Energy-conserving ventilating method

A ventilation method and an integrated technology, applied in ventilation systems, space heating and ventilation, heating methods, etc., can solve the problems of wasting air, affecting the working environment of the workshop, increasing power consumption, etc., to reduce energy consumption and improve preheating effect Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

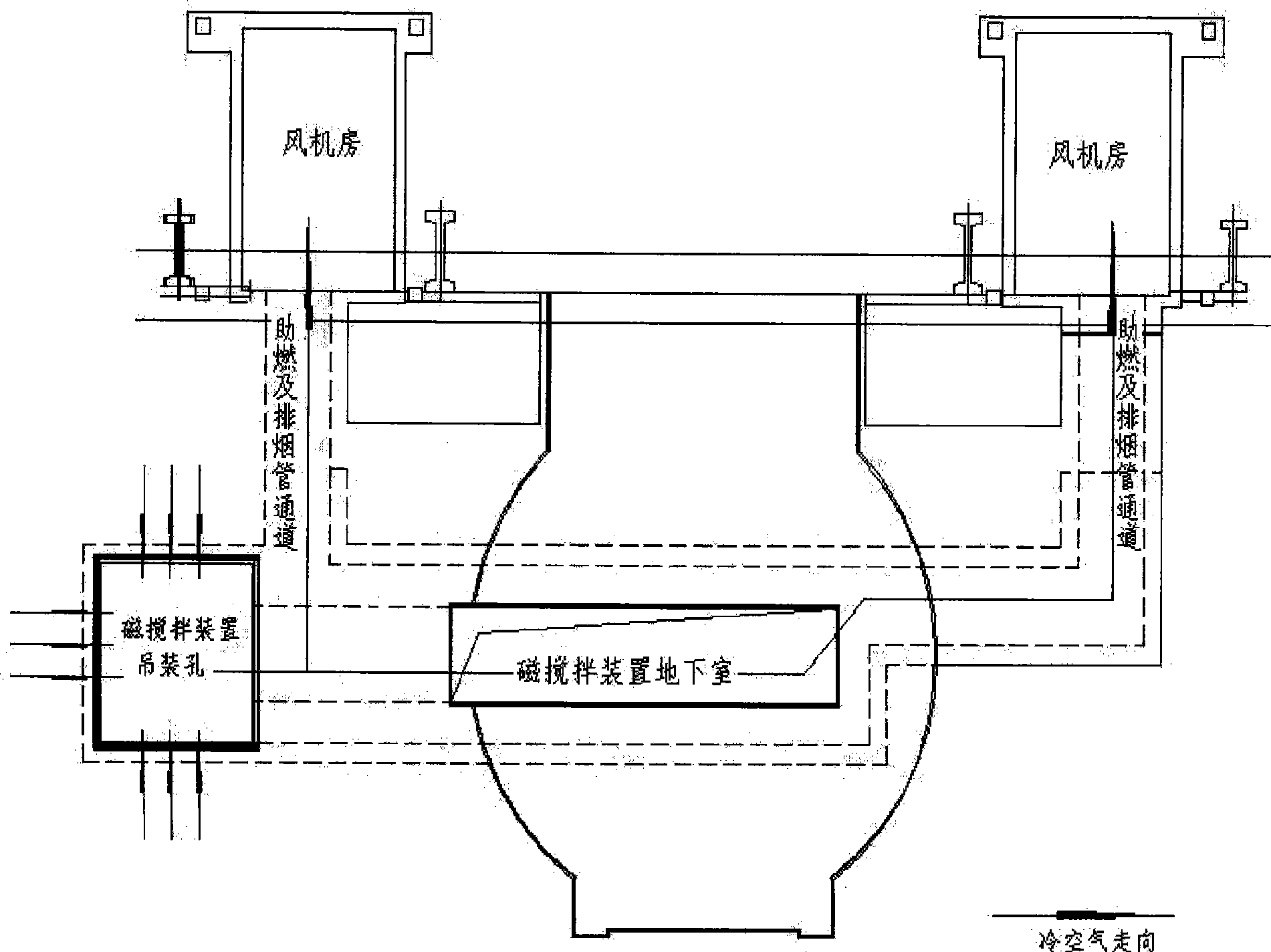

[0012] Make the hoisting hole cover plate of the magnetic stirring device into a mesh cover plate with holes, and the total area of the holes is not less than 2.5m 2 Make the basement of the combustion-supporting air duct of the smelting furnace into a channel to connect the fan room of the smelting furnace and the basement of the magnetic stirring device. After the above two steps are completed, the ventilation channel of the entire basement is formed.

[0013] The combustion-supporting air of the smelting furnace adopts indoor suction, and the combustion-supporting fan is arranged in the fan room of the smelting furnace. The fan room is a noise-reducing airtight room, and only the combustion-supporting air duct channel is connected to the basement of the magnetic stirring device. When the combustion-supporting fan sucks air, it will suck the wind of the entire ventilation channel into the combustion-supporting air duct as combustion-supporting air, forming a negative pressu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com