Shift device

A shifting device and shifting fork technology, which is applied in the direction of mechanical control devices, transmission device control, and components with teeth, etc., can solve problems such as longitudinal bending and shifting fork shaft distortion, and achieve simplicity, cost, and space saving , the effect of less structural space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

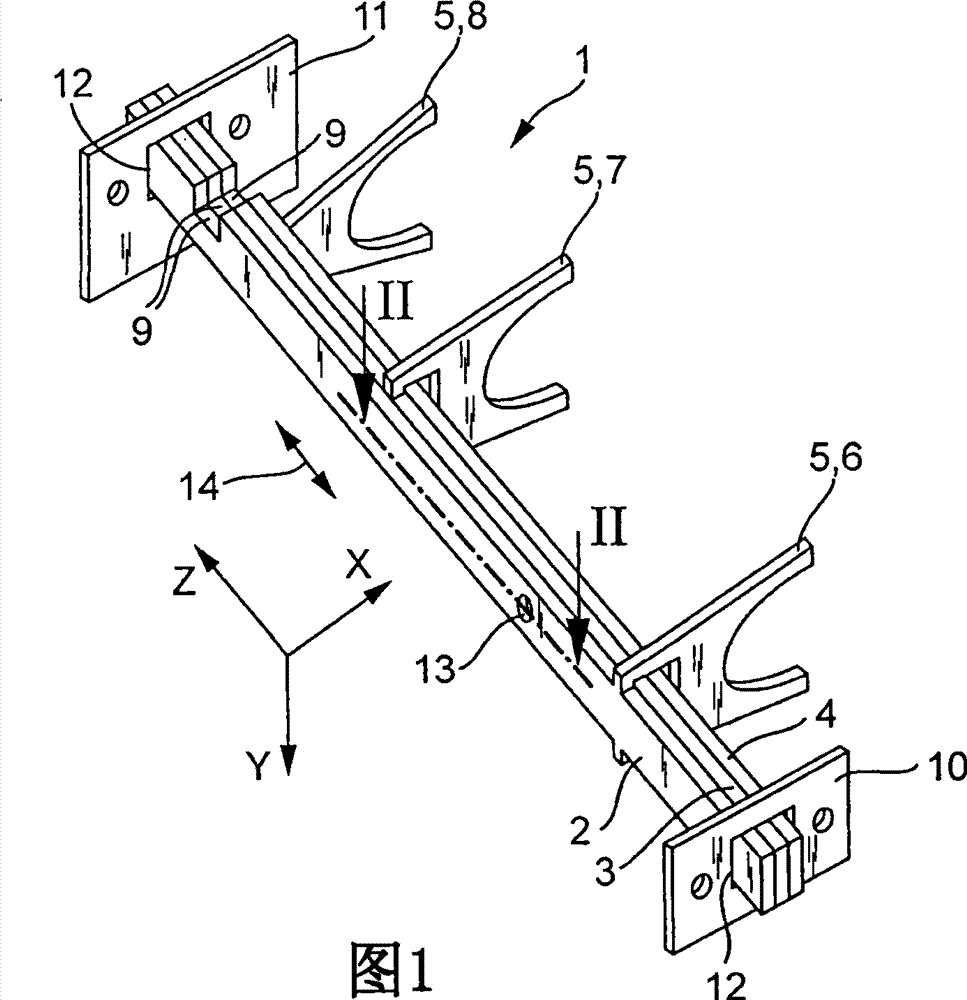

[0021] FIG. 1 illustrates a shift device 1 with a bundle of shift fork shafts 2, 3 and 4. Each shift fork shaft 2, 3, 4 has one of shift forks 6, 7 or 8 and a shift opening 9 as an operating member 5. The shift fork shafts 2, 3, 4 are slid or rolled longitudinally movably in the bearing end caps 10 and 11 along the parallel Z longitudinal direction indicated by the double arrow 14 by means of the support 12 not described in detail.

