Buried type ground surface safety protection structure and buried type garbage collection device

A safety protection, buried technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The embodiments of the present invention will be described in detail below with reference to the accompanying drawings, but the present invention can be implemented in a variety of different ways defined and covered by the claims.

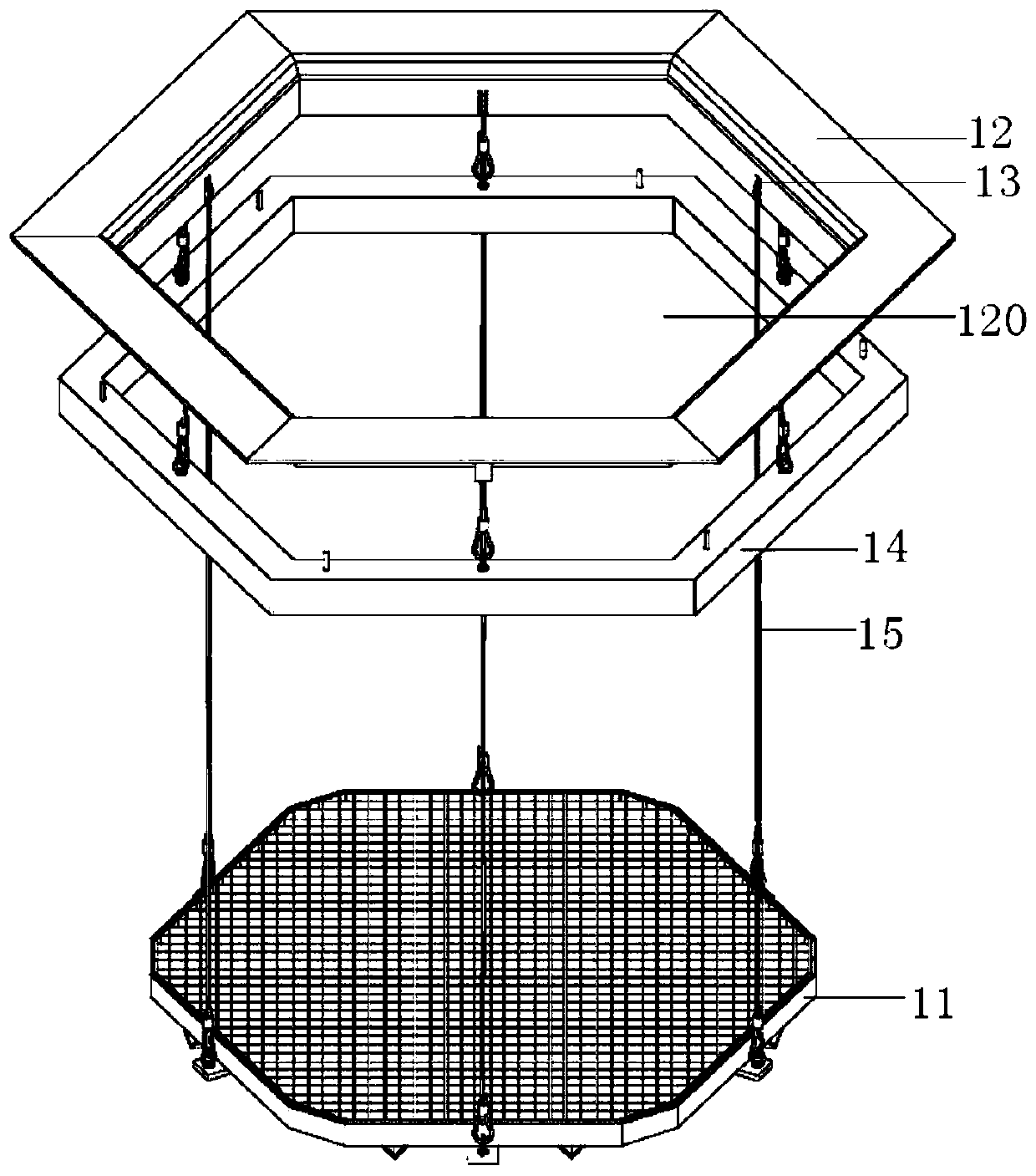

