Diverter for grounding wire

A technology of steering gear and grounding wire, which is applied in the direction of connection, conductive connection, and electrical component connection, etc. It can solve the problems of difficulty in hanging and removing the grounding wire of the tension tower, inconvenient mounting and detaching of the grounding wire, and inability to use it, so as to achieve saving The effect of manpower and labor intensity, convenient operation, and accurate mounting process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

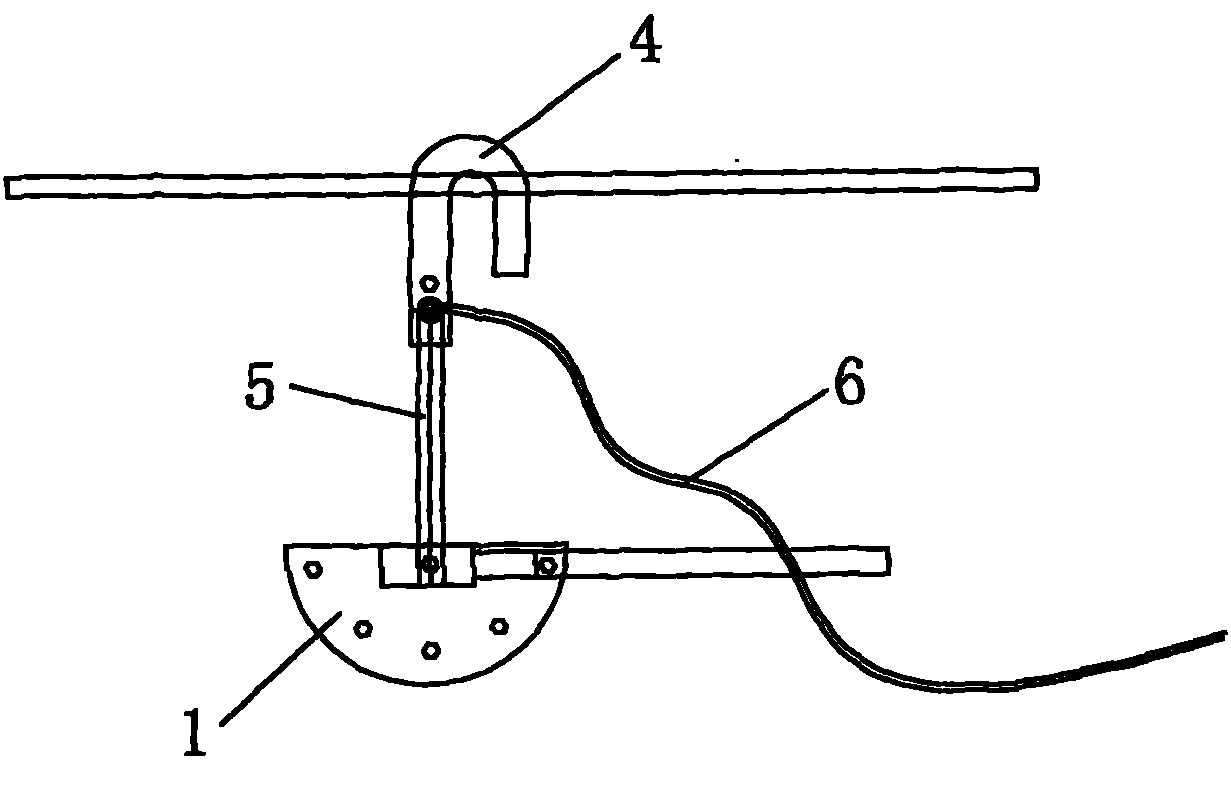

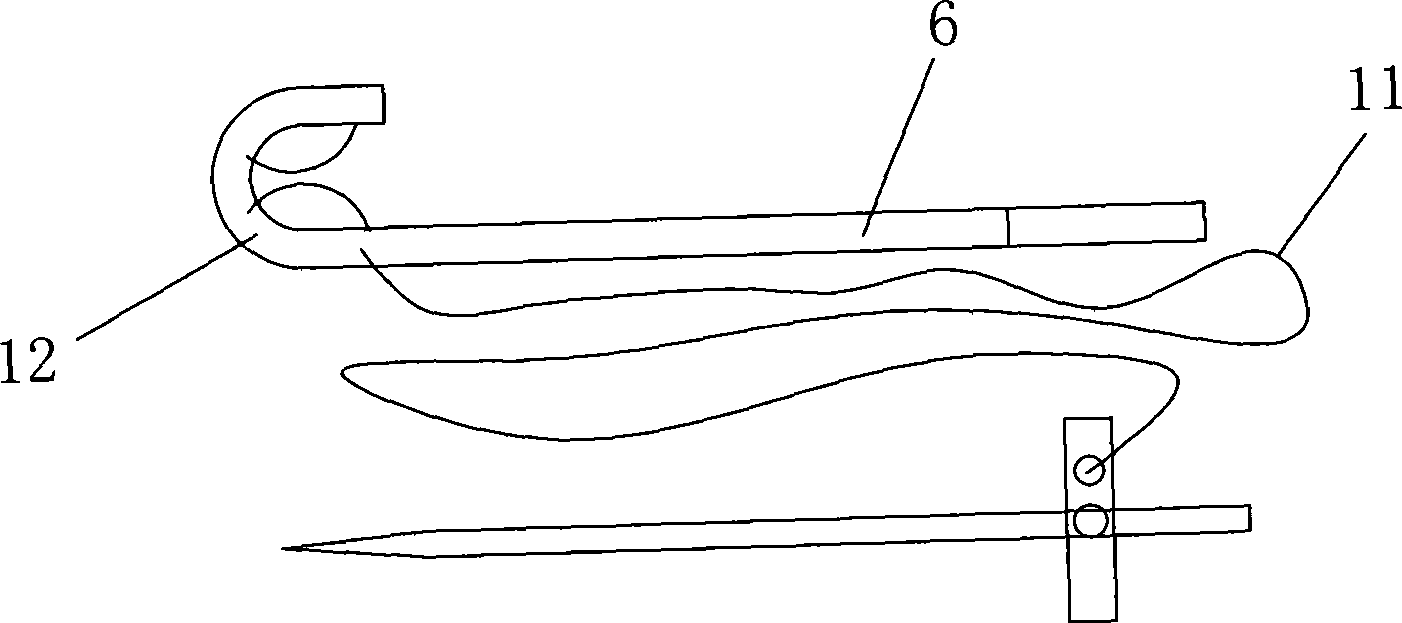

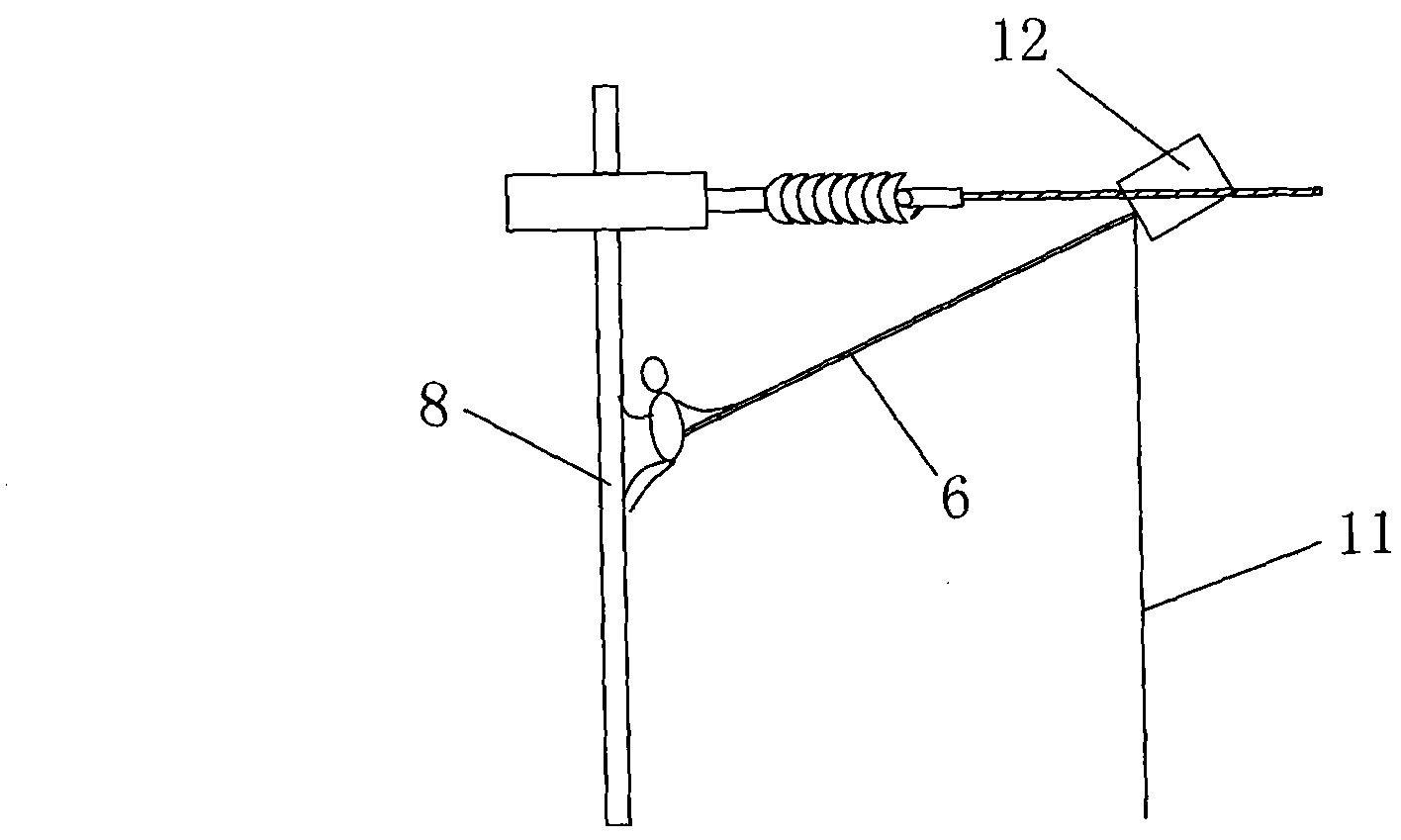

[0021] Referring to Fig. 4 and Fig. 5, a semicircular steering wheel 1 is set, and the semicircular steering wheel 1 has a center hole 2 at the center of the circle and steering holes 3 at different angle positions on the circumference, and the straight rod 5 connected with the hook 4 is fixed. Linked to the central hole 2, the steering rod 7 connected to the operating rod 6 is hinged on the central hole 2 with its rod end, and fixed in the steering hole 3 with the adjustment hole at the corresponding position. A set angle of rotation is formed with the steering rod 7 .

[0022] Referring to Fig. 4 and Fig. 5, a semicircular steering wheel 1 is set, and the semicircular steering wheel 1 has a center hole 2 at the center of the circle and steering holes 3 at different angle positions on the circumference, and the straight rod 5 connected with the hook 4 is fixed. Linked to the steering wheel 1, the steering rod 7 connected with the operating rod 6 is hinged on the center hole 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com