Self-discharging vehicle chassis assembly without sub frame

A technology for dump trucks and sub-frames, which is applied to vehicle components, substructure, transportation and packaging, etc. It can solve the problems of poor adaptability, large curb weight, and high center of gravity of the vehicle, and achieve low matching center of gravity, mature and reliable technology , high reliability effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

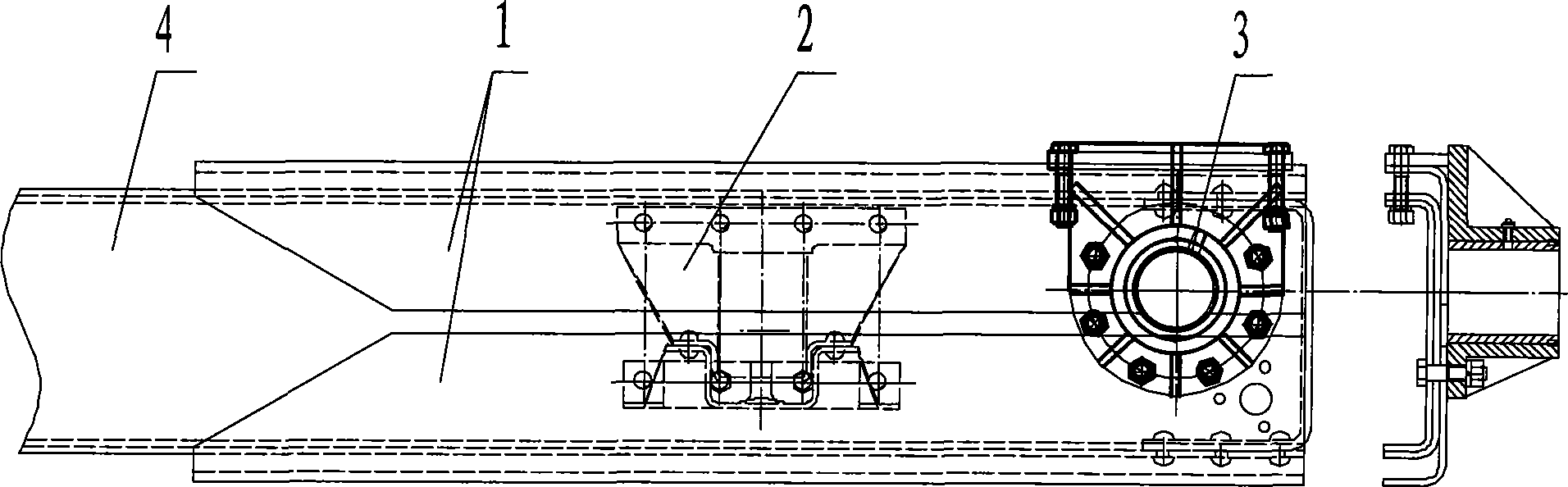

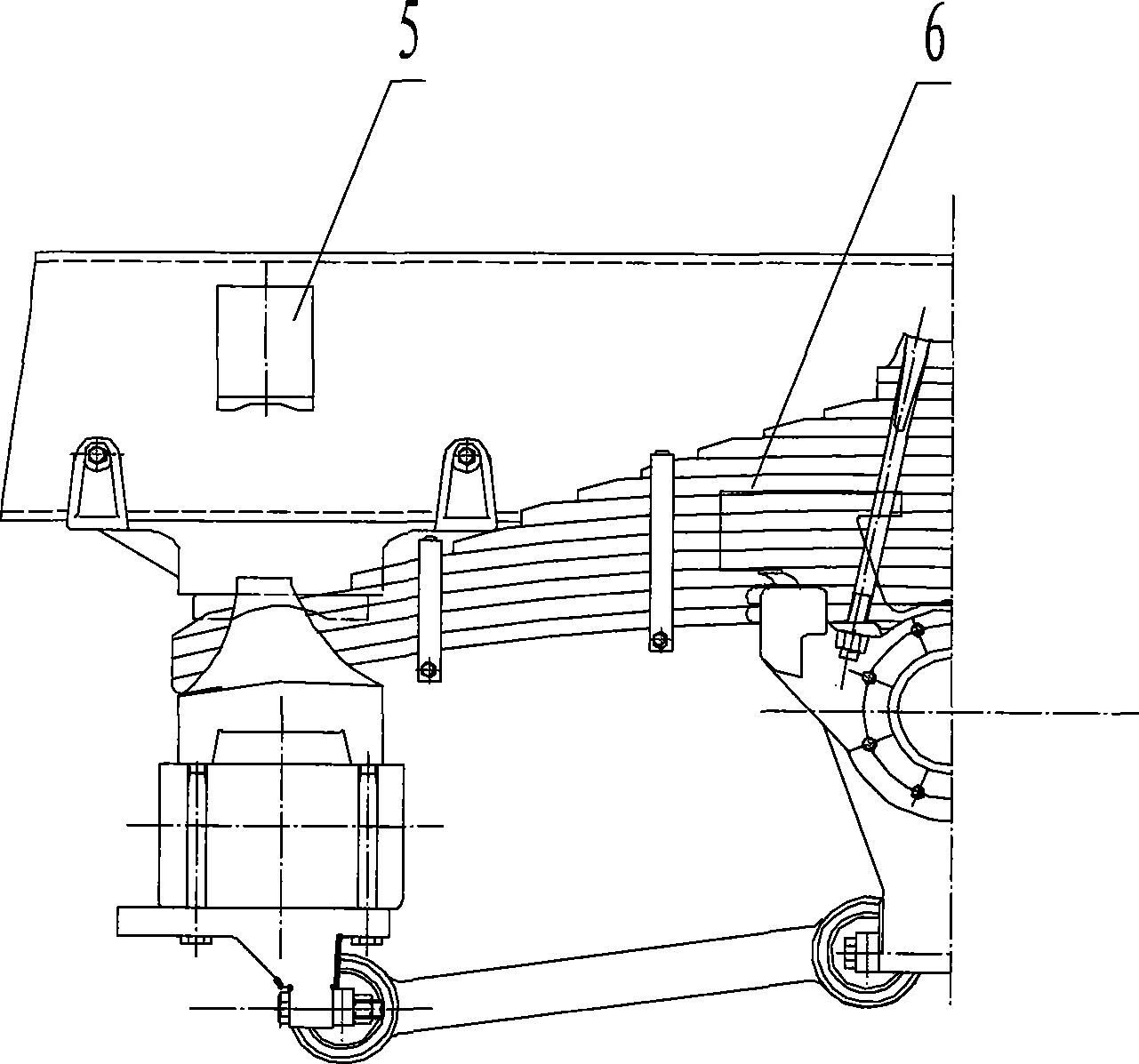

[0010] Such as figure 1 as shown, figure 1 Add upper and lower L-shaped reinforcement beams 1 to the longitudinal beam 4 of the chassis body and lengthen to the tail end of the longitudinal beam 4; add a crossbeam 2 at the tail near the chassis body to connect with the longitudinal beam 4 of the chassis body on the abdomen; The afterbody of the longitudinal beam 4 of the chassis body is equipped with an overturning shaft holder 3, and the through shaft centerline of the overturning shaft holder is perpendicular to the longitudinal beam 4 of the chassis body. Such as figure 2 As shown, a side limiting block 5 is provided on one side of the longitudinal beam 4 of the chassis body, and on the upper front of the installation position of the leaf spring 6 . The side limit block 5 is installed in the middle, which improves the operation stability. In the dump truck without subframe of the present invention, the turning device is fixed on the turning shaft fixing seat of the chas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com