Display apparatus assembly construction and method

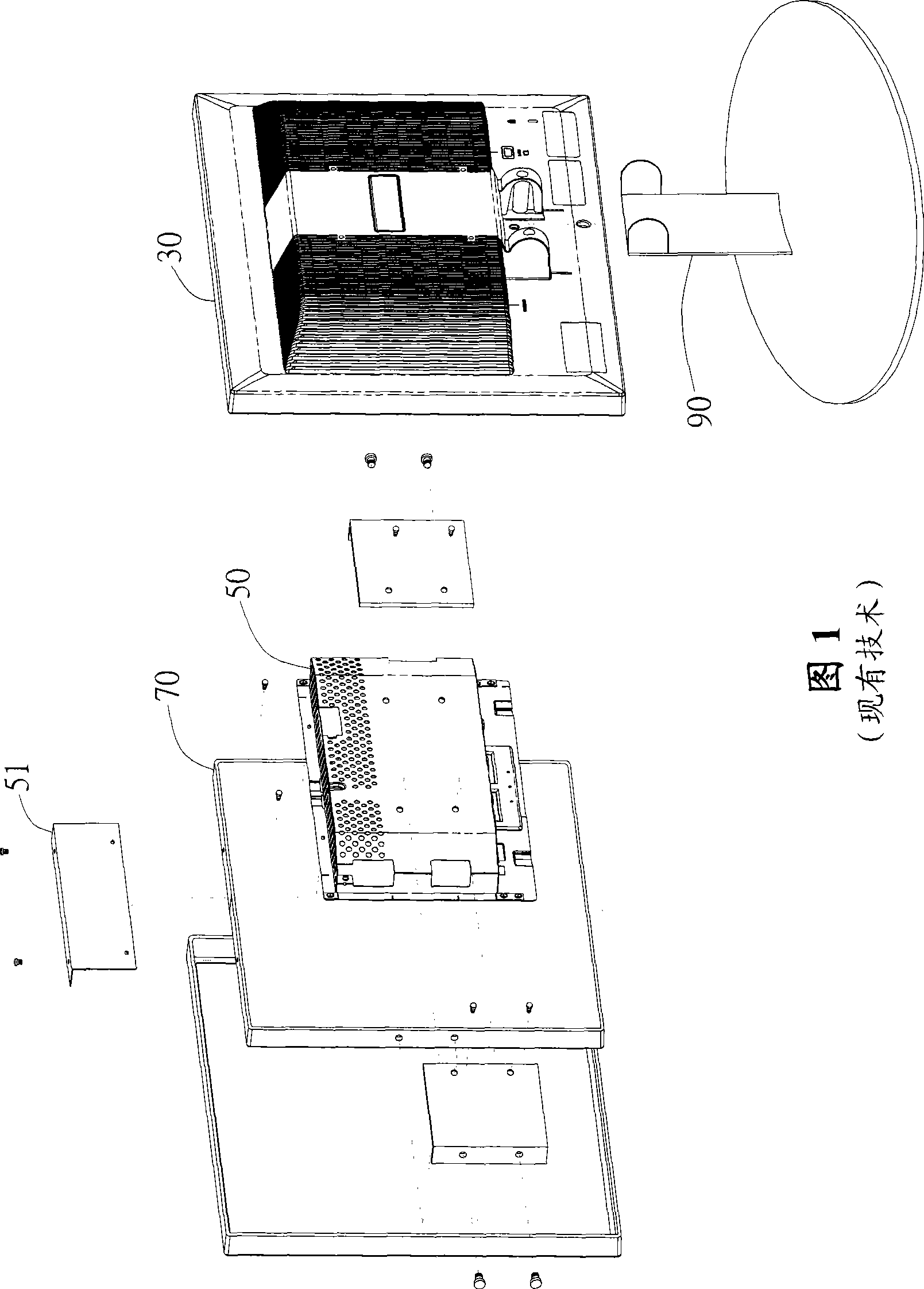

A technology for display devices and assembly structures, applied to identification devices, electrical equipment components, instruments, etc., can solve the problems of increasing the load of the support frame 90, reducing the stability of the display device 10, and increasing the assembly cost of the display device 10

