Method for manufacturing timber key

A key and wood technology, which is applied in the field of making keys with wood, can solve problems such as pocket sagging, battery discharge, and inability to use mobile phones, etc., and achieve weight reduction, soft touch, and high-quality effects

Inactive Publication Date: 2010-12-01

李英儿

View PDF0 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Thereby, the problem that the key body 6 that uses above-mentioned metal material to make exists is, the first: for the user who needs to wear a plurality of keys, the weight of the key that will carry every day is quite heavy, if key chain is contained in the pocket , then, the pocket will sag, affecting the shape of the clothes; second: if the key body 6 of metal material is placed in the pocket together with the mobile phone, the key body 6 of metal material may be in contact with the charging end of the battery of the mobile phone and cause the battery to discharge, Therefore, it will be impossible to use the mobile phone; third: some users will be allergic to some metal materials according to their physique, but this problem cannot be solved

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

A method for manufacturing timber key comprises a timber-pressing step to press timbers; a unit-timber forming step to form unit timbers from the pressed timbers through said timber-pressing step; a unit-timber forming step to form unit timbers, each of the unit timbers being obtained by cutting a timber pressed through said timber-pressing step into a plurality of pieces; a key-outline forming step where a unit timer formed through said unit-timber forming step is cut at edge thereof so that the cut unit timber might have a key outline consisting of a key body in distinction from a grip partas attached at one end of the key body; a unit-key cutting step to form a plurality of unit keys by cutting a unit timber having a key outline formed through said key- outline forming step; a unit-key processing step to process the key body part and grip part of a unit key prepared through said unit-key cutting step; and further a step of forming ornaments on grip part and unevenness on key body of a unit key prepared through said unit-key processing step, thereby a key manufactured according to these steps is light in weight, soft to the touch so as to make a high-grade product, and capable of replacing a key body made of metallic material of traditional art.

