Power units for all-round forklifts

A power unit, all-round technology, applied in the direction of lifting devices, etc., can solve the problems of power waste, wasted pump power, damaged work efficiency, etc., and achieve the effect of reducing installation steps, rapid output flow, and fast response speed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

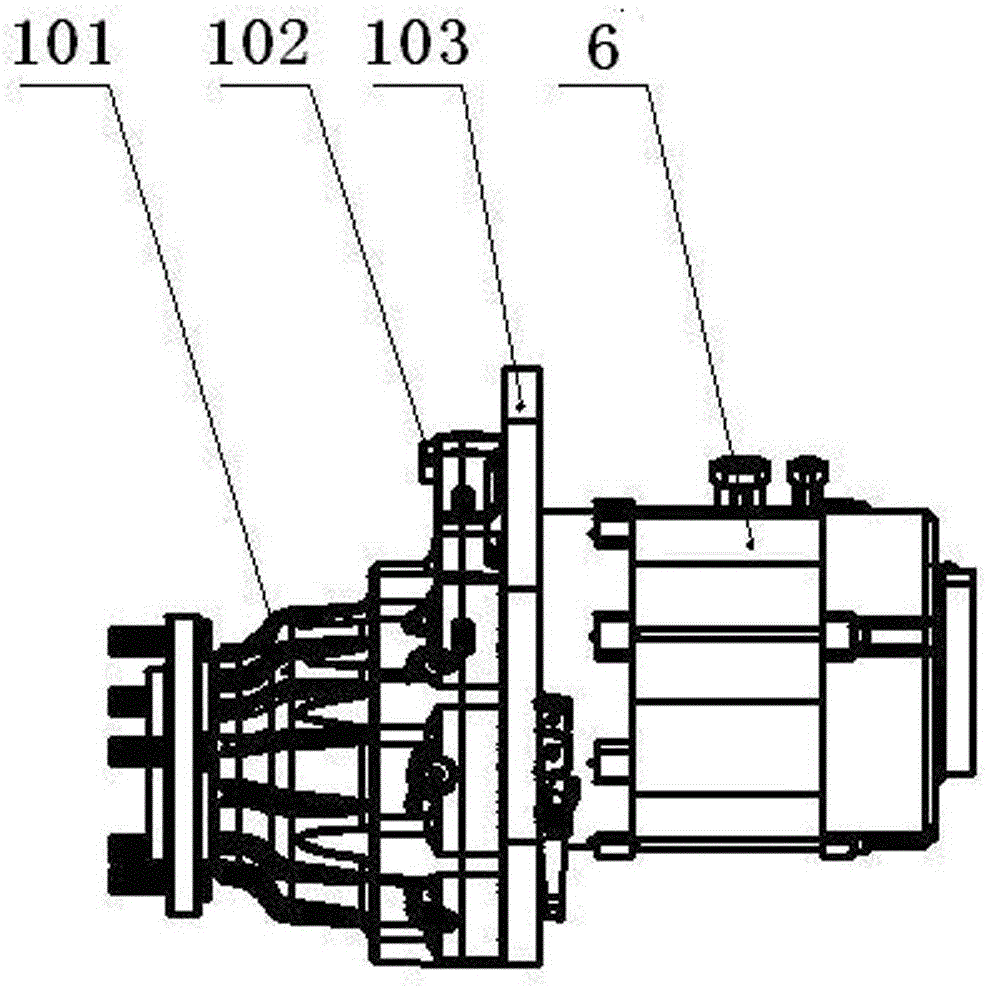

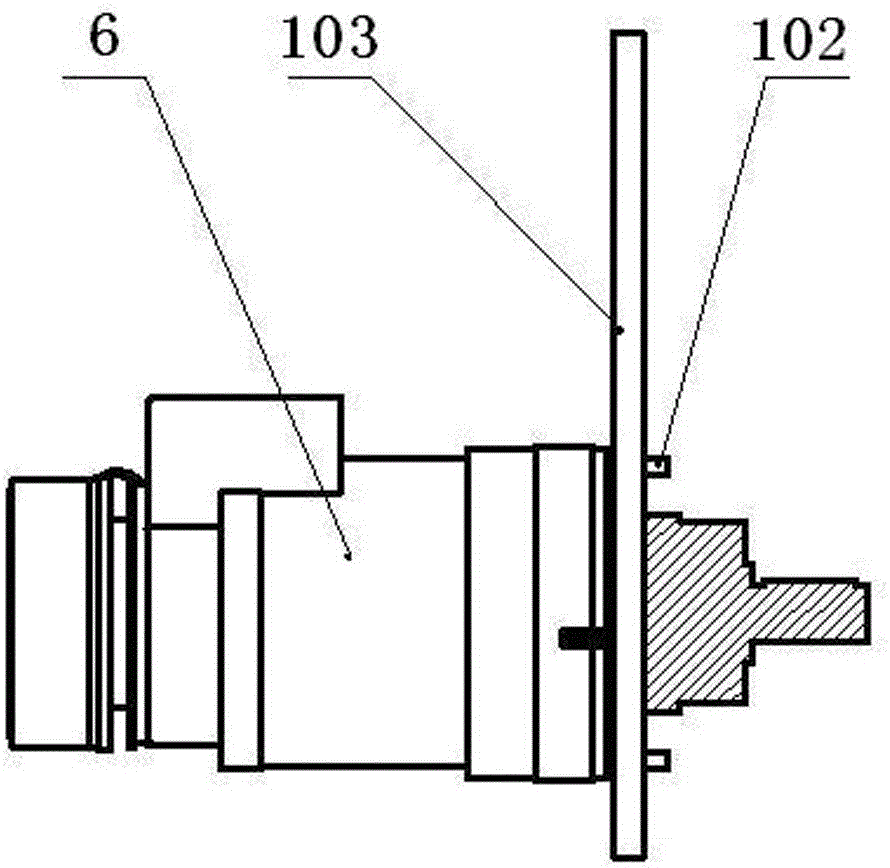

[0081] refer to image 3 , which shows a schematic diagram of a power unit for an all-round forklift according to the present invention, wherein the drive motor 6 is fixed on the frame 103 through fasteners 102, which makes the drive motor 6 directly provide power to the tires.

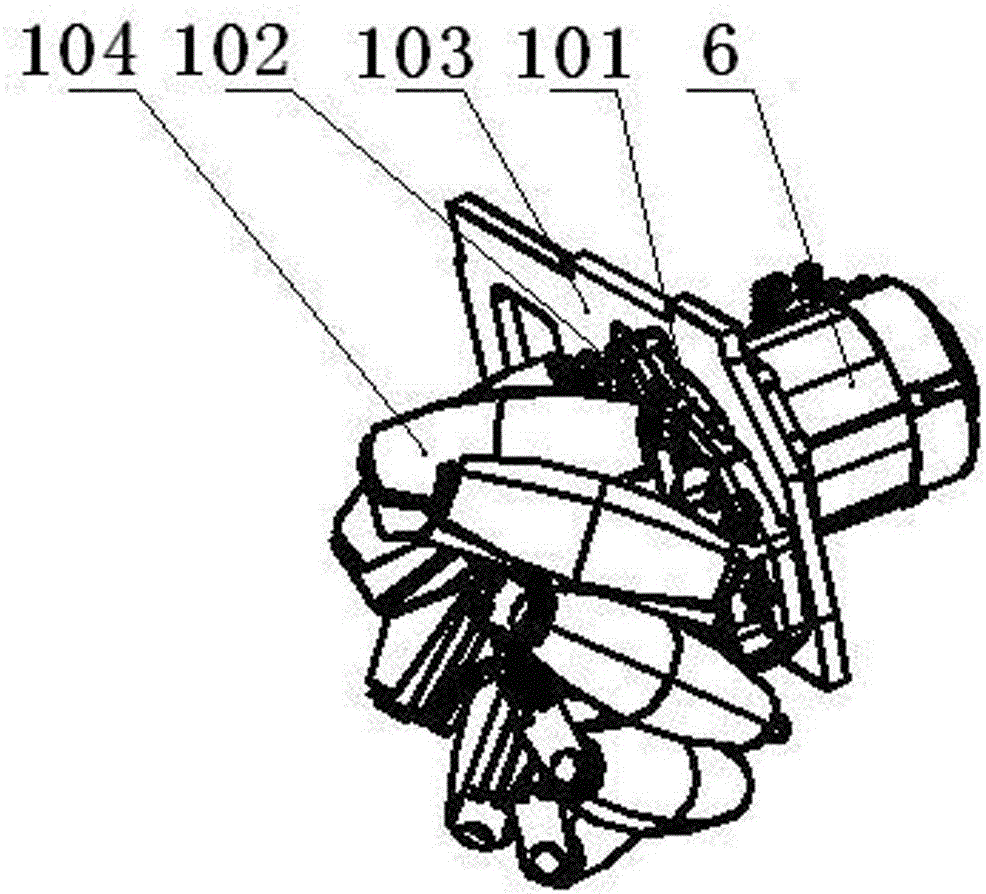

[0082] Refer again Figure 4 , which shows a schematic diagram of a power unit driving an omnidirectional wheel for an omnidirectional forklift according to the present invention, wherein the driving motor 6 is fixed on the vehicle frame 103 through fasteners 102, a wheel rim 105 is installed on the vehicle frame 103, and the driving motor 6 passes through Bearing 106 and fastener 102 are connected on the omnidirectional wheel 104, and omnidirectional wheel 104 and rim 105 are fixed by fastener, and during work, drive motor 6 drives bearing 106 to rotate, and bearing 6 supports the operation of omnidirectional wheel 104.

[0083] By adopting the power unit for the all-round forklift of the present in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com