Low-cycle fatigue damage quantitatively characterizing method based on metal magnetic memory detection technology

A metal magnetic memory and low-cycle fatigue technology, applied in the direction of material magnetic variables, can solve the problem of inability to quantitatively characterize fatigue damage, and achieve the effect of a reliable quantitative mechanical characterization method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

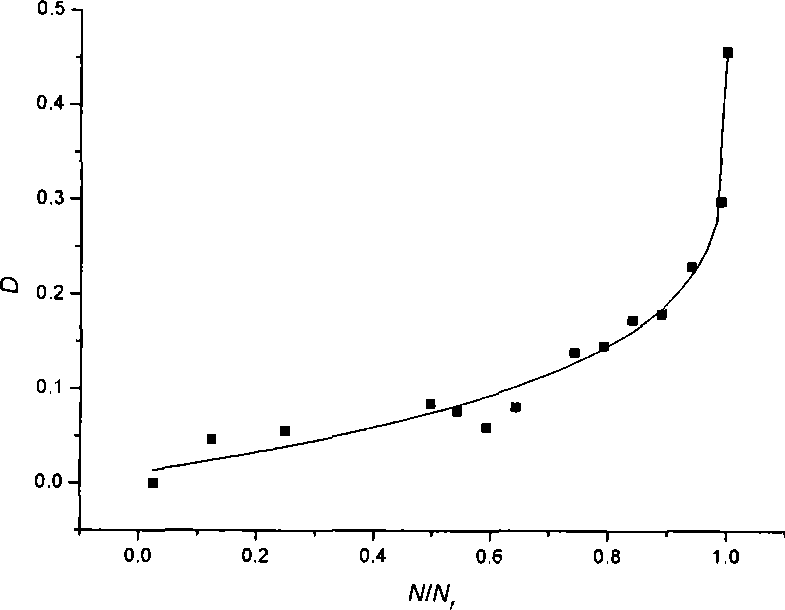

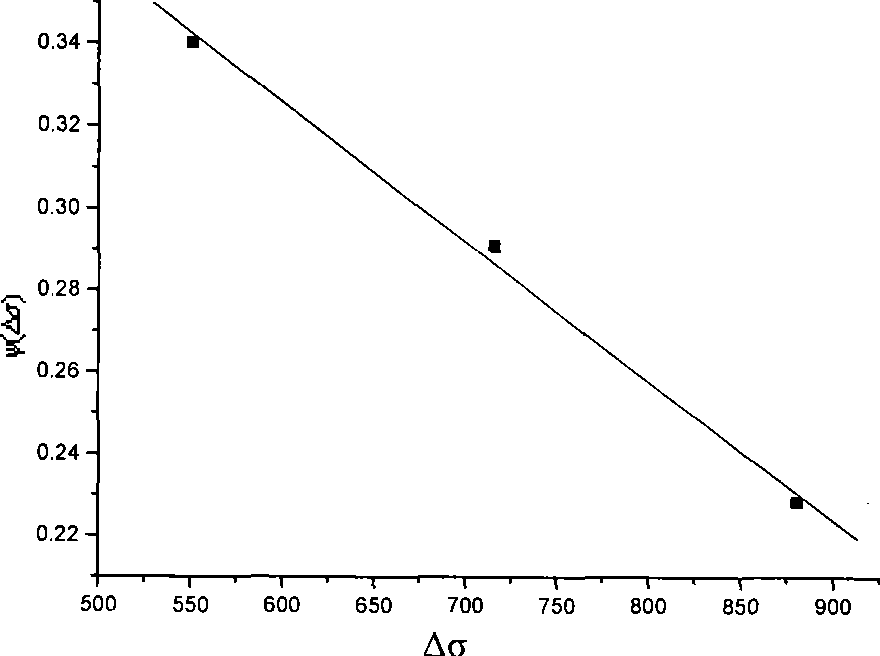

[0041] Corresponding stress concentration factor K t = 3 notched pieces were subjected to fatigue tests at three different low-cycle fatigue stress levels (the fatigue stresses were 0.93σ 0.2 , 0.76σ 0.2 and 0.58σ 0.2 ), using the Xiamen Edson EMS2003 intelligent magnetic memory / eddy current detector to detect the metal magnetic memory signal of the notched parts under different fatigue cycles. According to steps 1 to 5 of the technical solution, the magnetic memory signal characteristic parameters and related data are processed, and a continuous damage mechanics low cycle fatigue damage model based on the magnetic memory signal characteristic parameters is established. They are as follows:

[0042] Based on the magnetic memory signal characteristic parameter H p (y) sub The low cycle fatigue damage model:

[0043] 0.93σ 0.2 :D=0.45-0.43868(1-N / N f ) 0.22836 (7)

[0044] 0.76σ 0.2 :D=0.45-0.27767(1-N / N f ) 0.29091 (8)

[0045] 0....

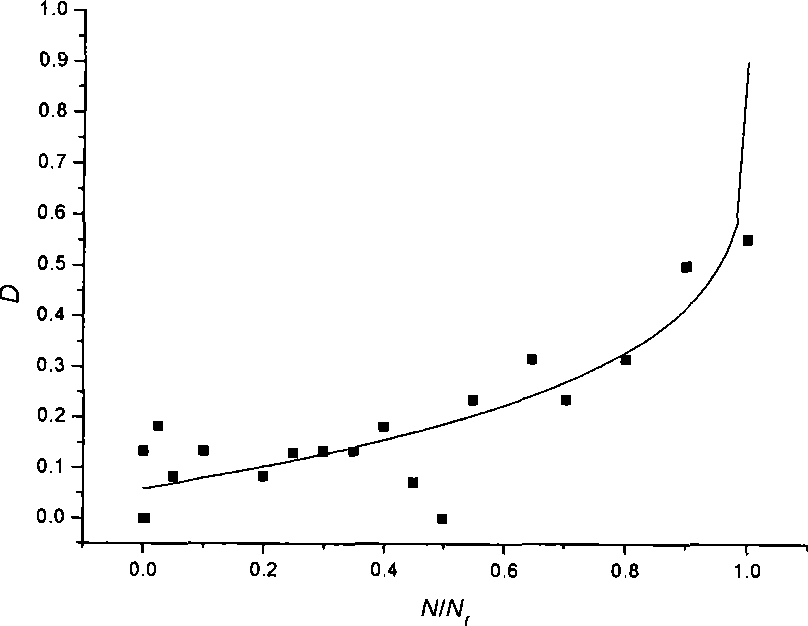

Embodiment

[0060] Example: Stress Concentration Factor K t The notch of =5 is based on the characteristic parameter H of the magnetic memory signal p (y) sub Characterization of low cycle fatigue damage

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com