Semiconductor device

A technology of semiconductors and internal wires, applied in semiconductor devices, semiconductor/solid-state device components, electric solid-state devices, etc., can solve problems such as difficult injection of resin and obstruction of resin flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

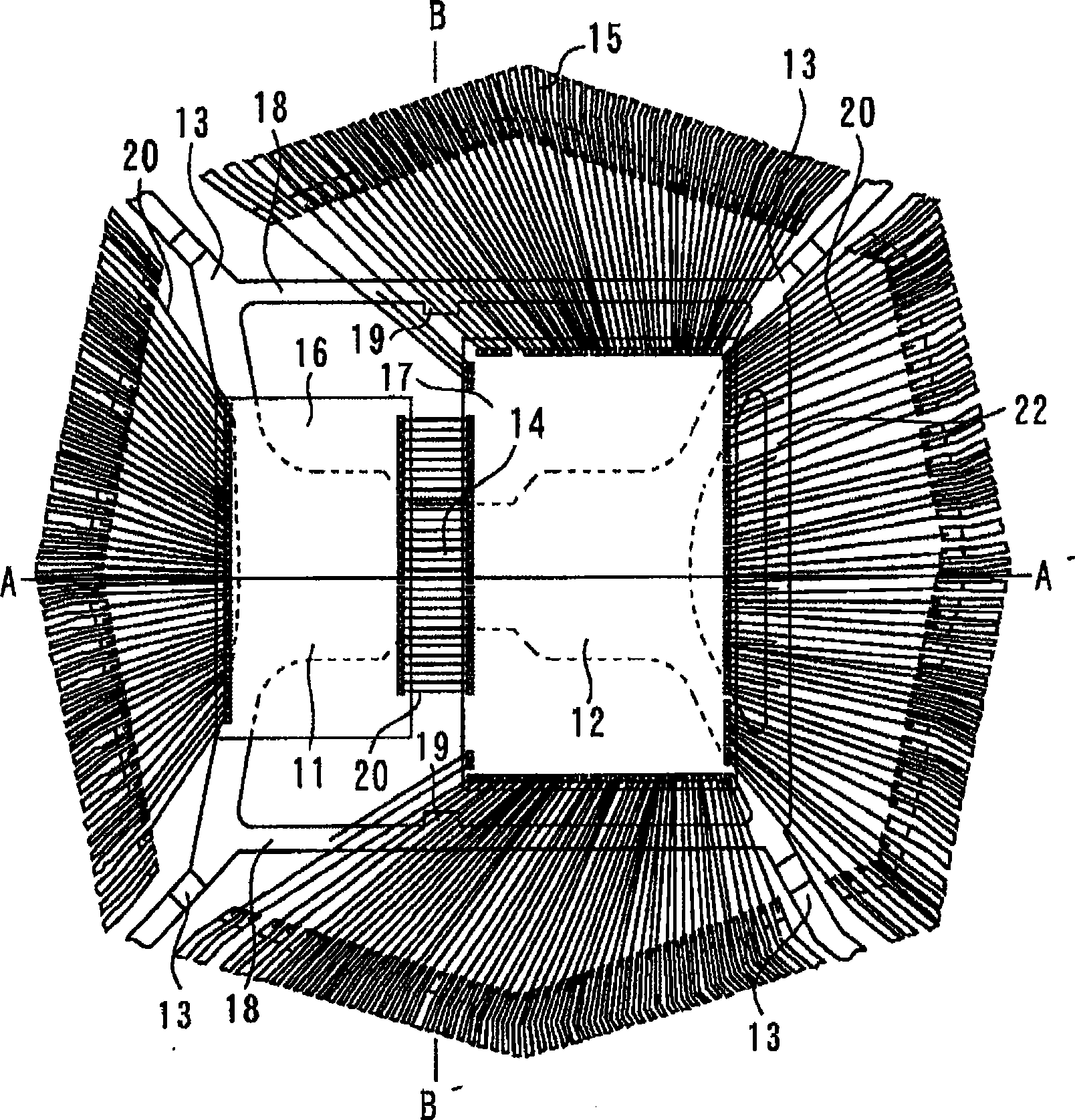

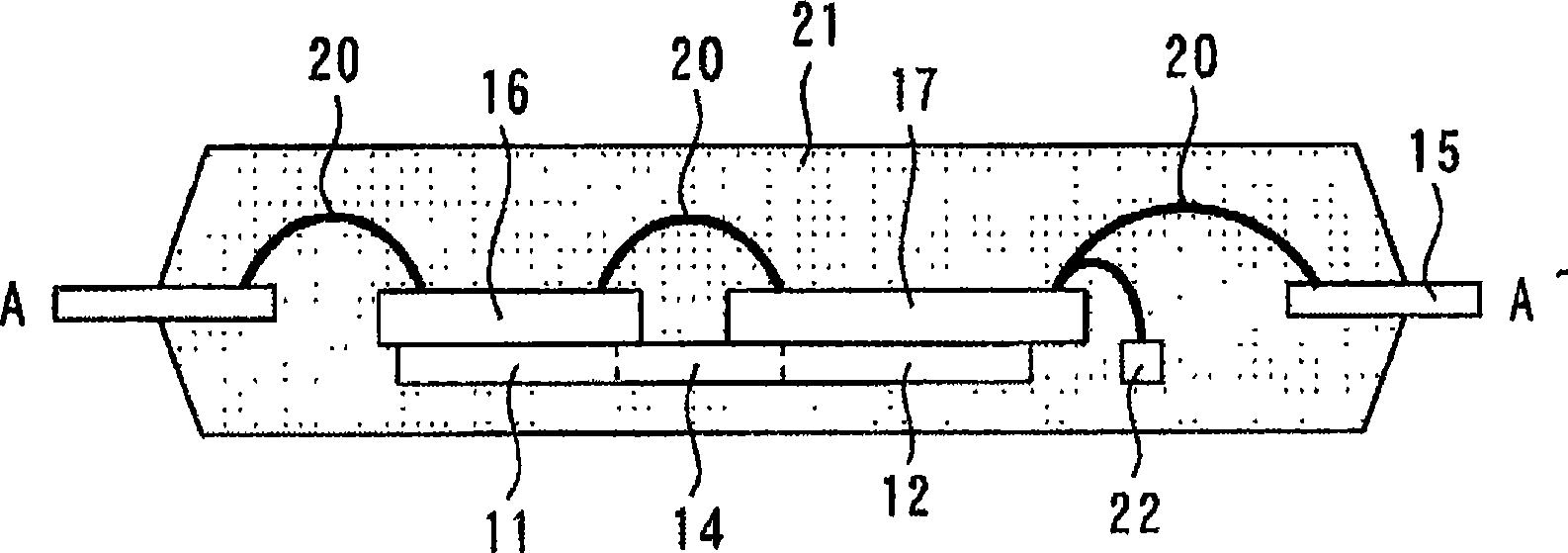

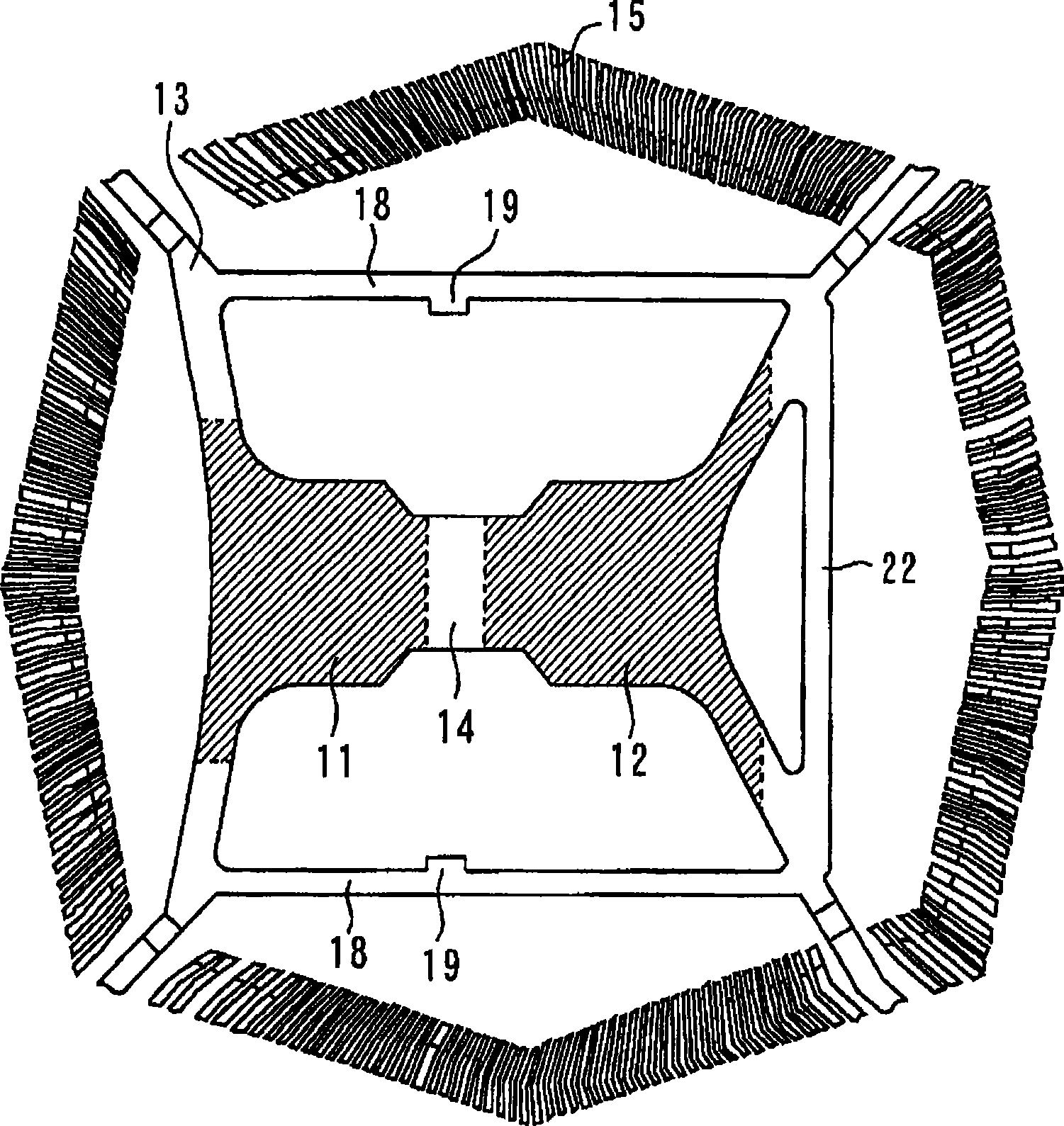

[0027] figure 1 is a plan view showing the inside of a semiconductor device according to an embodiment of the present invention, figure 2 yes figure 1 Cross-sectional view of A-A′. Figure 10 yes figure 1 Cross-sectional view of B-B′. The first lower backing plate 11 (first portion) and the second lower backing plate 12 (second portion) are arranged side by side. The first and