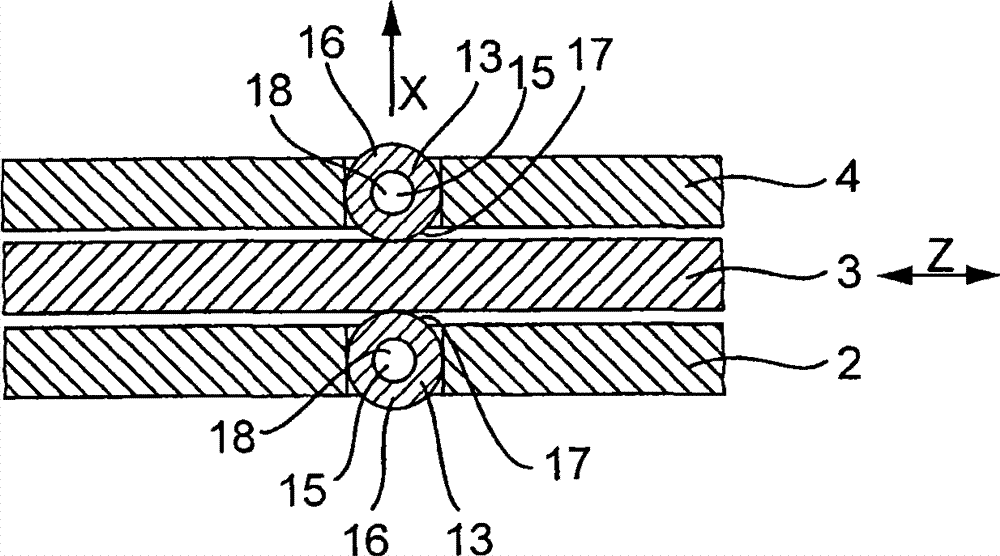

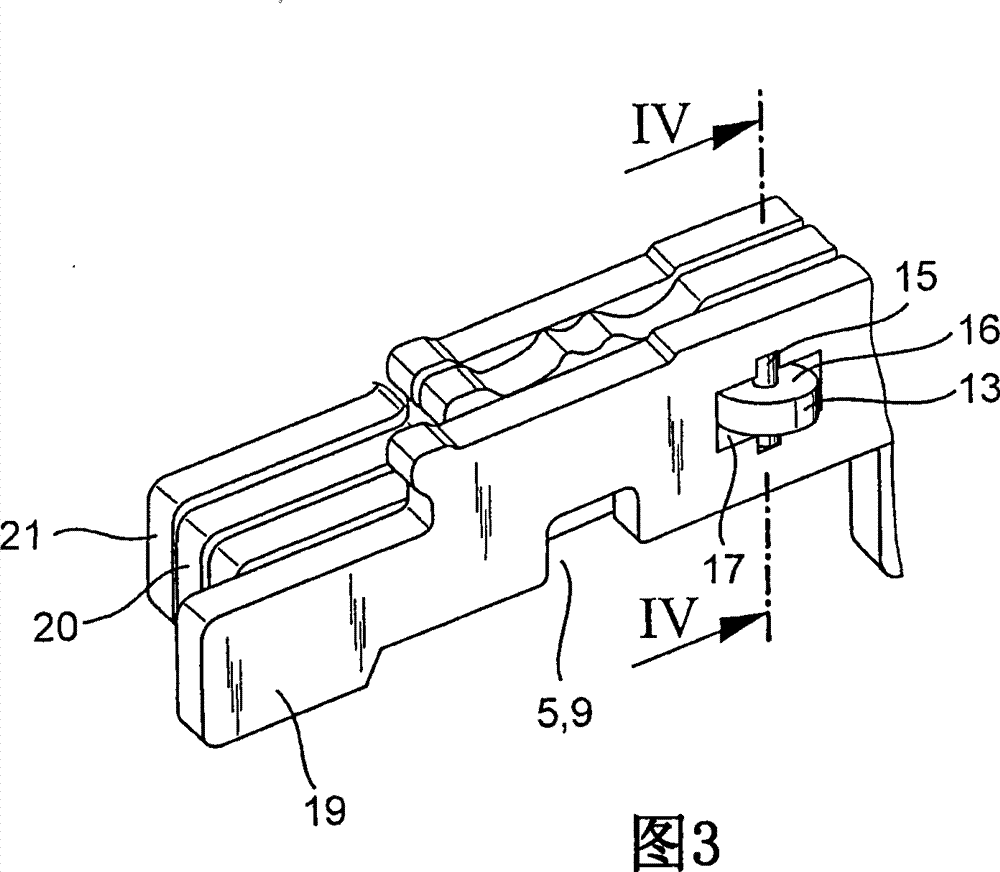

[0022] The shift fork shafts 2 and 4 also each have at least one roller bearing 13. Roller bearing 13 in figure 2 The center is shown in cross-section and each consists of a pin 15 and a roller 16. The pin 15 is fixedly held in the receiving place 17 of the respective shift fork shaft 2 or 4 and the shaft is used for a roller 16 rotatably supported on the pin 15. The roller 16 can be rotatably slid or rolled on the pin 15 around the longitudinal center axis 18. It is also conceivable that instead of one roller, a plurality of rollers are supported...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com