Fuel injection valve for internal combustion engines

A technology for fuel injection valves and internal combustion engines, which is applied in the direction of fuel injection pumps, fuel injection valves driven by fluid pressure, fuel injection devices, etc., and can solve disadvantages and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

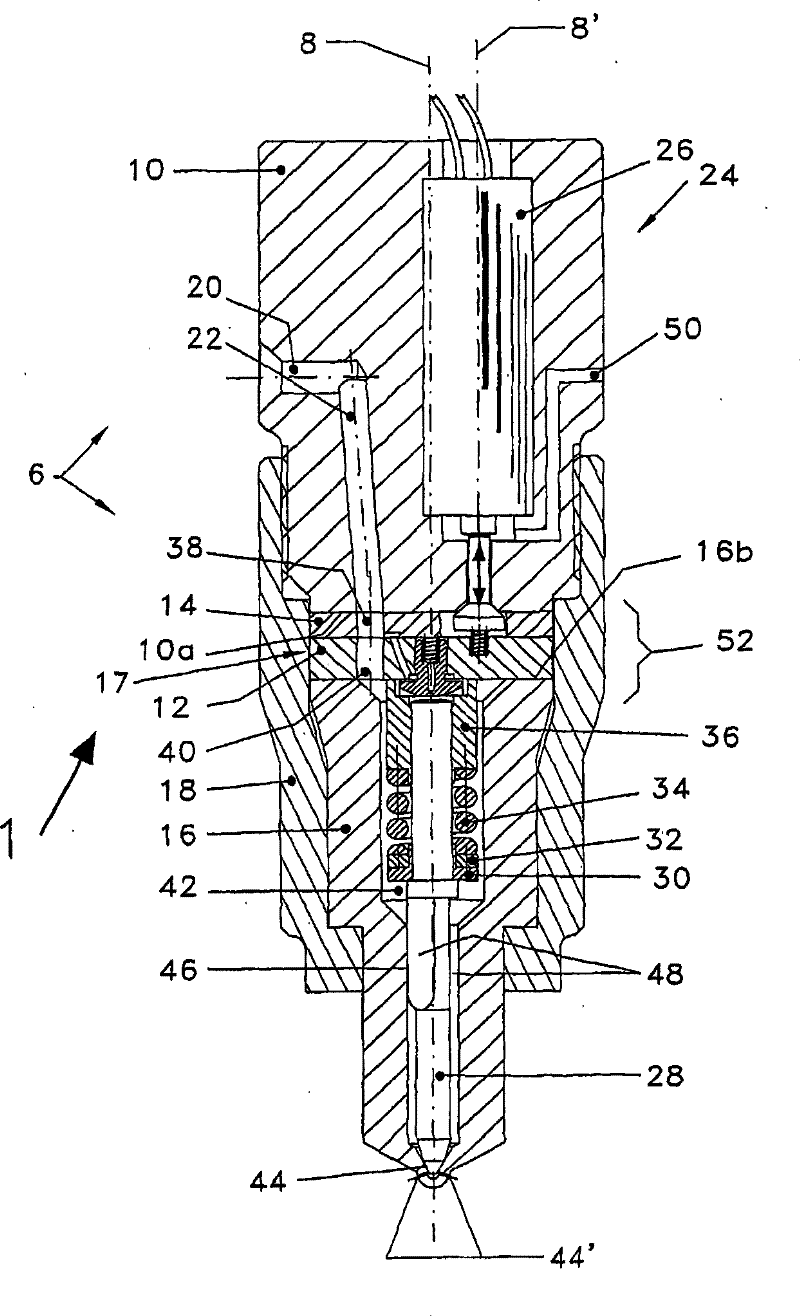

[0028] figure 1 A fuel injector 1 is shown for intermittently injecting fuel into a combustion chamber of an internal combustion engine. The fuel injection valve has an elongated cylindrical and stepped housing 6 , the housing axis of which is indicated by 8 . The housing 6 is composed of a housing body 10 , a first intermediate plate 12 , a second intermediate plate 14 and a nozzle body 16 . The first intermediate plate 12 and the second intermediate plate 14 form an intermediate part 17 . The first intermediate plate 12 and the second intermediate plate 14 and the nozzle body 16 are clamped in a sealing manner against each other and against a bottom surface 10 a of the outer housing 10 by means of a union nut 18 designed as a cap nut. The first intermediate plate 12 rests here against the nozzle body 16 , and the second intermediate plate 14 rests here against the outer housing 10 .

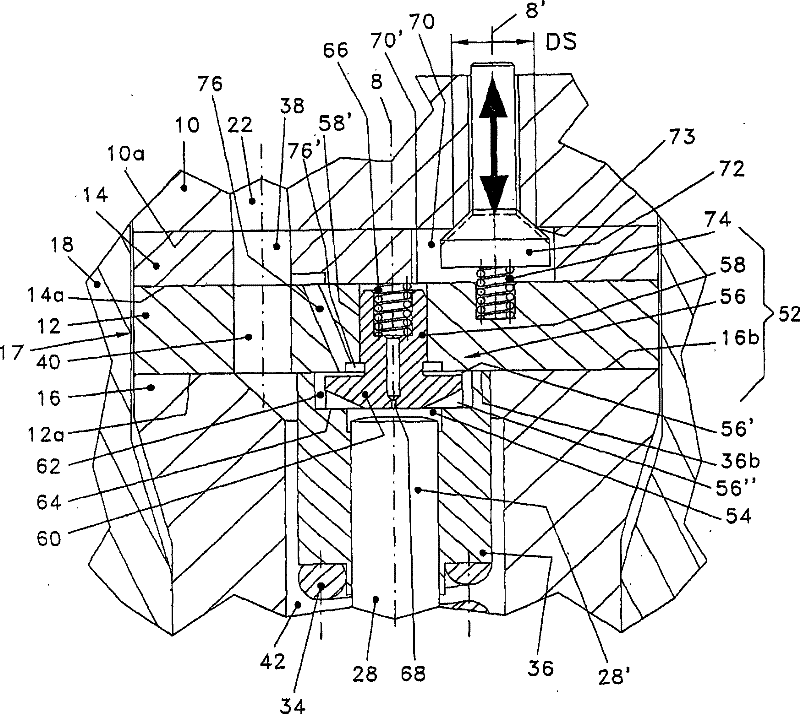

[0029] A high-pressure fuel inlet 20 designed as a high-pressure delivery hole of the f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com