Micro-wave oven

The technology of a microwave oven and a microwave generating device is applied in the field of microwave ovens, which can solve the problems of the complicated hot air convection mechanism of the microwave oven, the inability to increase the temperature in the oven cavity, and the unsatisfactory barbecue effect, and achieves the advantages of ingenious design, simple structure, and accelerated heat distribution. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

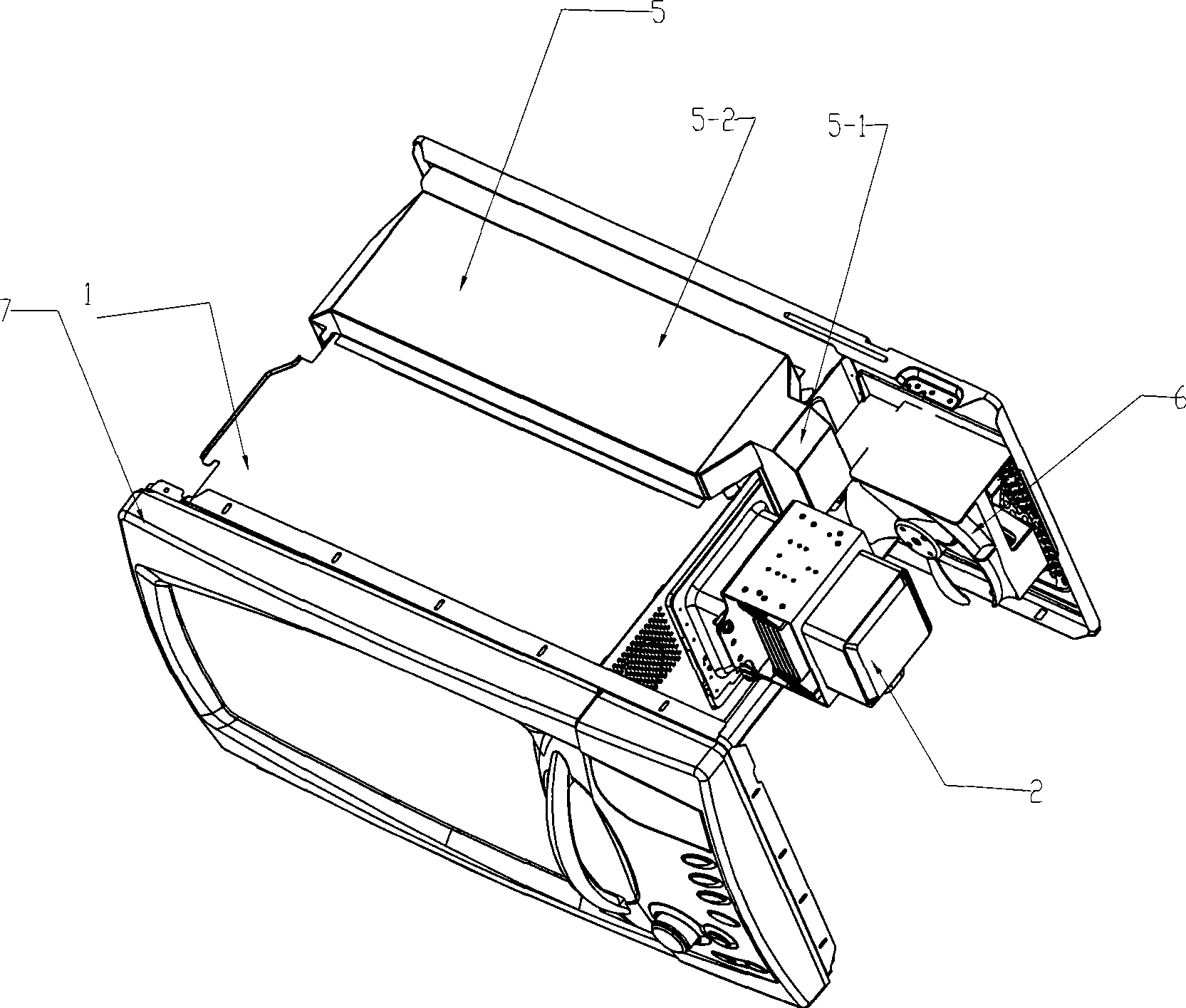

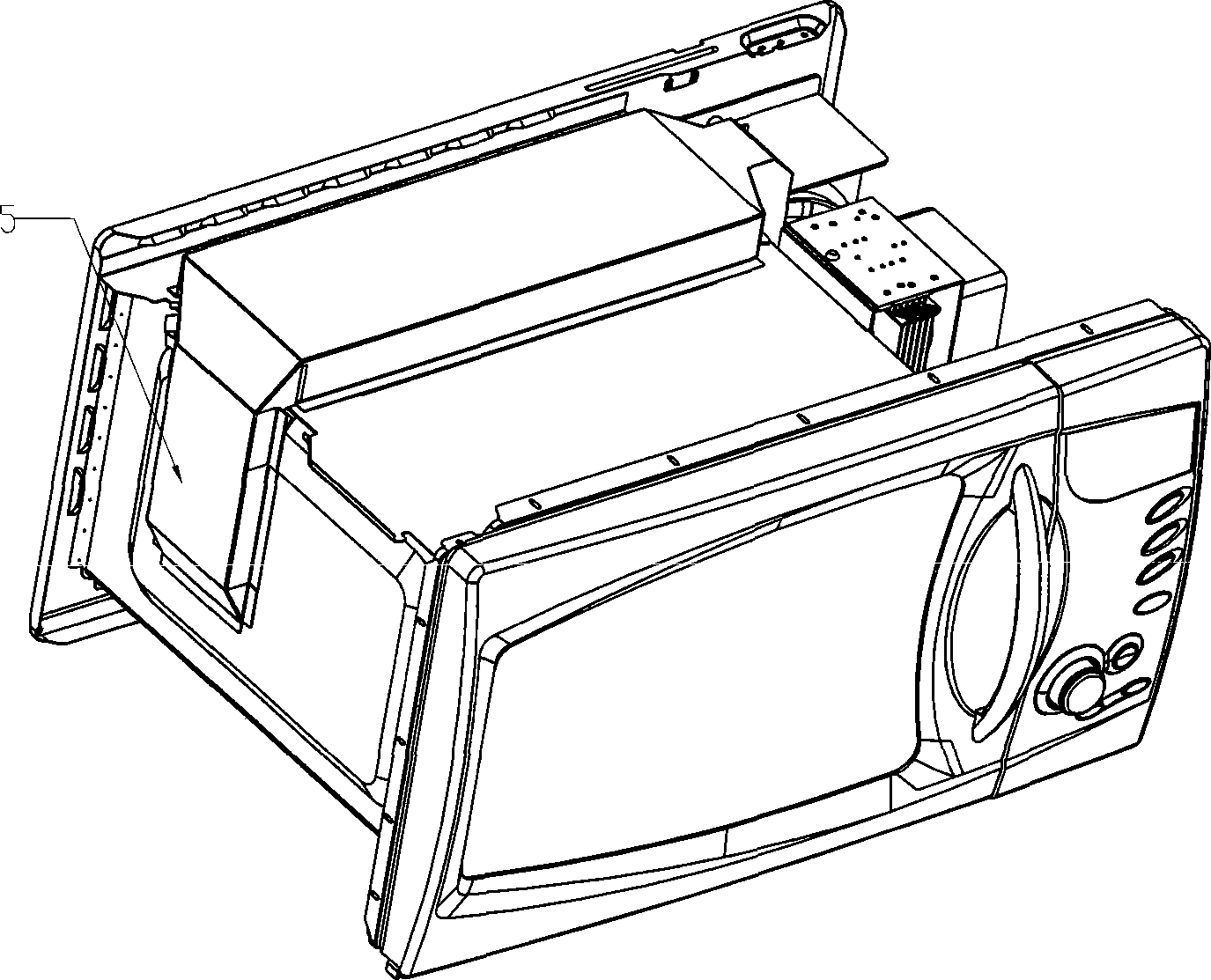