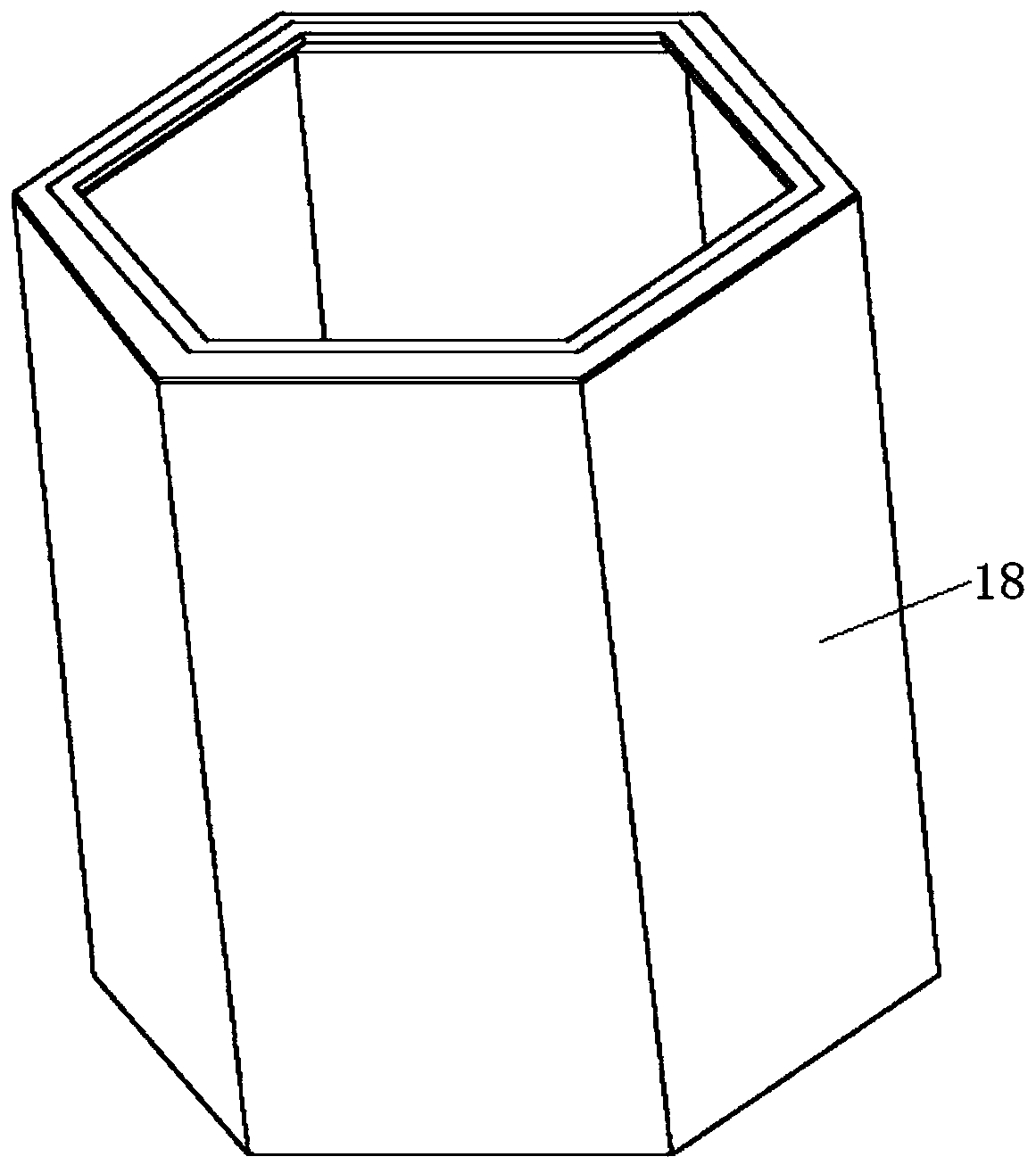

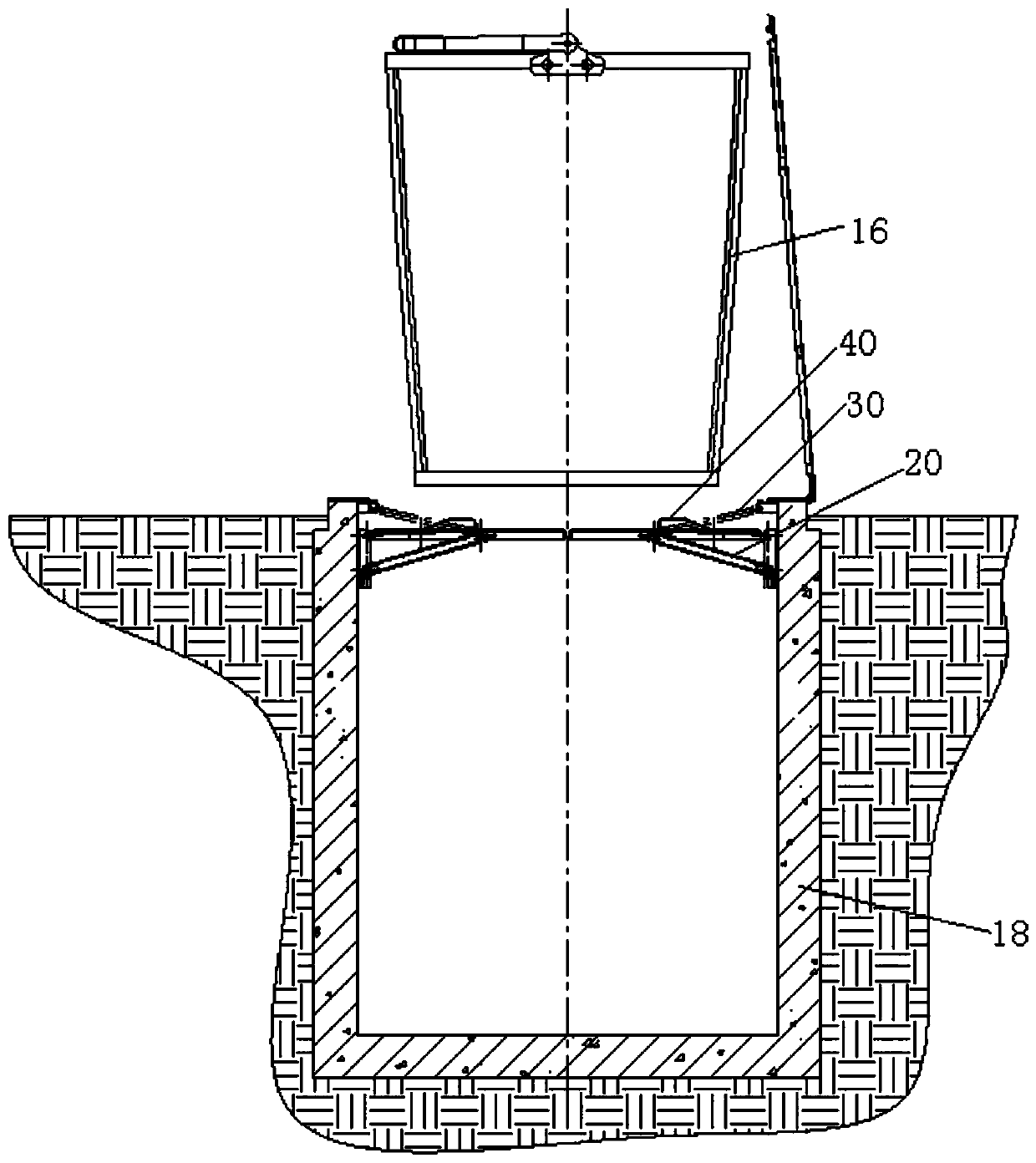

[0034] Reference image 3 with Figure 4 , The preferred embodiment of the present invention provides an in-ground ground safety protection structure, including: two sets of protection components arranged oppositely and fixedly connected to the inner wall of the open end of the buried outer barrel 18, each group of protection components including triangular connections Structure 20. The triangular connecting structure 20 is used to form a stable and locked triangular structure after the trash can 16 is filled with the buried outer barrel 18, so that two corresponding triangular structures cooperate to form a protective platform to seal the buried outer barrel. The open end of 18 prevents people from falling into the buried outer barrel 18. Each...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com