Anchoring devices for rail fastening clips

An anchoring device and fastener technology are applied in the field of anchoring devices for rail fastening fasteners, and can solve the problems of inaccessibility and hard grinding.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

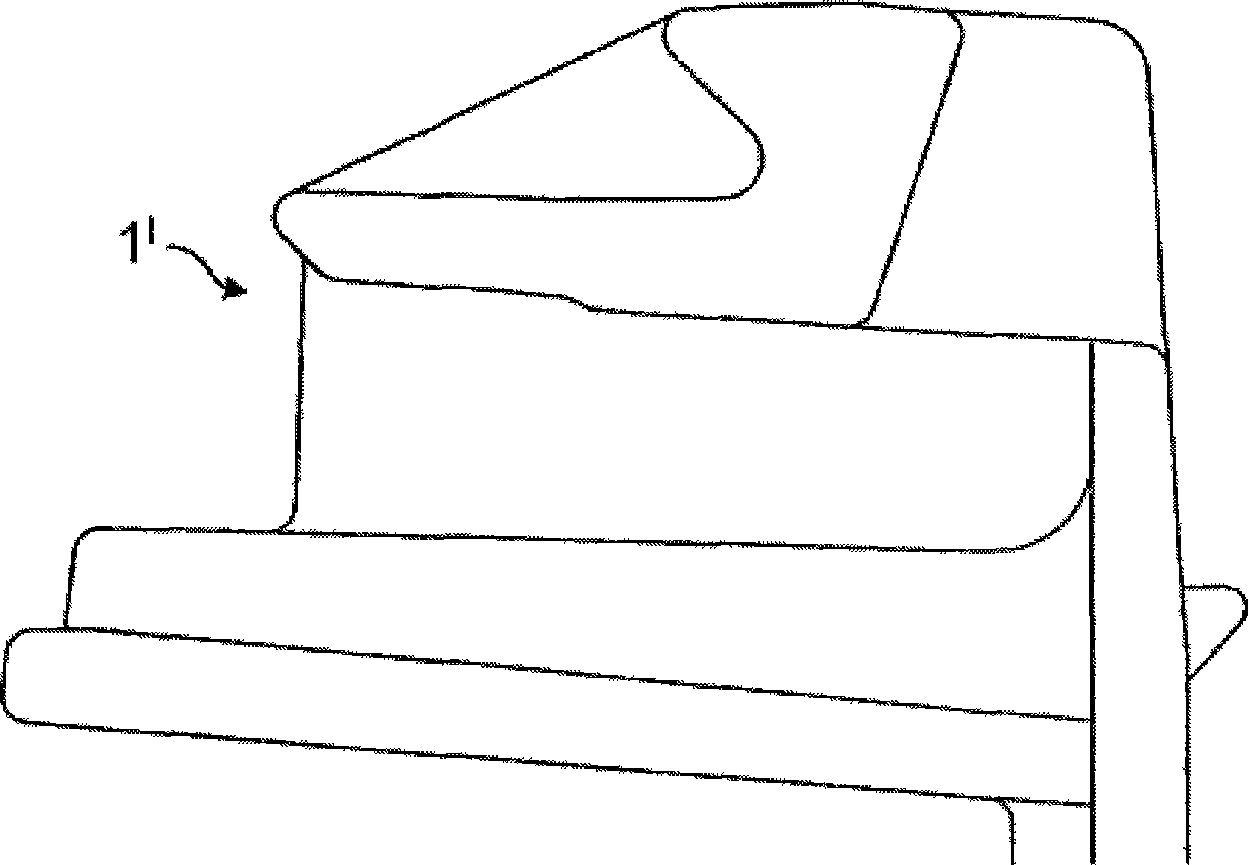

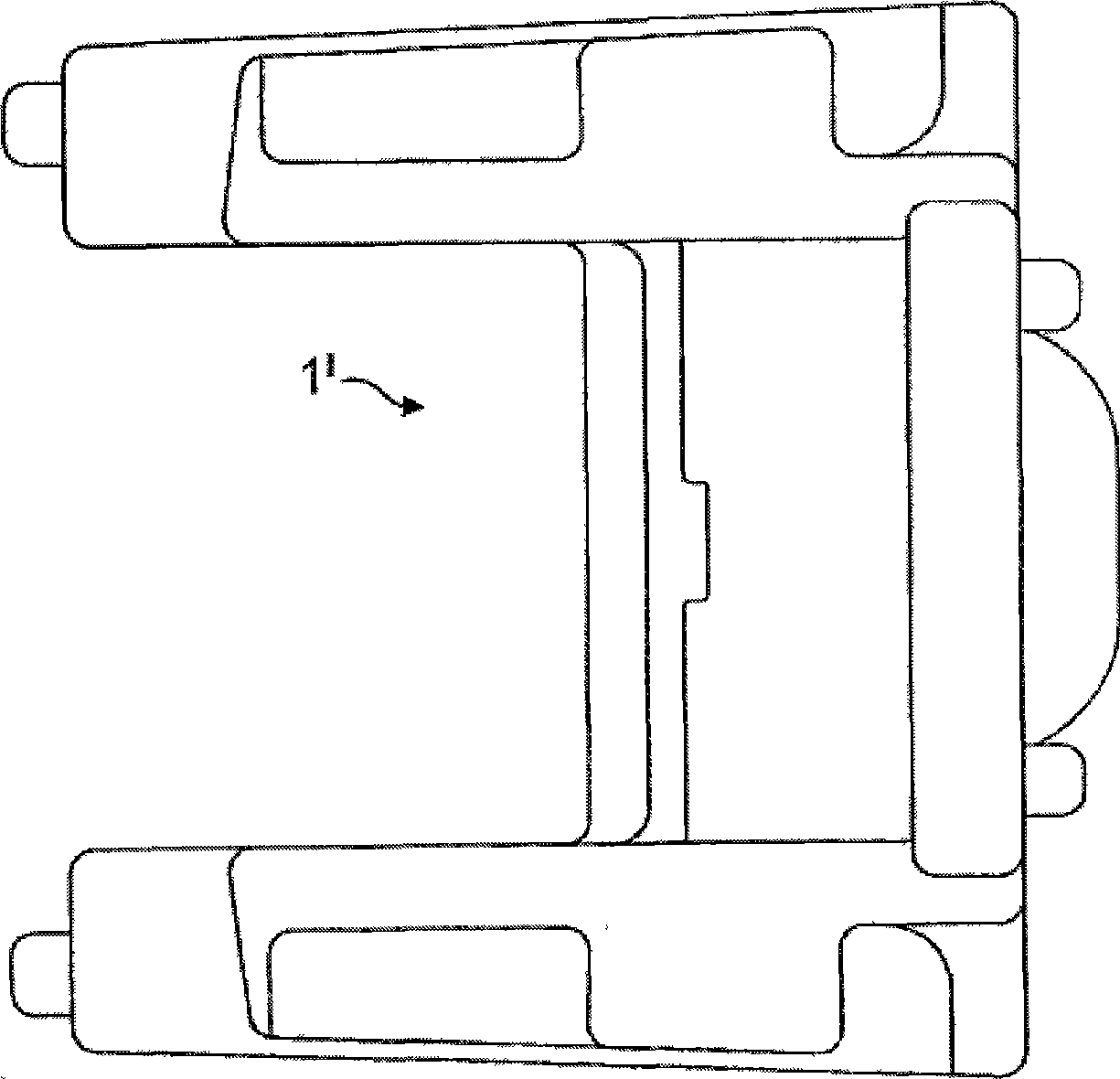

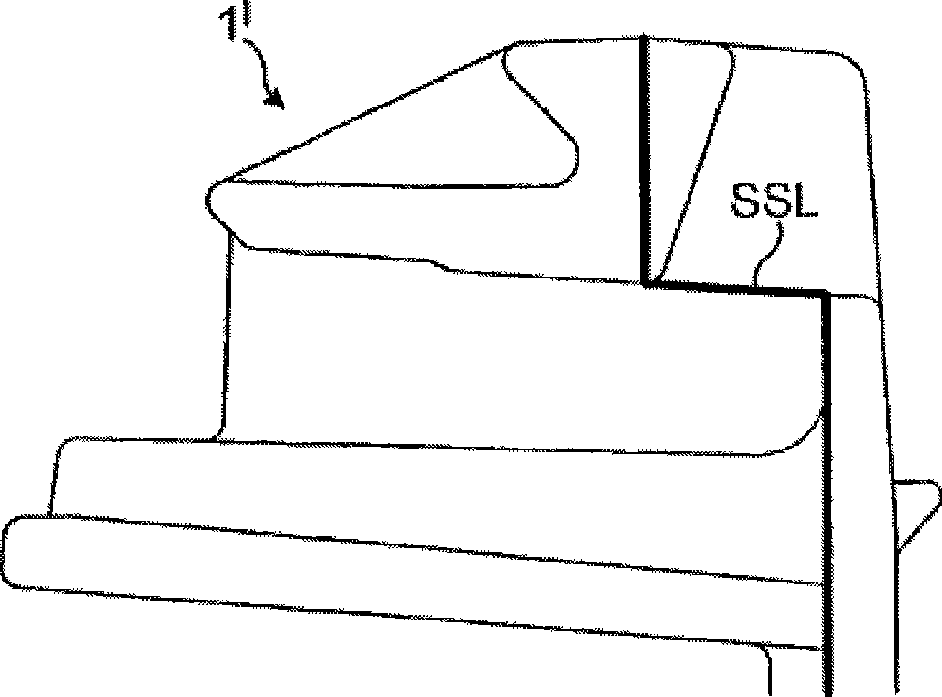

[0030] Figures 5A to 5G An anchoring device (shoulder) embodying the first to third aspects of the invention is shown. Figures 5A to 5G The anchoring device shown comprises a head 1A, a stem portion 1B projecting downwardly from the bottom side of the head 1A, and two mutually spaced apart feet 1C. The stem portion 1B comprises a generally Y-shaped stem 100 connected to the underside of the head 1A at the end of a Y-shaped upper arm 101, and a bend 102. Located at the other end of the Y for preventing the stem from backing out of the concrete into which it is inserted when said stem is in use. Figure 5H shows another embodiment of an anchoring device embodying the first to third aspects of the present invention, wherein one or more nets 1D are provided on the bottom side of said anchoring device 1, the nets 1D will The stem 100 of the anchoring device 1 is connected to the head 1A, and the mesh 1D is used to replace or assist the foot (not shown in FIG. 5H ) when the faste...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com