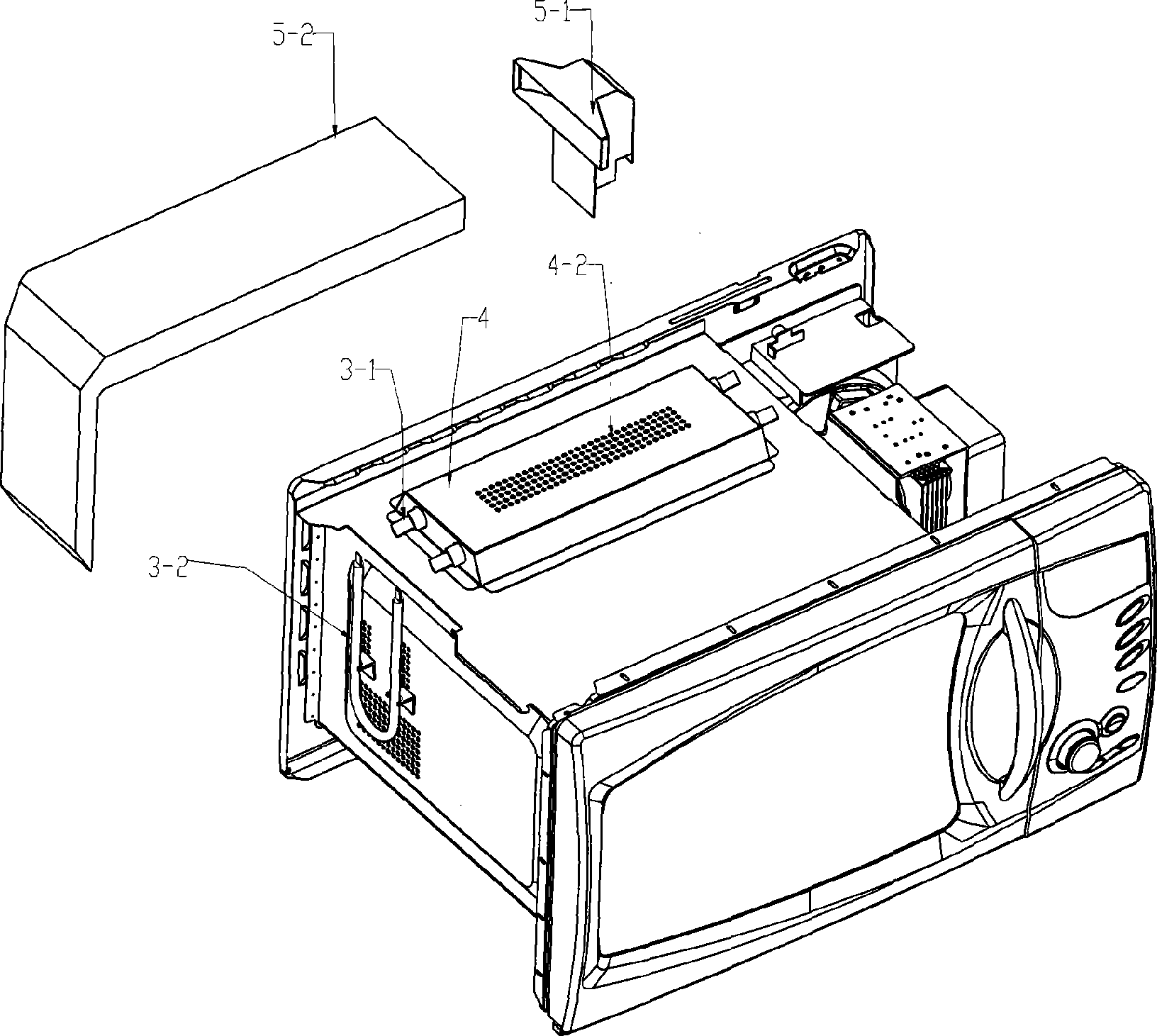

[0018] The structure diagram of the present invention is as figure 1 , 2 , 3, 4, and 5, including a housing 1, a microwave generating device 2, a heating pipe 3, a heating pipe cover 4, an air guide pipe 5, a fan 6, and a door body 7, wherein the heating pipe cover 4 is installed on the shell On the top of the body 1, the heating pipe cover 4 has a hollow cavity, and the heating pipe cover 4 communicates with the cavity surrounded by the housing 1 through the open opening or a number of through holes 4-1 made at the bottom, and the microwave generating device 2 and the fan 6 are installed on one side of the housing 1, wherein the heat pipe 3 includes a heat pipe 3-1 and a heat pipe 3-2, and the heat pipe 3-1 is placed in the hollow cavity of the heat pipe cover 4, through which the The heat pipe cover 4 is supported on the top of the housing 1, the heat pipe 3-2 is placed on the side of the housing 1, the air guide pipe 5 is surrounded by the heat pipe cover 4, the heat pipe ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com