Fastening tubular scaffold falsework

A technology of scaffolding and steel pipes, which is applied to the preparation of formwork/formwork/work frames, building components on site, construction, etc., and can solve problems such as lack of accurate design regulations, no series of erection structure dimensions, and potential safety hazards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

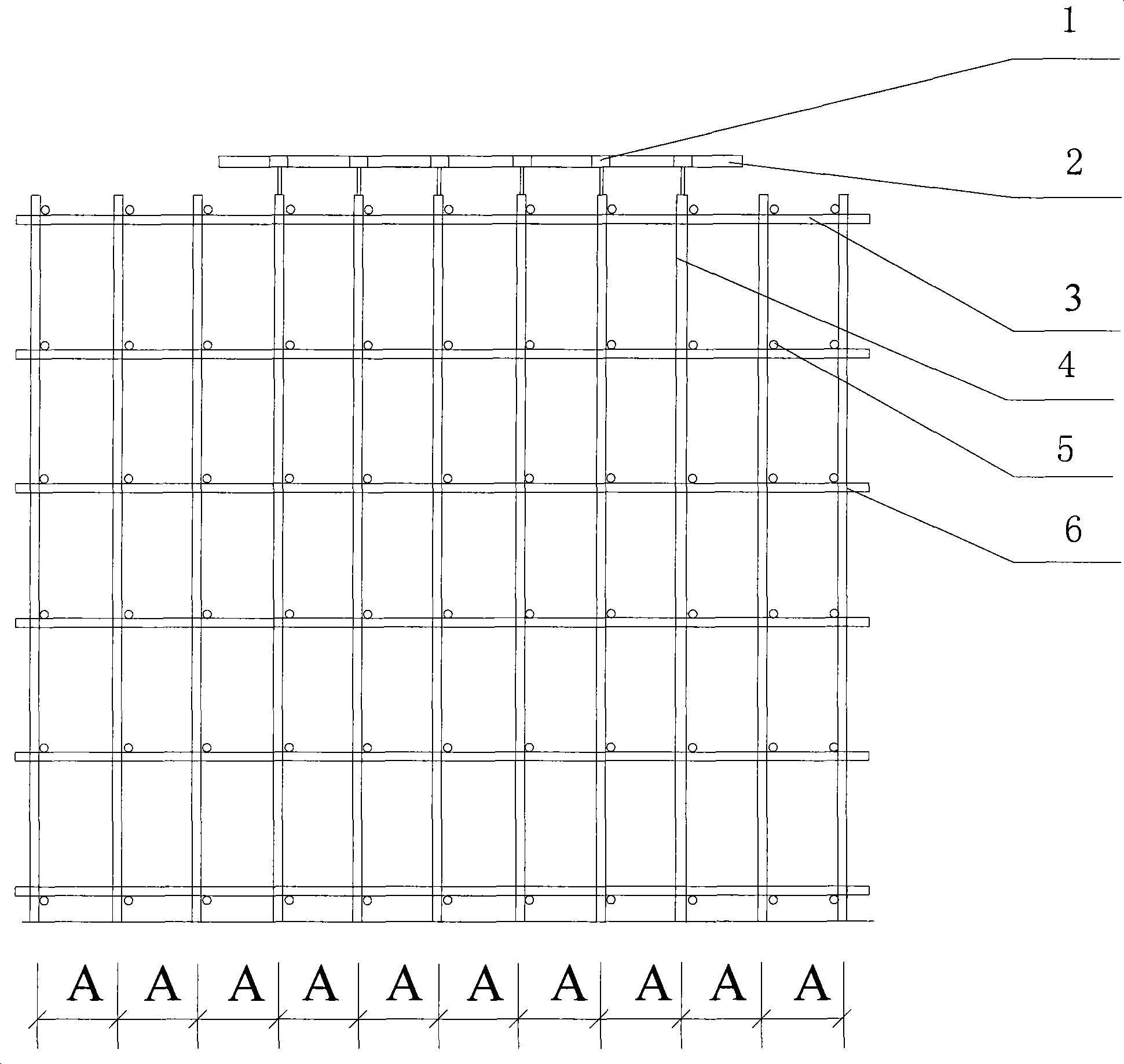

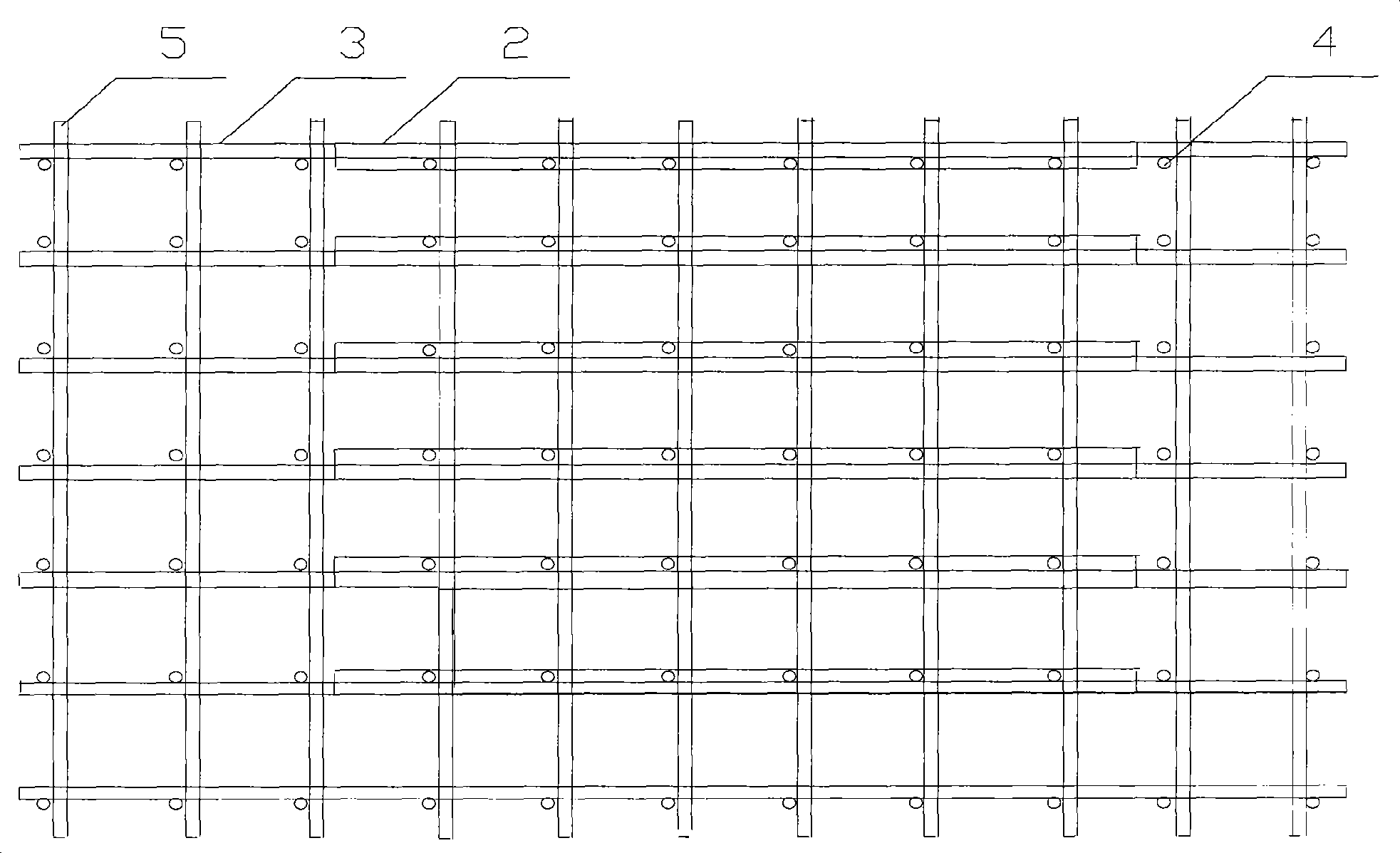

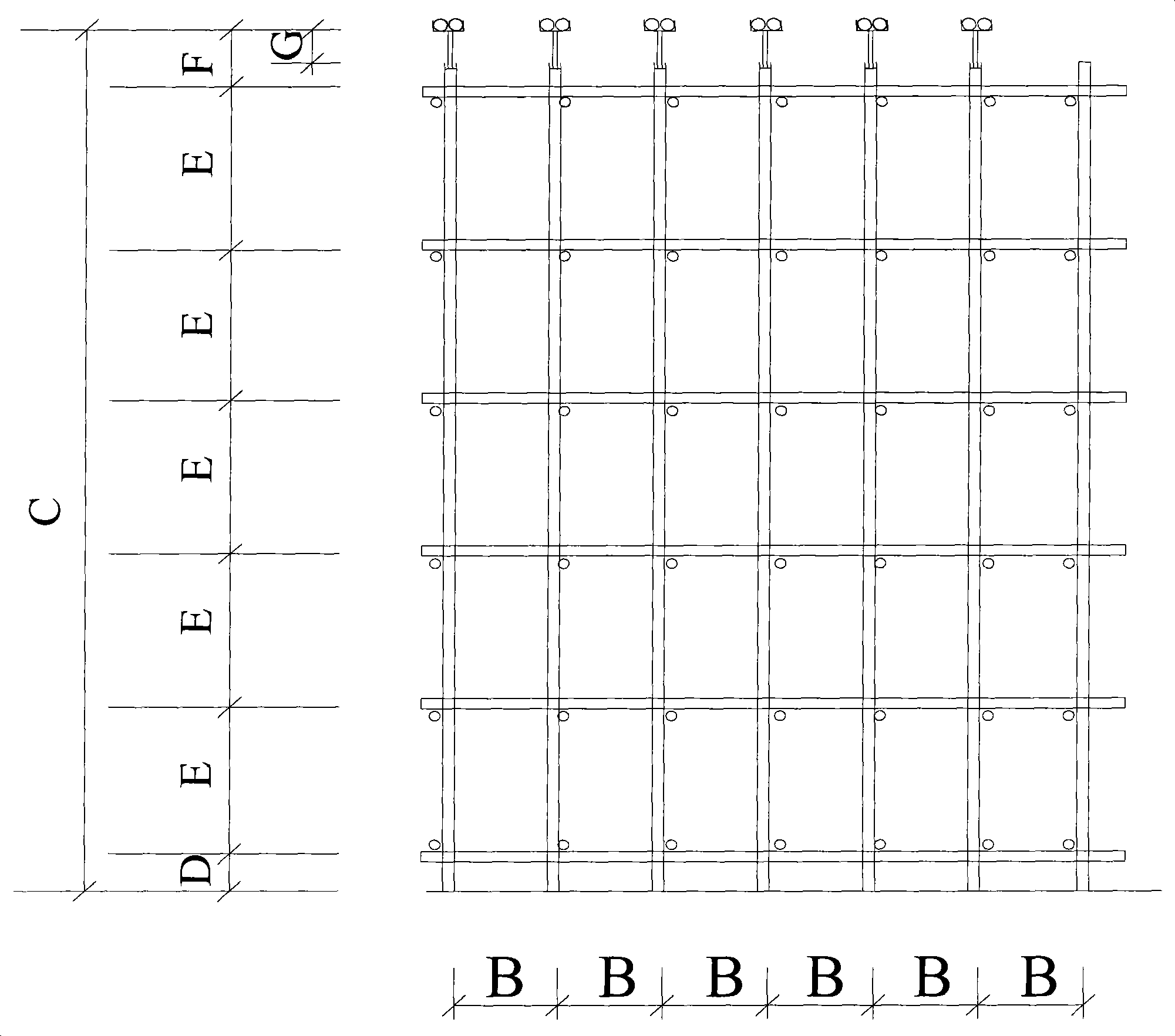

[0016] A fastener-type steel pipe scaffold formwork support, including a vertical steel pipe 4, a longitudinal horizontal rod 3 and a horizontal horizontal rod 5; the nodes are connected by malleable cast iron fasteners 6, and the upper part of the bracket is supported by an adjustable bracket 1 Φ48×3.5 double steel pipes 2 As the main beam of the support formwork, the bottom of the adjustable bracket 1 is inserted into the steel pipe 4 of the support vertical rod and fixed. The support has 10 spans in the vertical direction and 6 spans in the horizontal direction, loaded within the range of 5 spans × 5 spans, with 2 spans on one longitudinal side outside the loading area and 3 spans on the other side; 1 span on the lateral side outside the loading area, and no additional spans on the other side; The aspect ratio of the support=8.15÷(6×0.94)=1.44; the aspect ratio of the loading area of the support=8.15÷(5×0.94)=1.73; the sweeping pole is the lower crossbar of the support, an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Horizontal spacing | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com