second lower backing plates 11 , 12 are supported by suspension wires 13 , and both are connected by connecting wires 14 . The first and second lower backing plates 11, 12, the connection lead 14, and the suspension lead 13 constitute a metal mounting member in which metal parts are integrally molded. A plurality of inner leads 15 are arranged around the first and second lower backing plates 11 and 12 .

[0028] The first chip 16 has its principal surface overlapped with the first lower substrate 11 and is mounted on the principal surface of the first lower substrate 11 with paste (not shown). ...

Embodiment approach 2

[0052] In this Embodiment 2, if Figure 7As shown, instead of providing markings on the horizontal bars 18 as in the first embodiment, recesses 24 are provided as markings on the connection leads 14 . That is, the mounting member has a connection wire 14 (third portion) that is located between the first and second chips 16, 17 and that connects the first underlayment 11 (first portion) and the second underlayment 12 (second portion). . Further, on the side surface continuous from the first lower backing plate 11 to the second lower backing plate 12 via the connecting wire 14 , a concave portion 24 dented toward the inner side of the side surface is provided. The bottom part of the recess 24 lies at least on the connecting wire 14 . and, if Figure 8 As shown, the first and second chips 16 , 17 are mounted on the lower pads 11 , 12 . Other structures are the same as those in Embodiment 1. In this way, when the chips 16 and 17 are mounted on the lower substrate, the first a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com