafter, and the details are as follows: (but, this embodiment is only beneficial to explanation, and the future development of the present invention Implementation is not limited to this, and all improvements and implementations based on the technical features of the present invention are bound by the present invention).

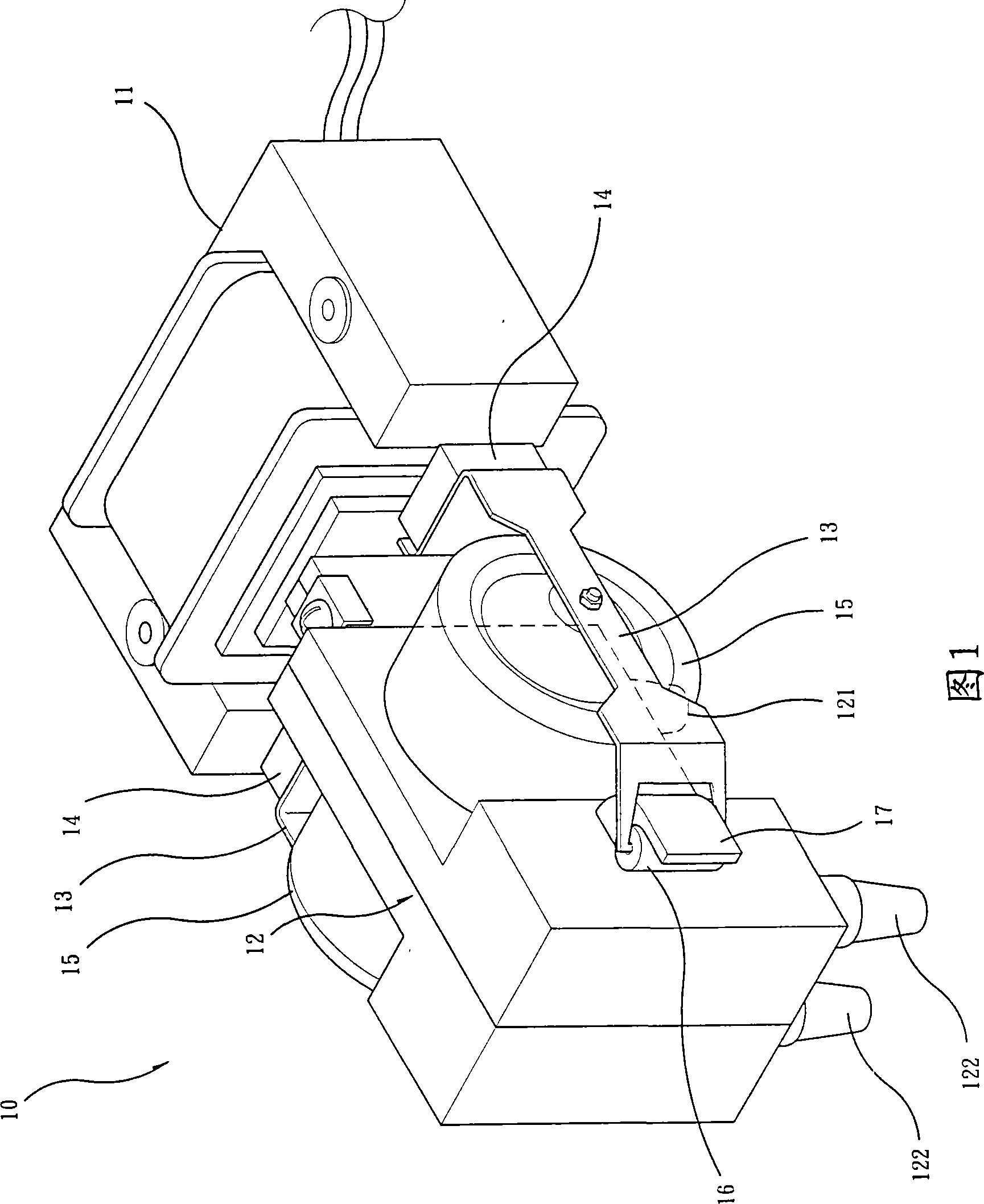

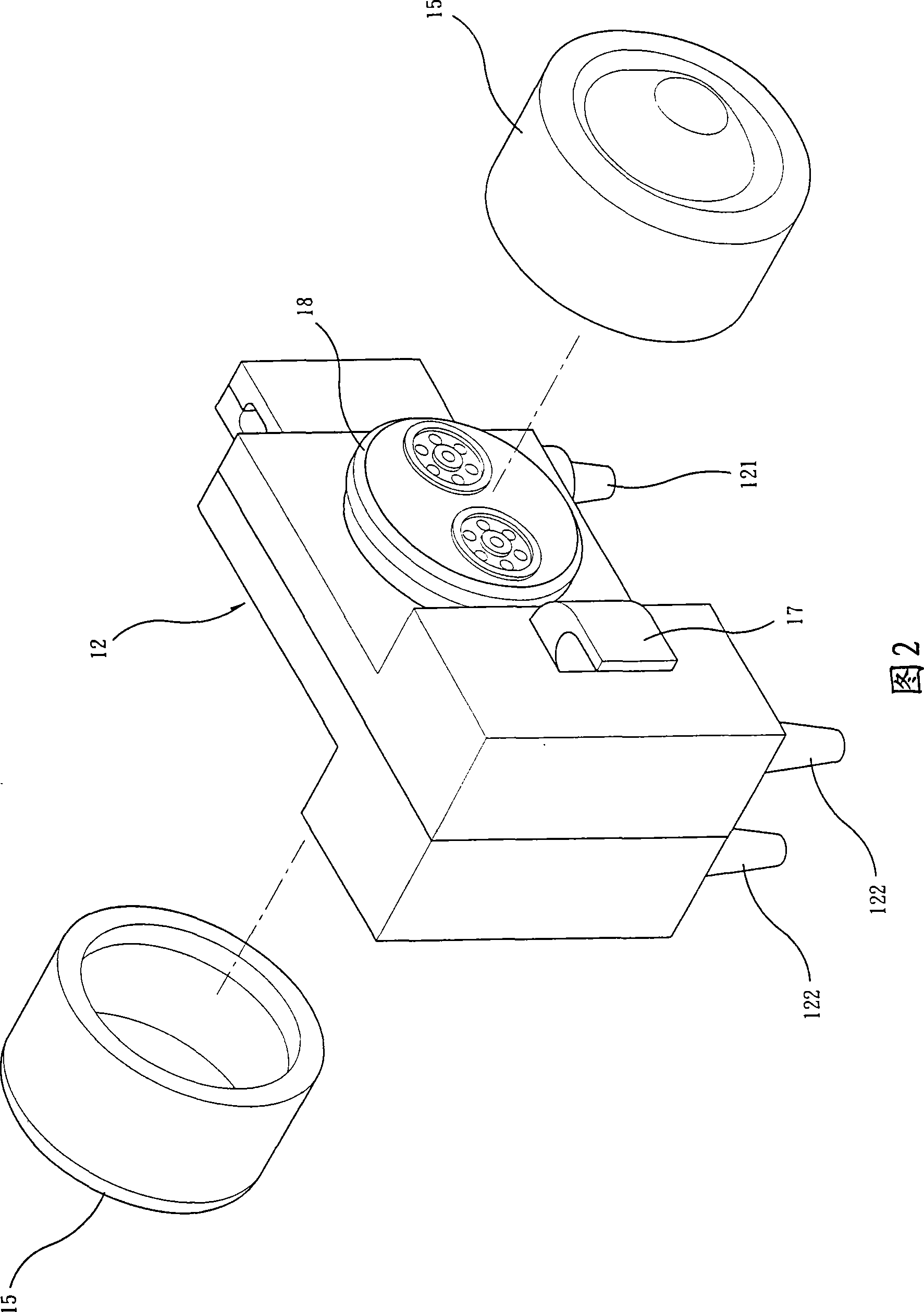

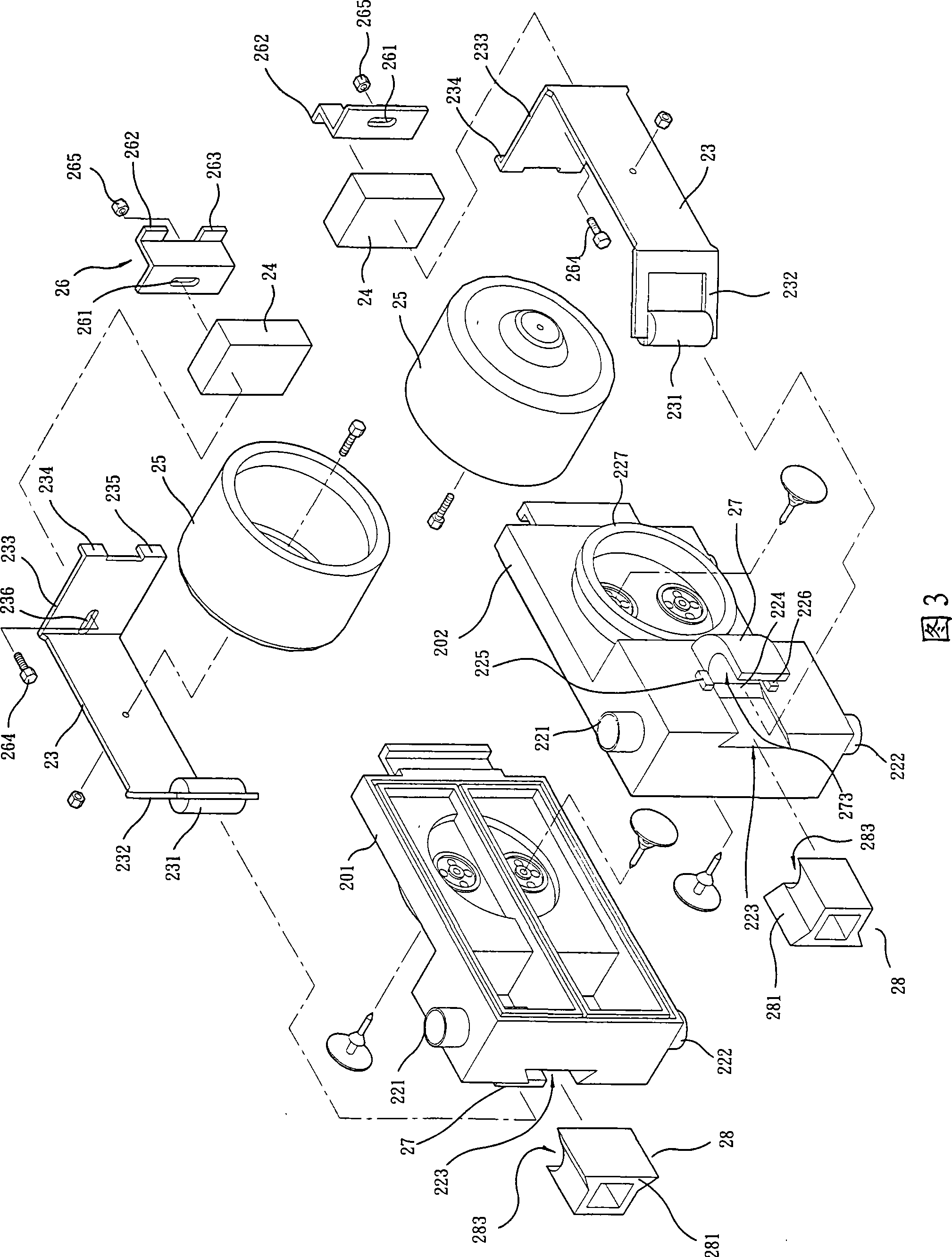

[0044]Please refer to Fig. 3 to Fig. 6, the air chamber 22 of the electromagnetic pump 20 of this embodiment is formed by the first shell 201 and the second shell 202 being fixed together, the first shell 201, the second shell Body 202 is made of wear-resistant material, and the wear-resistant material can be plastic steel, ceramics, Teflon, the inner compartment of the air chamber 22 is divided into two inner spaces, and one to several input conduits 221 and output conduits are provided...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com