Non-inflating cavity type tyre

An air-free and tire-free technology, which is applied to non-pneumatic tires, tire parts, transportation and packaging, etc., can solve the problems of delay time, heavy curved spring tires, burst tires or run flat, etc. The effect of less work and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

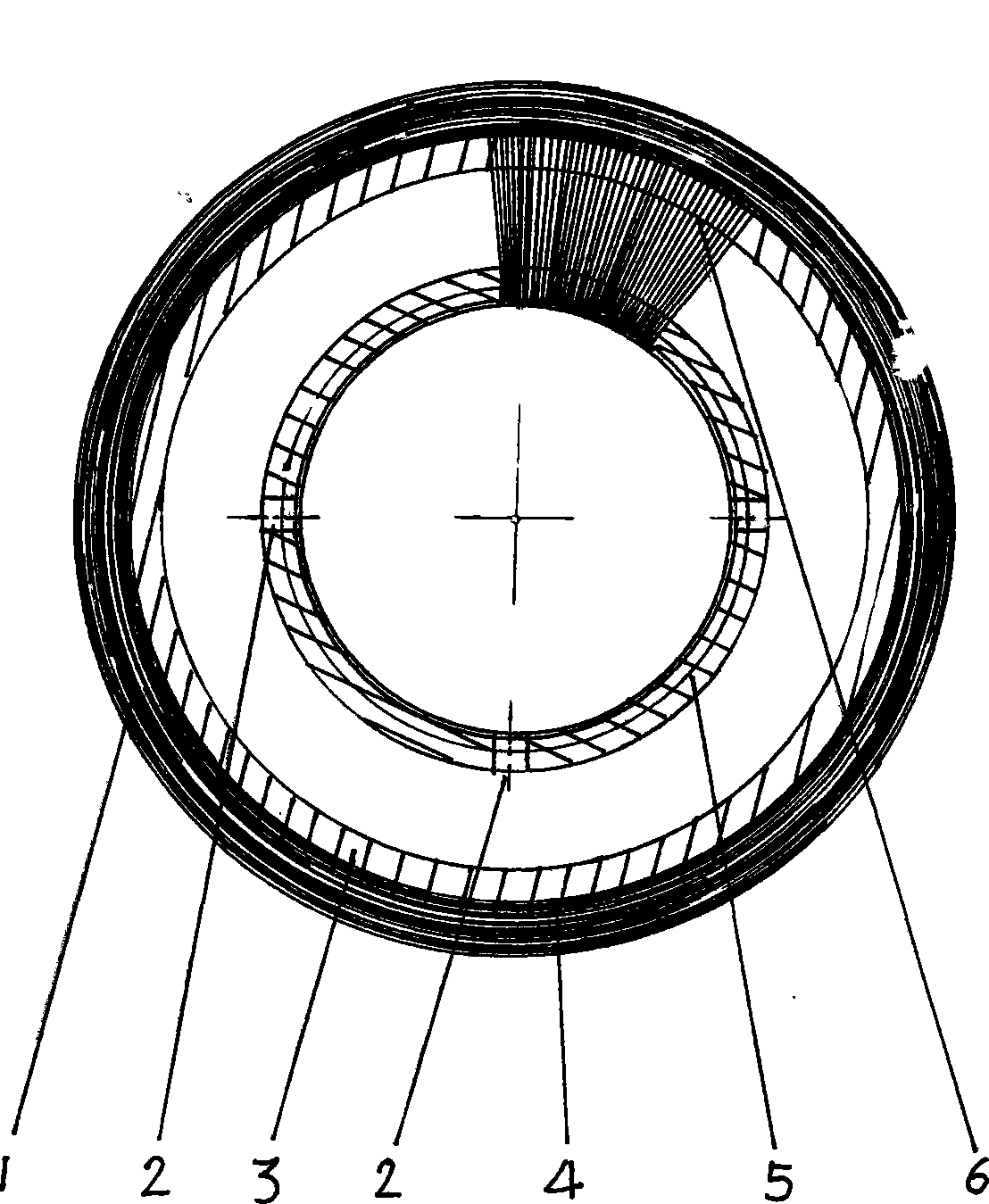

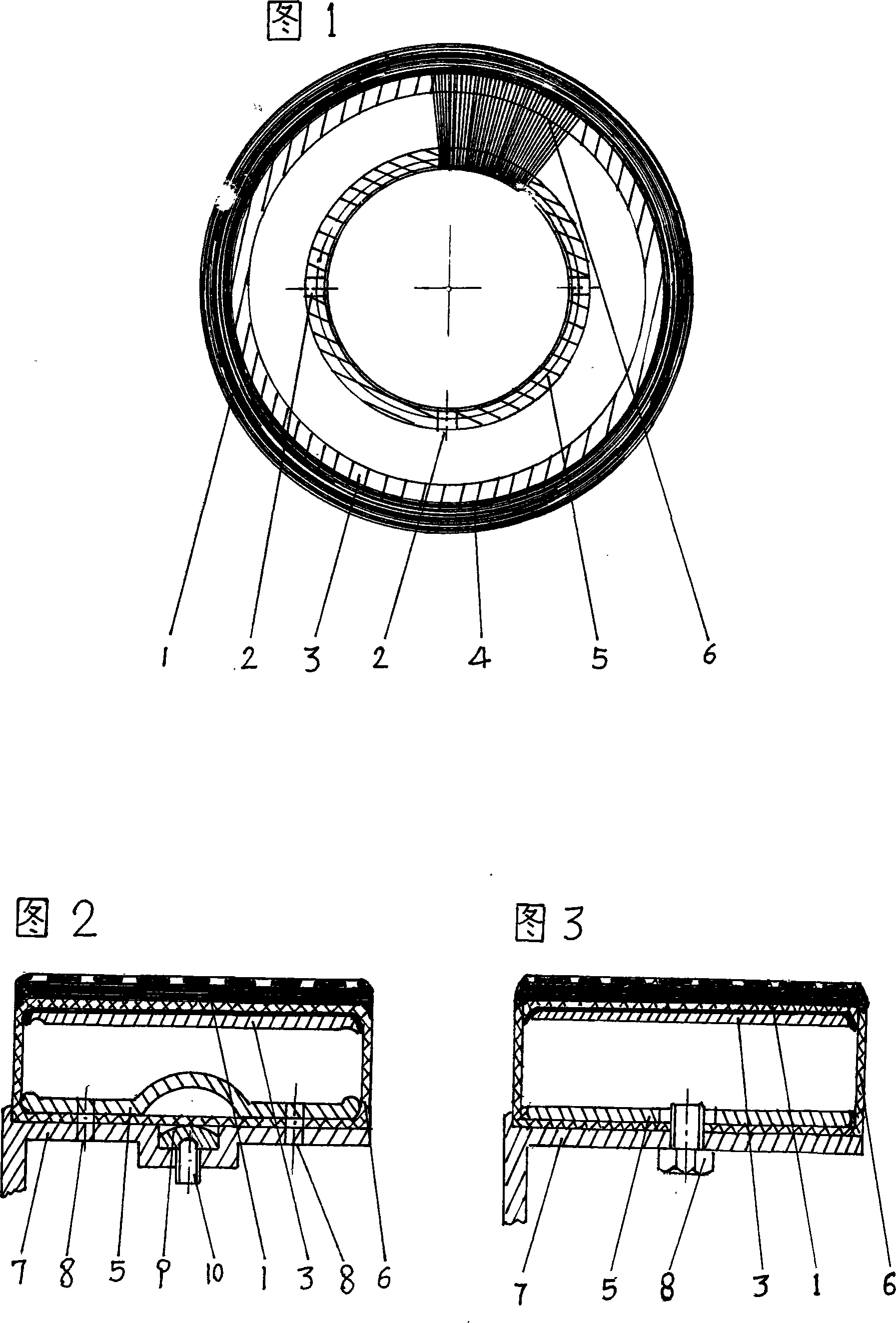

[0011] In Fig. 1, the outer surface of the annular elastic outer steel ring (3) is bonded with a layer of rubber as a buffer layer (4). The inner steel ring (5) is welded with the assembly nut (2) and the cord cord (6) to wrap the annular elastic outer steel ring (3) and the inner steel ring (5) into one body, and the equidistant space between the two steel rings, A cavity is naturally formed. The annular elastic outer steel ring (3) is subjected to the centripetal tension of the left and right sidewall cord cords (6), and the annular elastic outer steel ring (3) forms an elastic circular bow. Round bow, when there is no external force centripetal action, the annular elastic outer steel ring only has its own circular bow tension on the entire tire cord cord (6) The tensile fatigue force is very small, only when the tire part is under centripetal pressure, the cord cord Only then will the corresponding resistance pull force be produced. Tension and tension support each other ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com