Staged air drying device for food drier

A technology of food drying and air-drying device, which is applied in the fields of food preservation, application, food science, etc., can solve the problems of ineffective drying of water, weakened wind, and poor air-drying effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

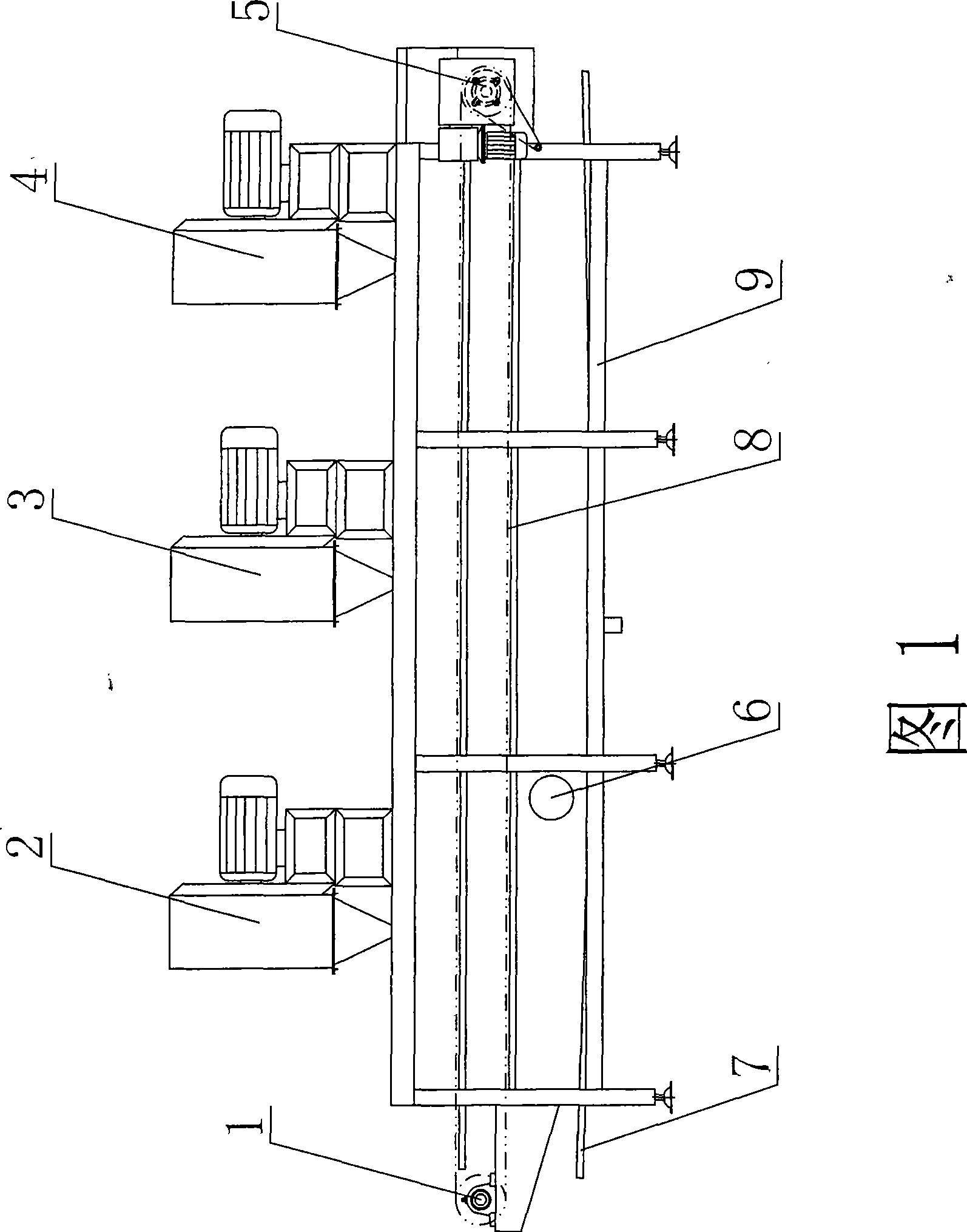

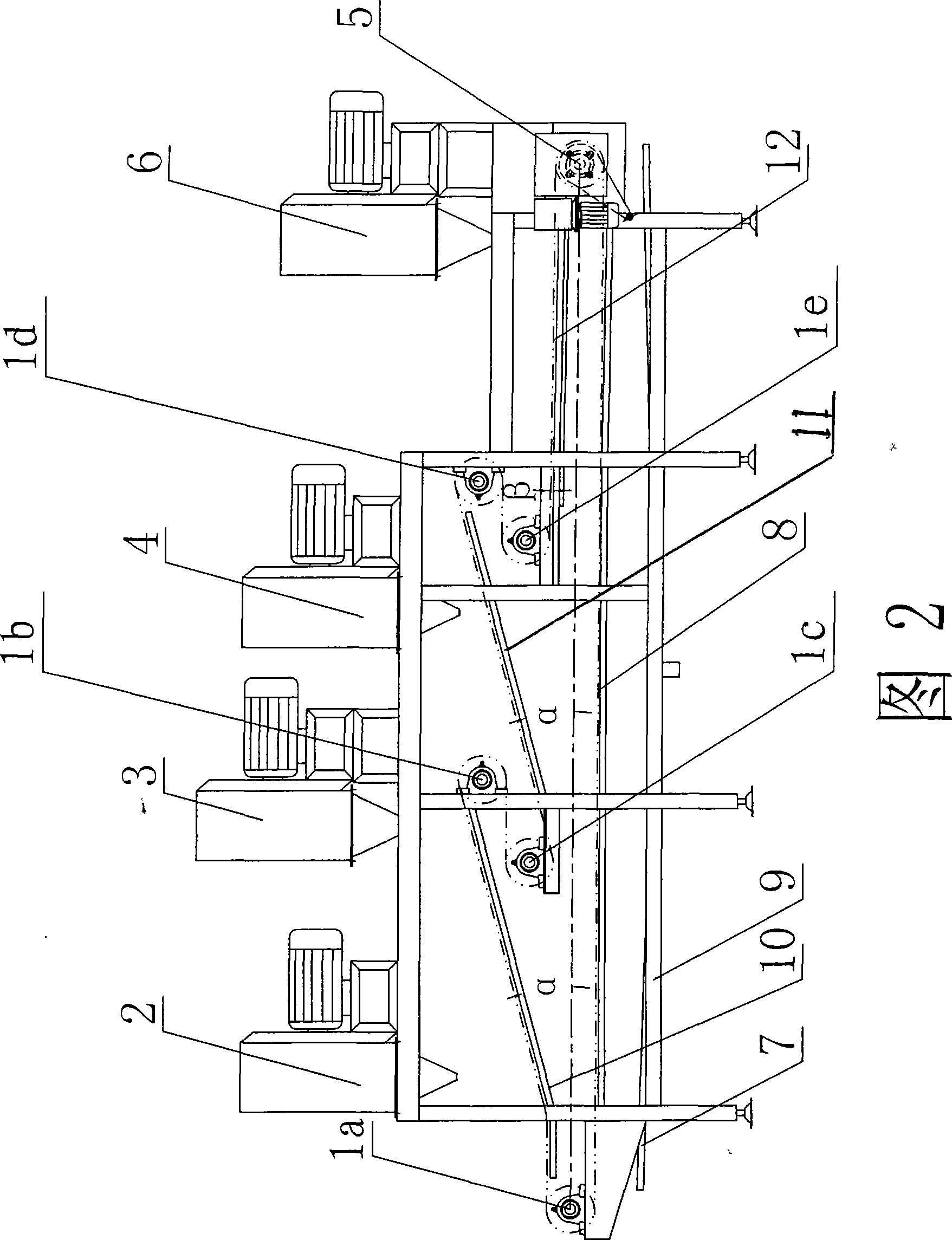

[0012] The present invention consists of the body 9, the driving device 5 and the driven shaft 1a placed at both ends of the body 9, the conveying mesh belt 8 placed between the driving device 5 and the driven shaft 1a, and the 1# spaced distribution on the top of the body 9. Fan 2, 2# fan 3, 3# fan 4, 4# fan 6, and the water receiving tray 7 placed at the bottom of the conveying mesh belt 8 are formed. The conveying mesh belt 8 is arranged in three steps in the body 9. The first The inclination angle α of the first step mesh belt 10 and the second step mesh belt 11 is 12 to 25 degrees respectively, and the inclination angle β of the third step mesh belt 12 is 0 to 10 degrees; the tail of the first step step mesh belt 10 The front part of the second step mesh belt 11 is connected to the transmission through the driven shaft 1b, 1c, and the tail of the second step step mesh belt 11 is connected to the front part of the third step mesh belt 12 through the driven shaft 1d, 1e. ; ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com