Thread cutting apparatus for sewing machine

A sewing machine and thread trimming technology, which is applied to the sewing machine control device, sewing machine components, and thread cutting mechanism in the sewing machine, etc., can solve the problems such as the broken shape of the upper thread loop, the failure of the thread catching part to protrude and rise, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

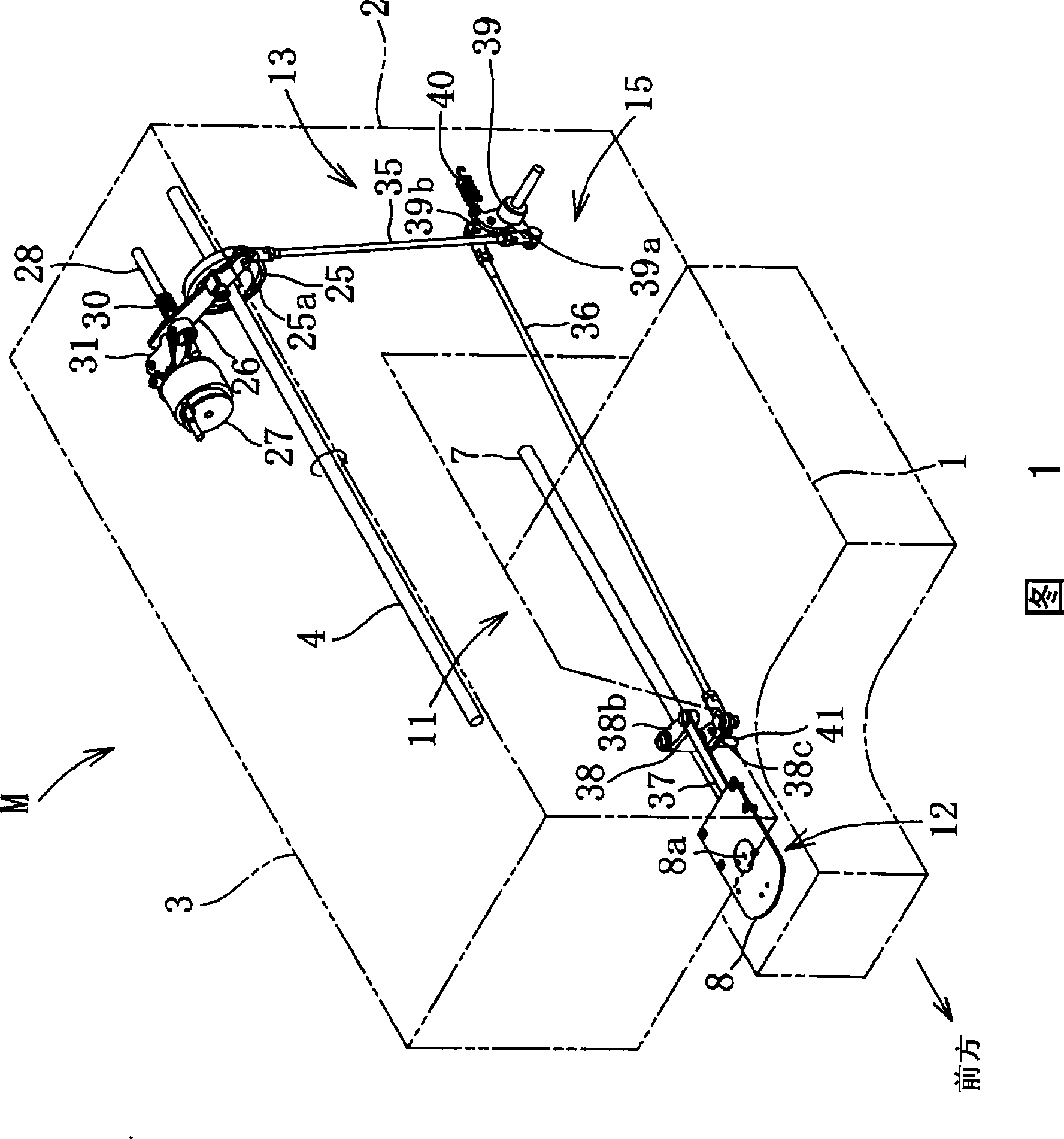

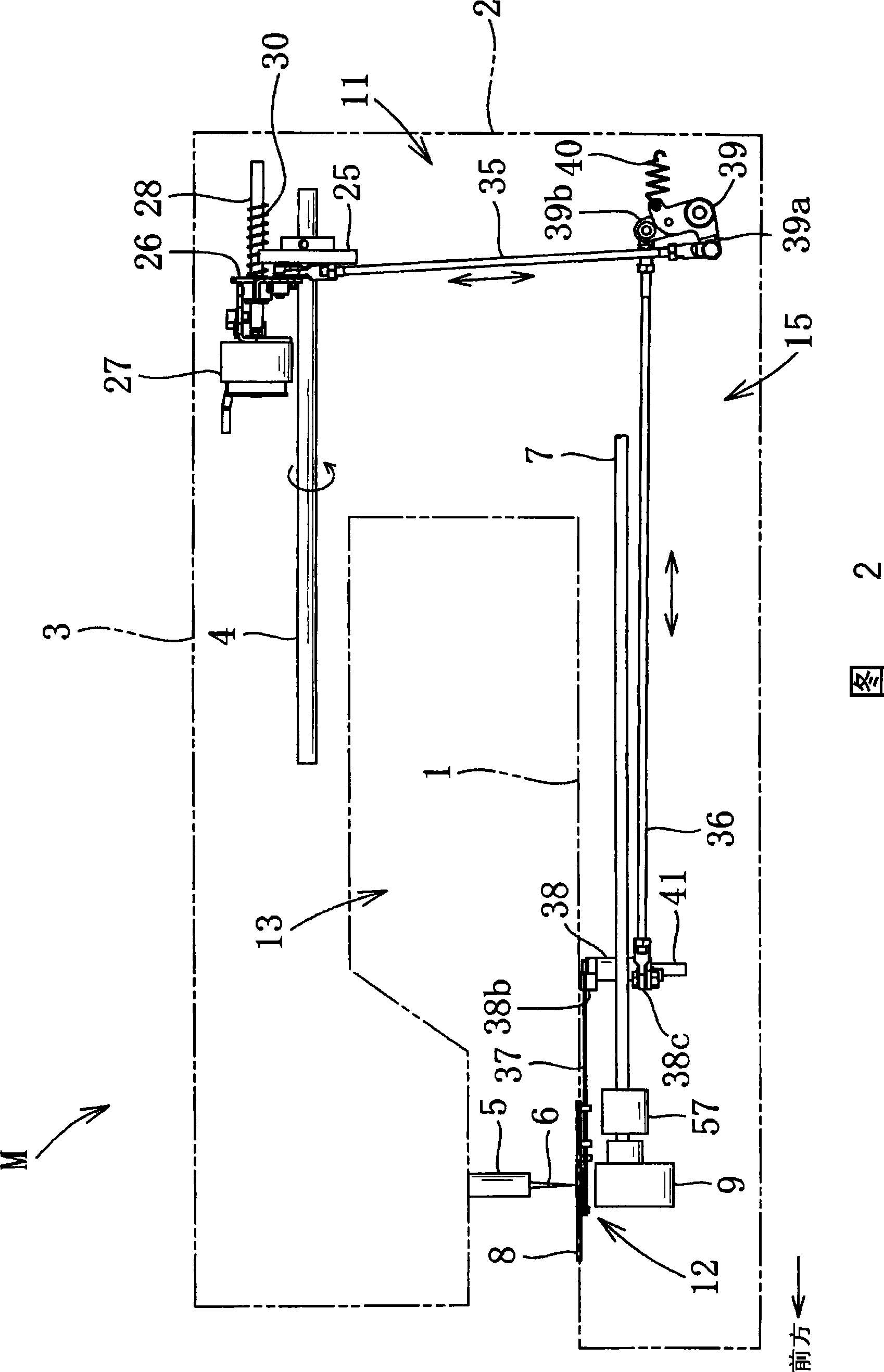

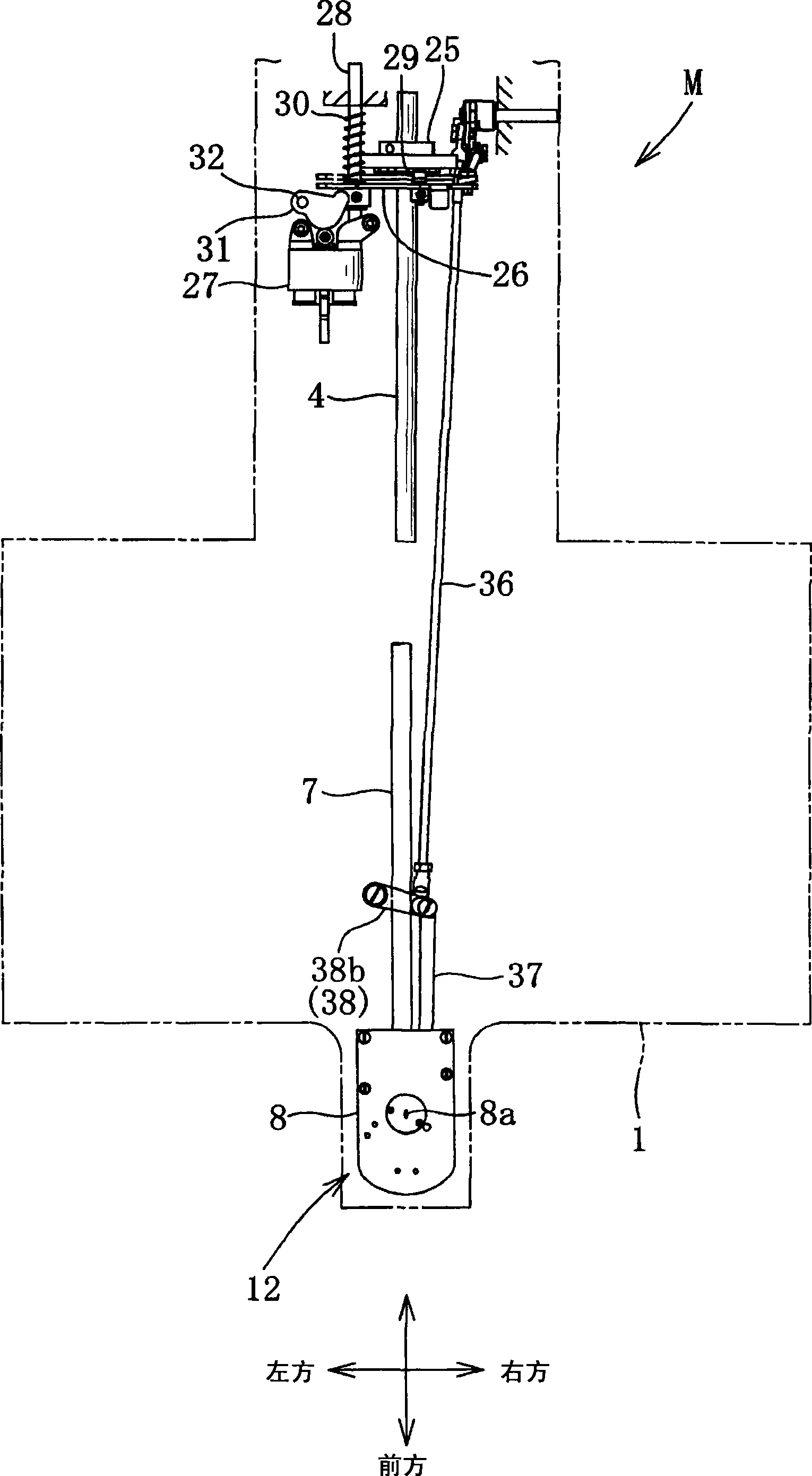

[0048] The present invention will be described in detail below with reference to the drawings showing preferred embodiments.

[0049] Figure 1~ Figure 4 As shown, the sewing machine M includes a bottom plate 1 , a column 2 and a machine arm 3 . A needle plate 8 is detachably mounted on the front portion of the base plate 1 . Column 2 erects upwards from the rear upper surface of base plate 1 . The arm 3 extends forward from the upper end of the column 2 so as to face the bottom plate 1 .

[0050] The arm 3 has inside it a sewing machine main shaft 4 extending in the front-rear direction. The sewing machine main shaft 4 is rotated by transmission from a not-shown sewing machine motor. The sewing machine main shaft 4 drives a needle bar drive mechanism and a thread take-up drive mechanism provided on the front inner side of the machine arm 3 . The needle bar driving mechanism drives the needle bar 5 (see FIG. 2 ) in the vertical direction. The thread take-up drive mechani...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com