Description

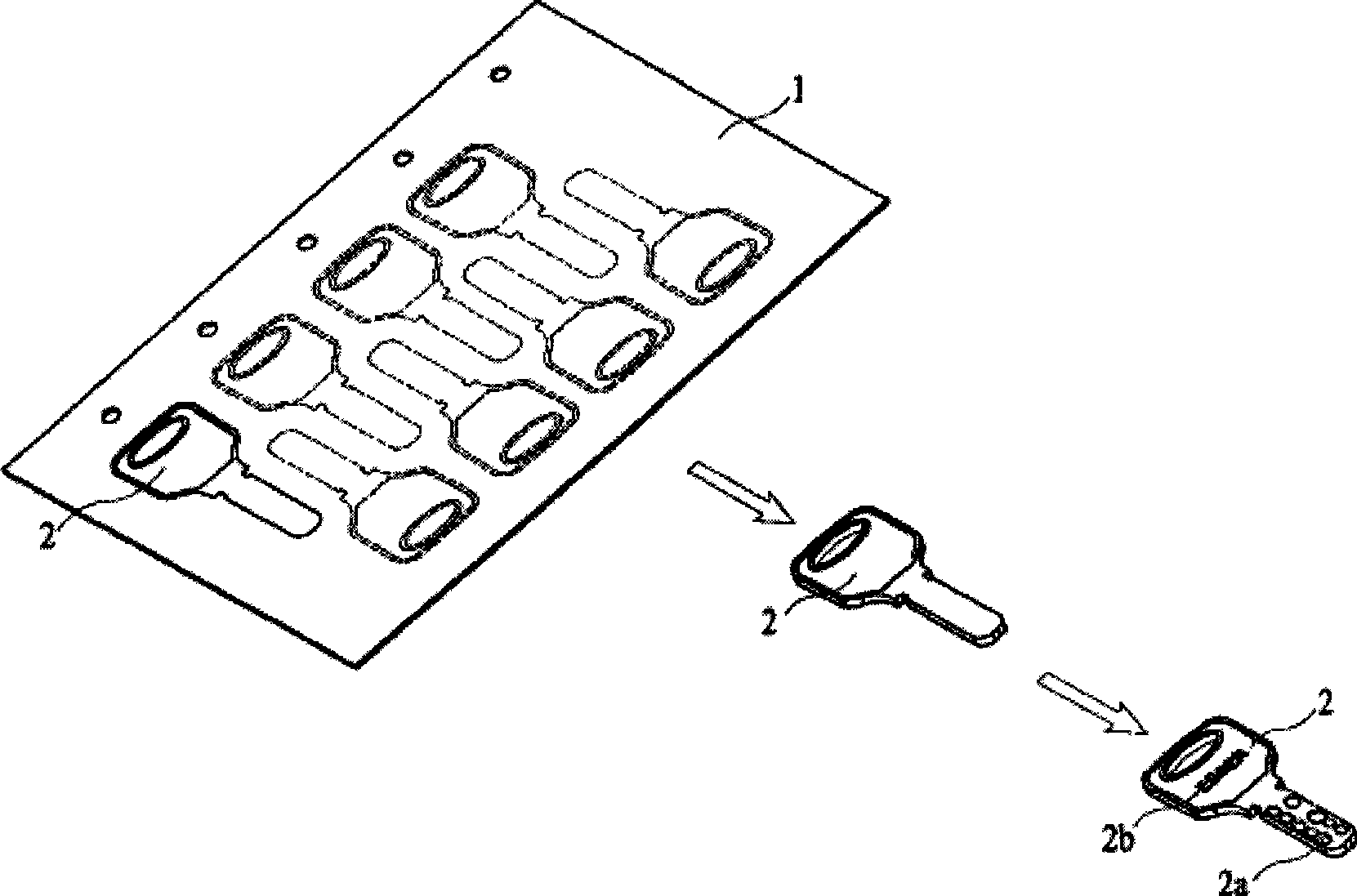

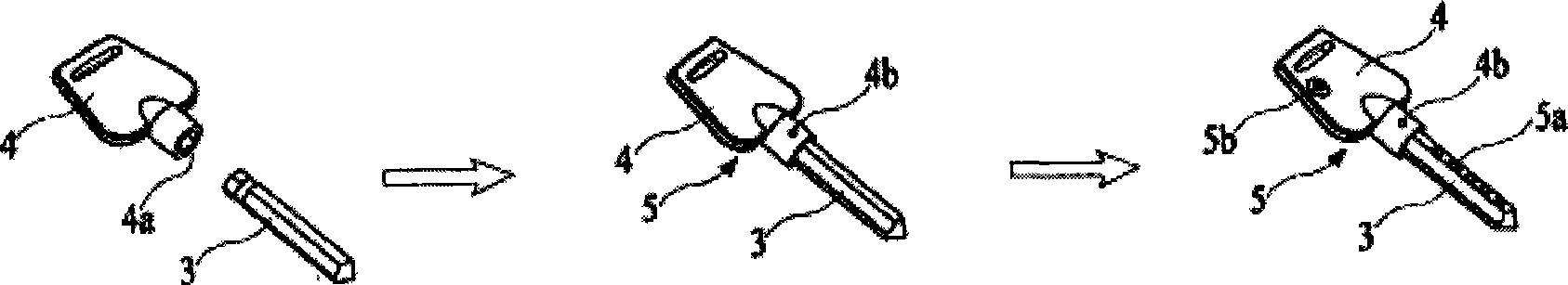

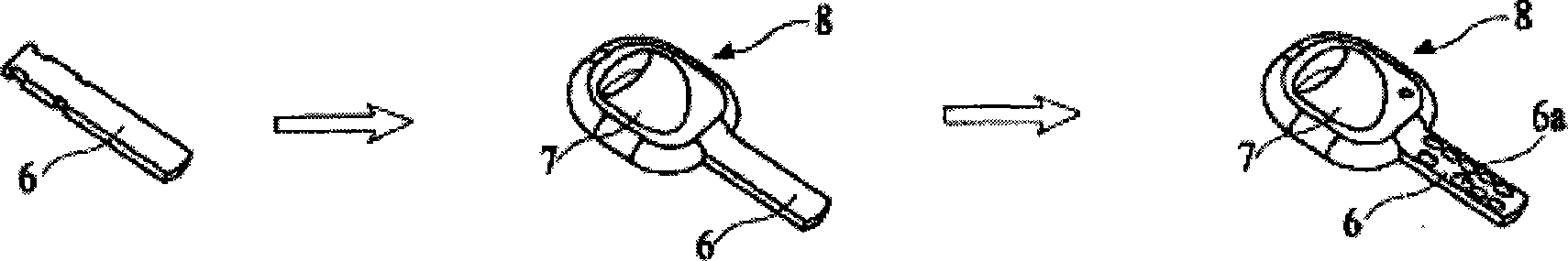

How to make keys from wood technical field The present invention relates to a method for making a key by using wood, in particular to a method for making a key by using wood to make a key with light weight, soft touch and high-quality appearance, which can replace the conventional metal material key body. Background technique Usually, the key used for opening and closing the lock head is divided into a handle and a key body, and its material is generally metal or metal and synthetic resin. As the above-mentioned method of manufacturing a key, the most common method is as shown in FIG. 1. While moving the metal plate 1, a key base material 2 in the shape of a key is punched out on the metal plate 1 by using a press die. Desired key grooves 2a and patterns 2b are formed on the key substrate 2, thereby obtaining a final product. Or as shown in Figure 2, after the key body 3 and the handle 4 are formed respectively, the key body 3 is inserted into the hole 4a formed on the h...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): B27M1/08

CPCB27M1/02B27M3/00

Inventor 李英儿

Owner 李英儿

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com