Hydraulic low speed power transmission box

A power transmission box and hydraulic technology, which is applied to transmission devices, fluid transmission devices, roads, etc., can solve the problems of occupying the vehicle body space, the power output is not in the best state, and the forward speed of the maintenance vehicle is unstable. Low, reasonable design, high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

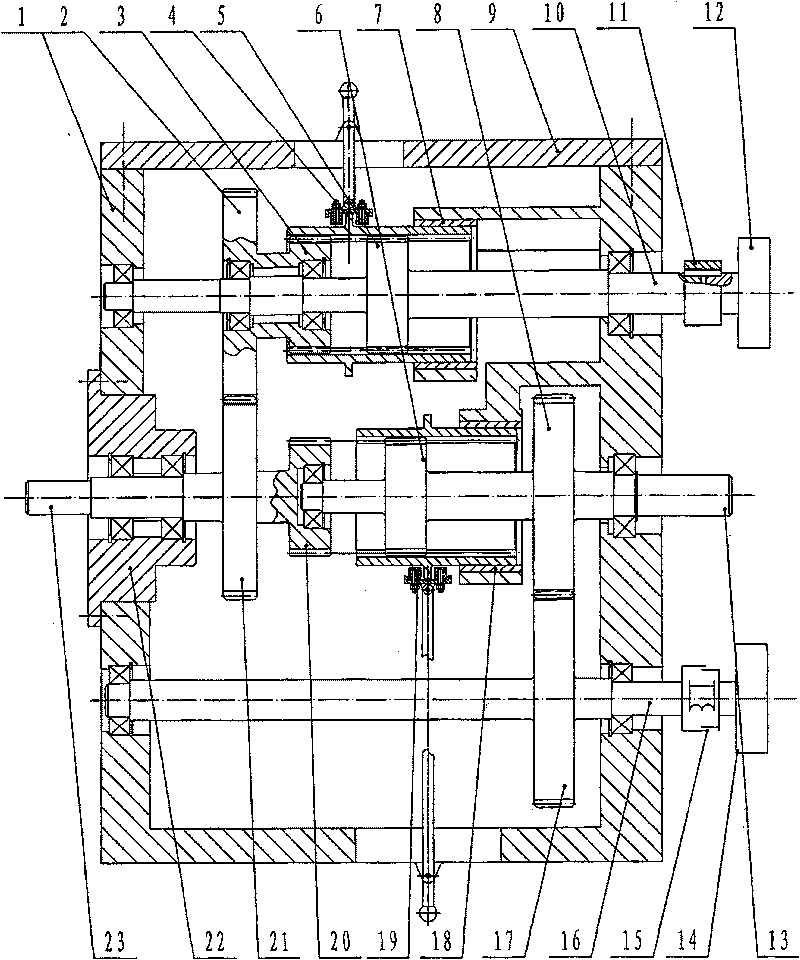

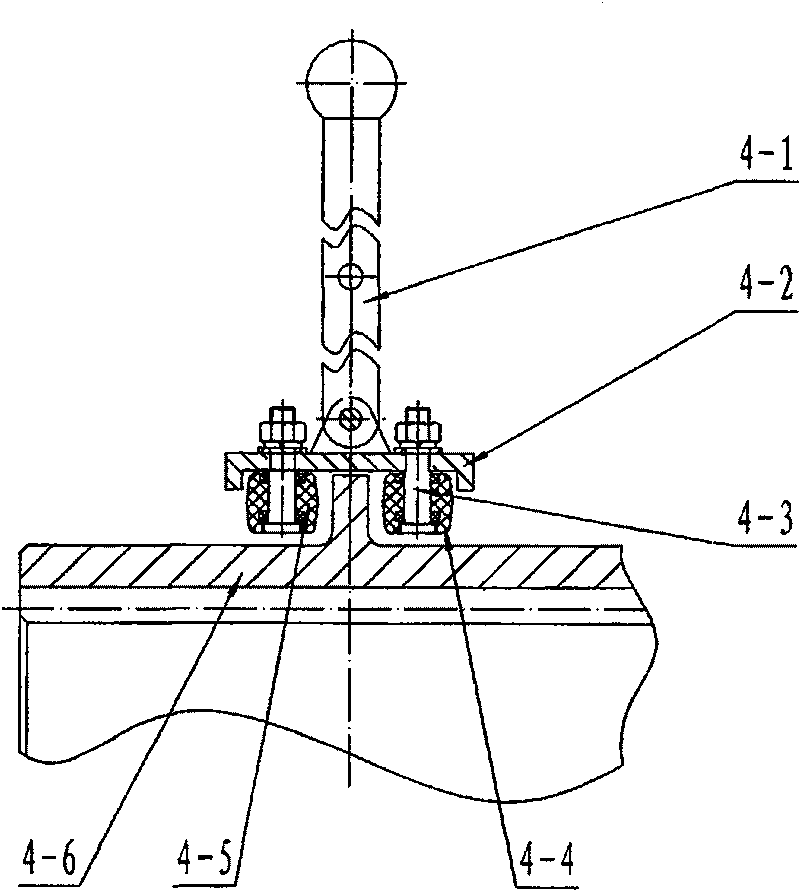

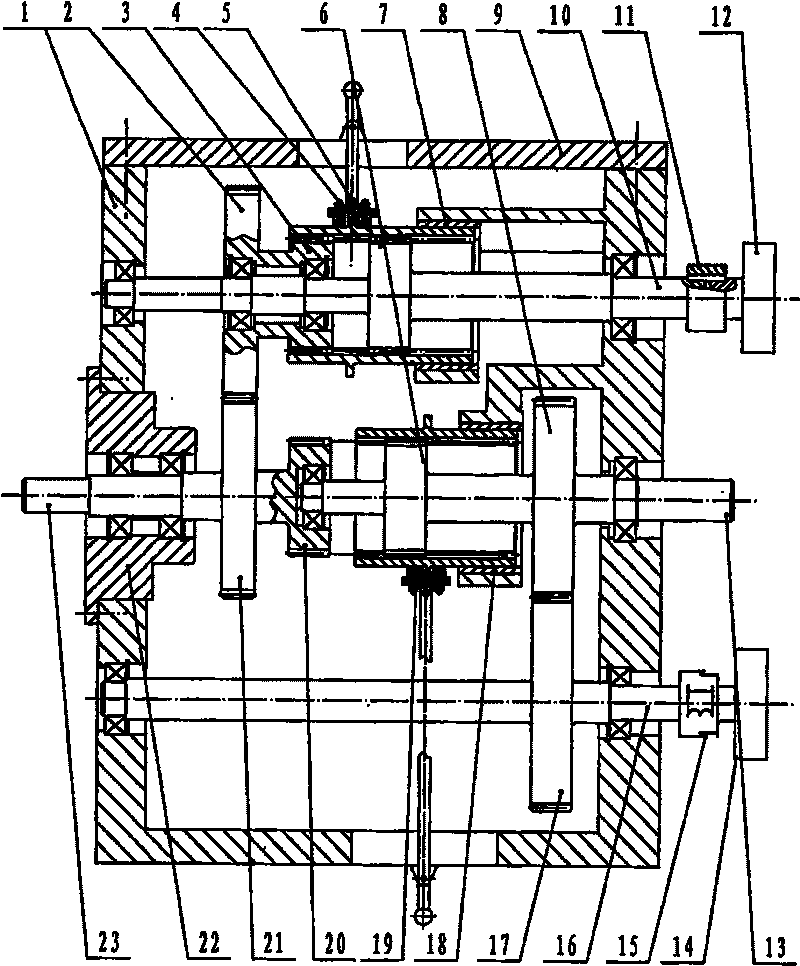

[0013] exist figure 1 Among them, the hydraulic low-speed power transmission box of this embodiment consists of a box body 1, a driven gear 2, a driven fixed gear 3, a hydraulic transmission clutch 4, a hydraulic input fixed gear 5, a hydraulic output fixed gear 6, and a hydraulic output sliding support sleeve 7 , hydraulic driven gear 8, box cover 9, hydraulic output shaft 10, hydraulic pump coupling 11, hydraulic pump 12, power output shaft 13, hydraulic motor 14, clutch 15, hydraulic driving gear shaft 16, hydraulic driving gear 17, The power output sliding support sleeve 18, the power transmission clutch 19, the driving fixed gear 20, the driving gear 21, the bearing seat 22, and the power input shaft 23 are connected to form.

[0014] The upper end of the box body 1 is fixedly connected with a case cover 9 with a threaded fastening joint, and the left middle part of the box body 1 is fixedly connected with a bearing seat 22 with a threaded fastening joint, and a power inp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com