Fountain solution filtering method and device for printing

A filtering method and dampening solution technology, which is applied in printing, printing machines, rotary printing machines, etc., can solve the problems of increasing chemical substances and waste, shortening the service life of dampening solution, and consuming a lot of time, so as to achieve the reduction of adjustment , prolong service life and reduce downtime

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

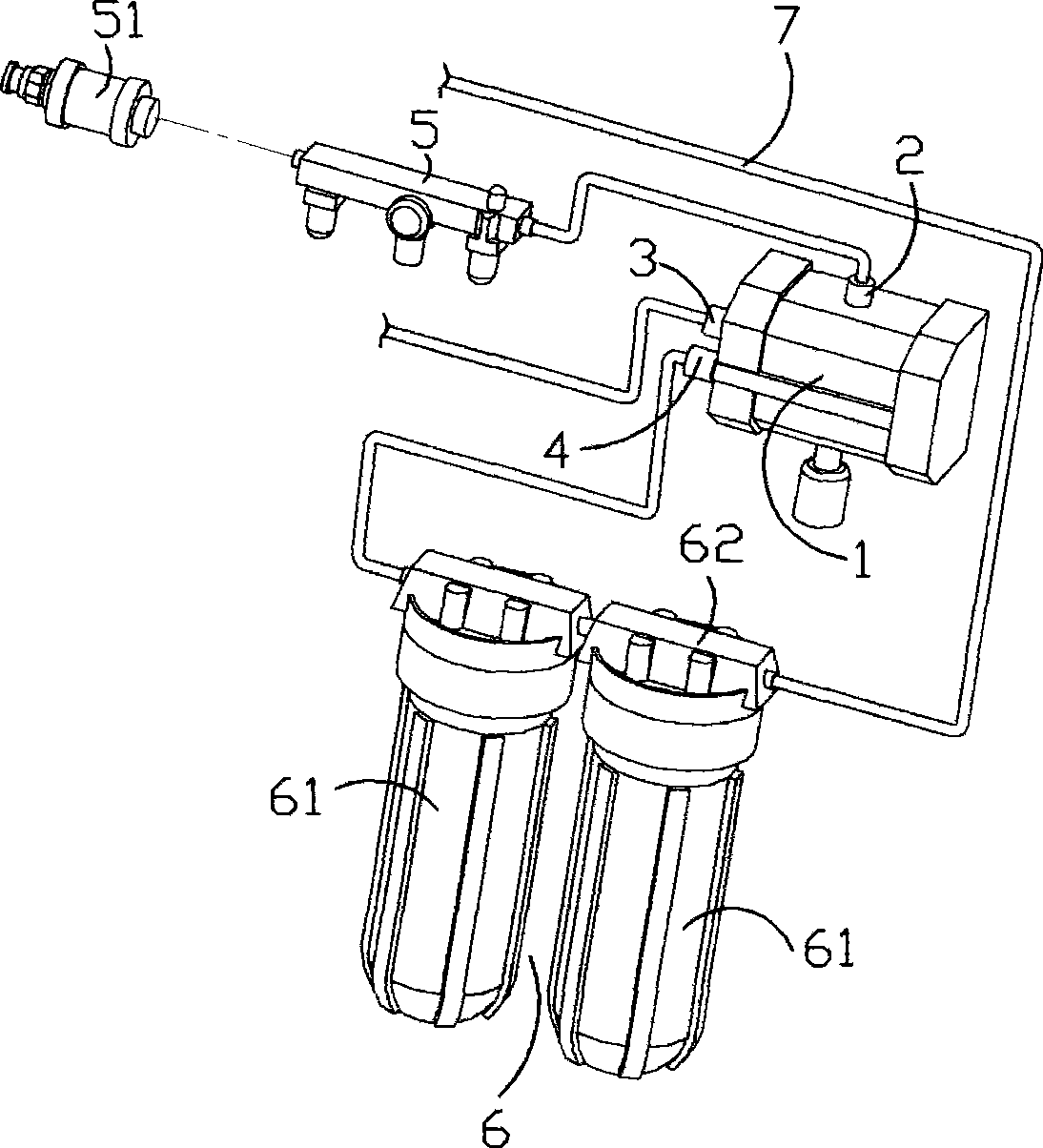

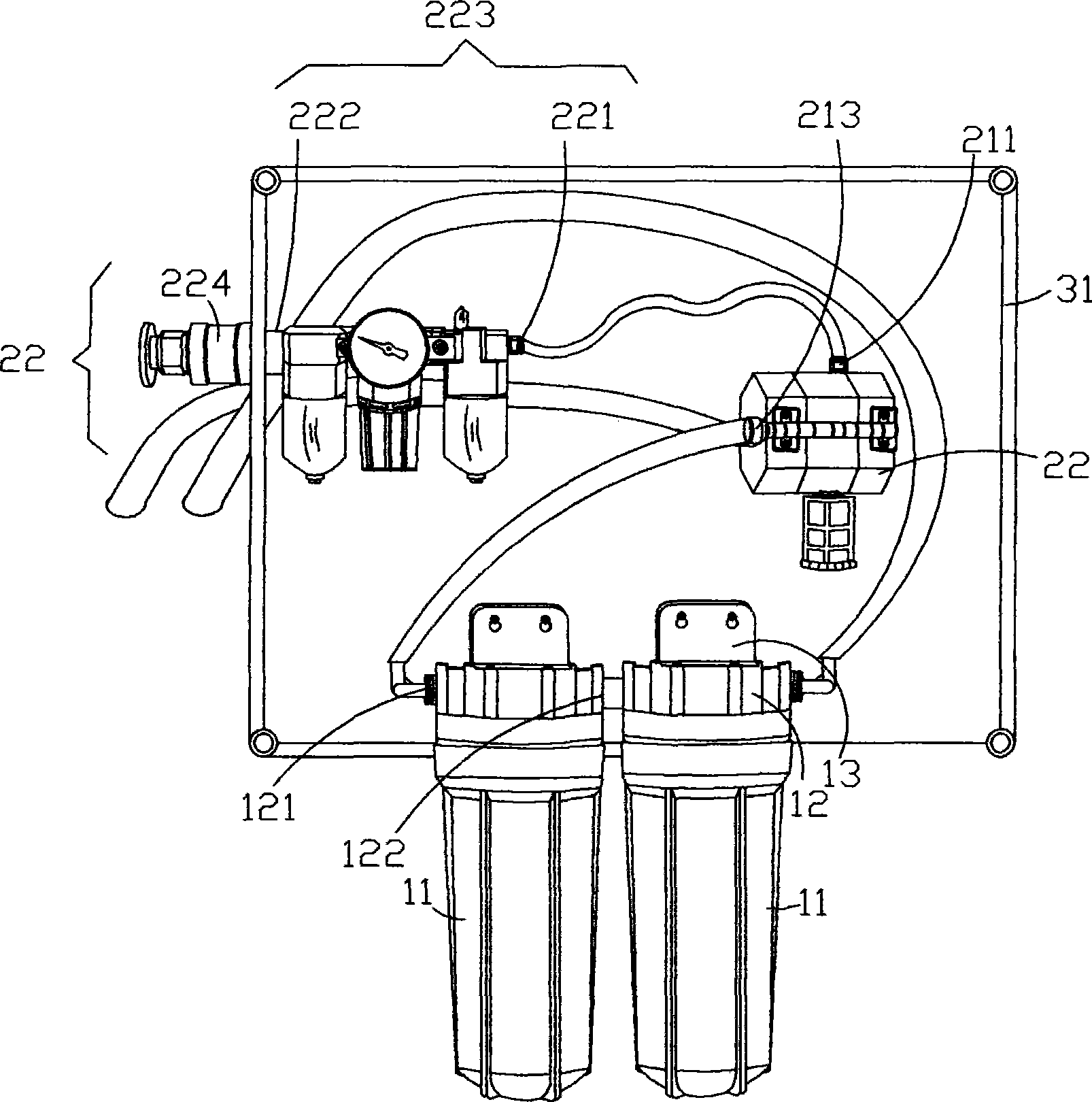

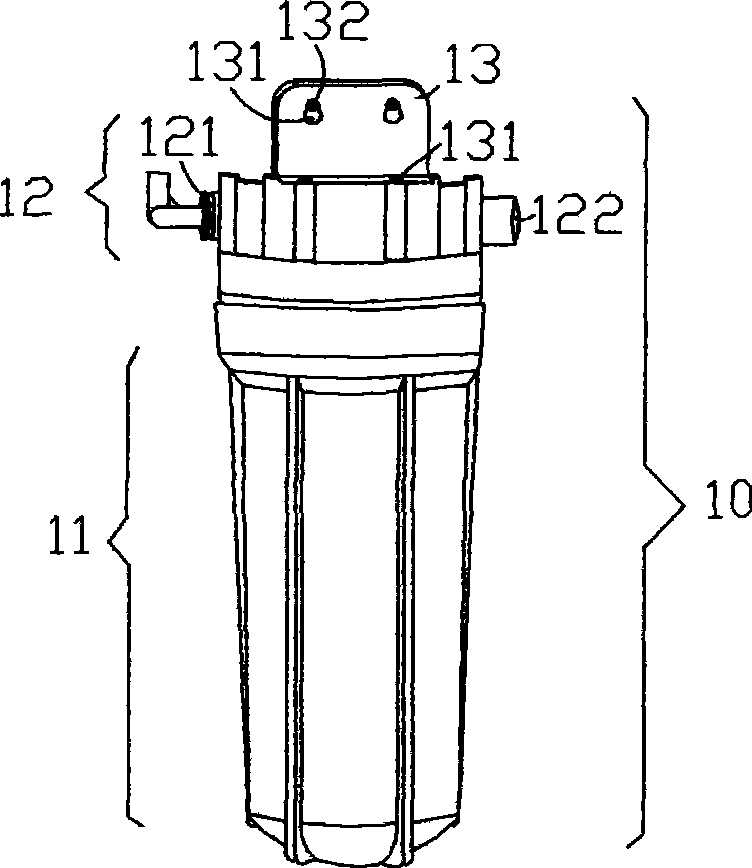

[0033] Such as Figures 1 to 7 Shown, a kind of fountain solution filtering method and device thereof for printing, wherein, such as figure 1 The printing fountain solution filtration method shown includes:

[0034] The first step is to suck the printing dampening solution from the external circulation loop of the dampening solution into a pneumatic dampening solution filtering device by using the pneumatic principle.

[0035] As mentioned above, sucking the dampening solution using the pneumatic principle is realized by means of the self-priming air-operated pump 1 , and the self-priming air-operated pump 1 has an air inlet 2 , a liquid inlet 3 and a liquid outlet 4 .

[0036] Wherein, the air inlet 2 is connected with the air pressure control gauge 5, and the air pressure control gauge 5 is connected with the external air hole 51, and the liquid inlet 3 is connected with the external circulation circuit of the dampening solution.

[0037] In the second step, the dampening ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com