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

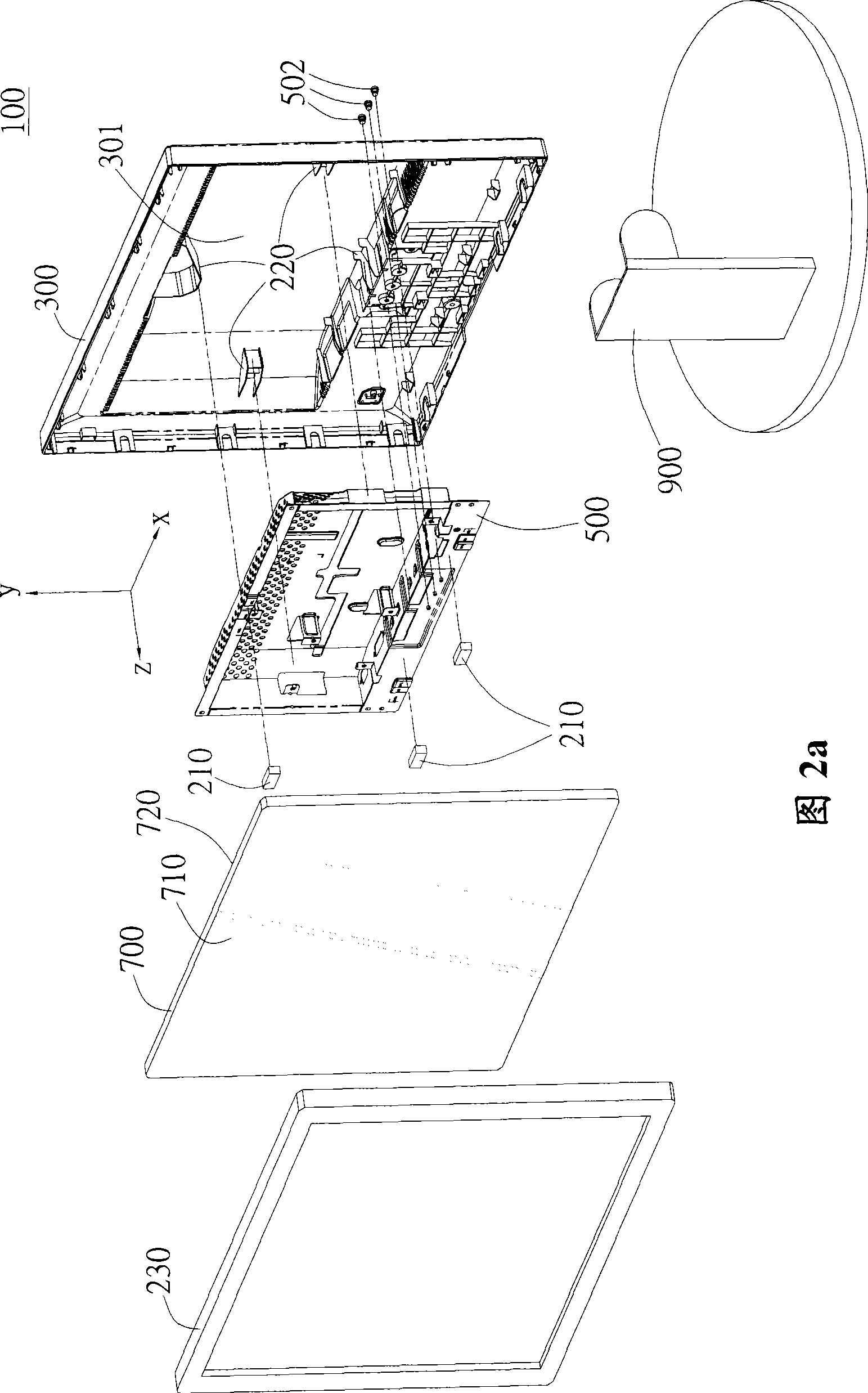

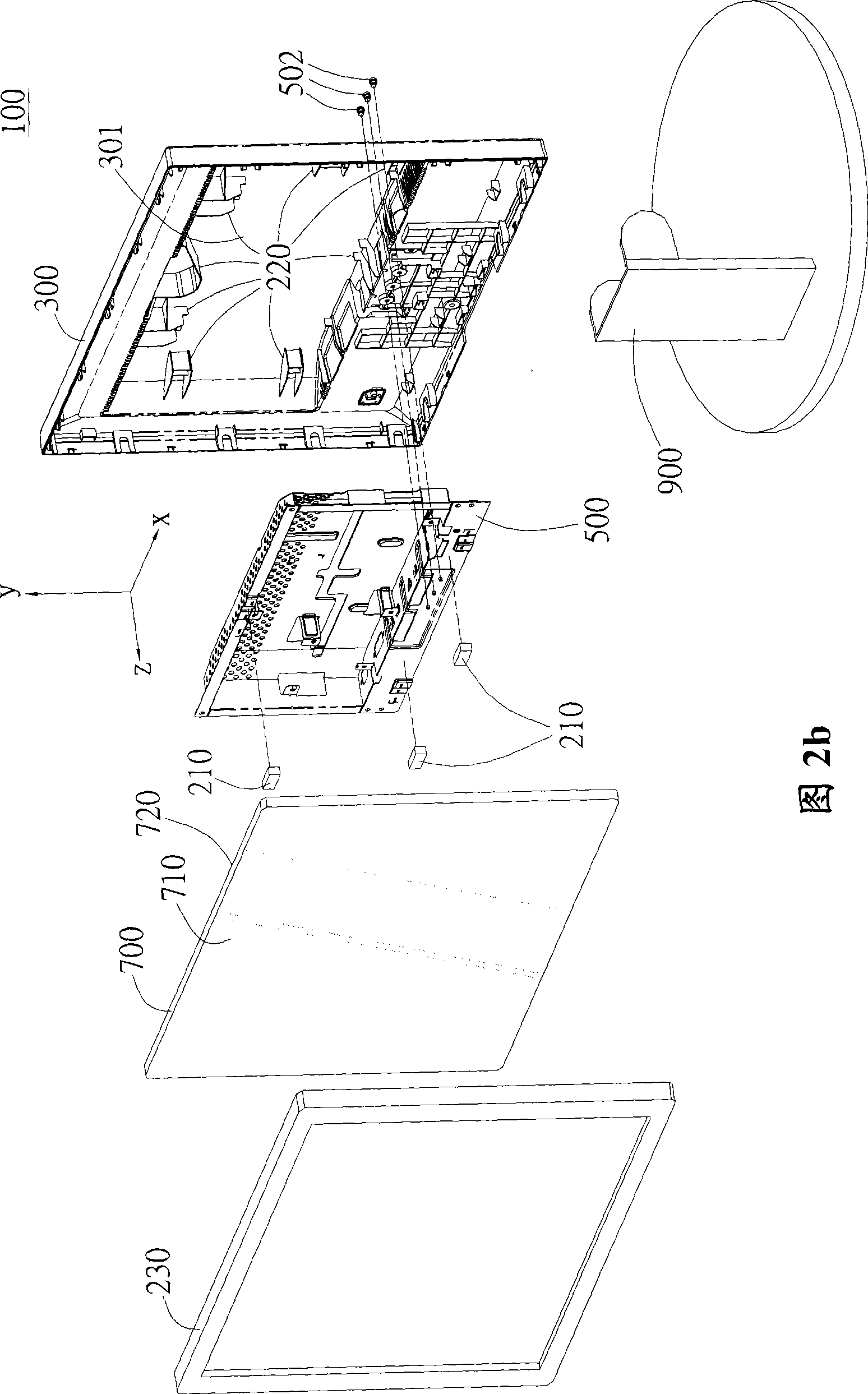

[0026] The invention provides an assembly structure of a display device. In a preferred embodiment, the display device may comprise a liquid crystal display; however, it may also be an organic light emitting diode display, a liquid crystal television, an organic light emitting diode television, and other devices with similar display functions.

[0027] As shown in the exploded view of the preferred embodiment in FIG. 2 a , the display device assembly structure 100 includes a panel module 700 , a protective metal part 500 , a first displacement limiting device 210 , and a rear case 300 . In the preferred embodiment shown in FIG. 2a, the panel module 700 is a liquid crystal display panel module; however, in other embodiments, the panel module 700 can also be an OLED panel or other thin display device panels. The panel module 700 has a display surface 710 for displaying images; the protective metal part 500 is disposed on the back surface 720 of the panel module 700 opposite to t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com