Low altitude prefabricated case beam internal mold construction method

A construction method and internal mold technology, applied in the direction of bridges, bridge construction, erection/assembly of bridges, etc., can solve the problems of limited remaining space of external molds, unsuitable methods and structures, and limited construction conditions, so as to improve labor productivity. , the effect of improving working conditions and shortening the prefabrication cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

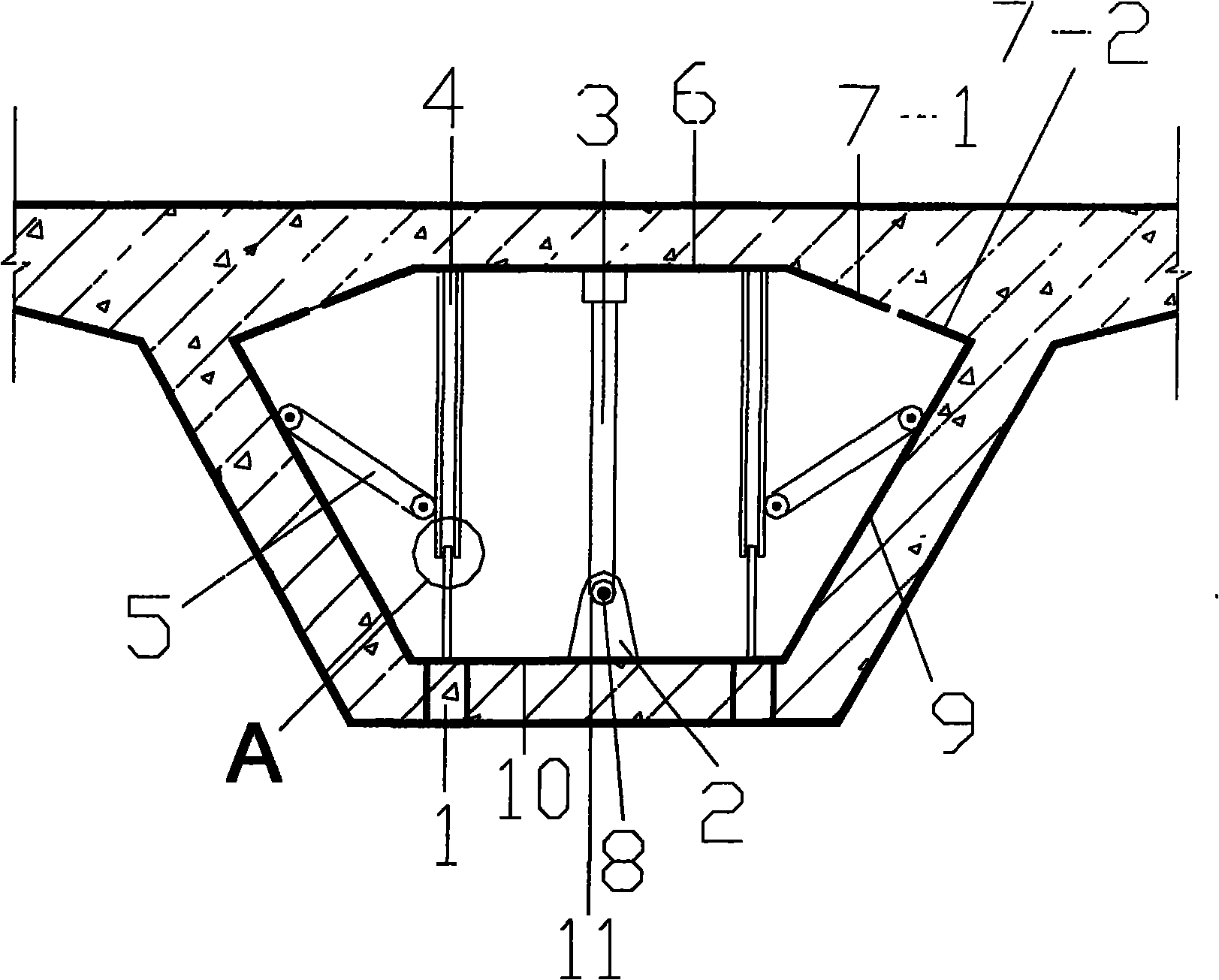

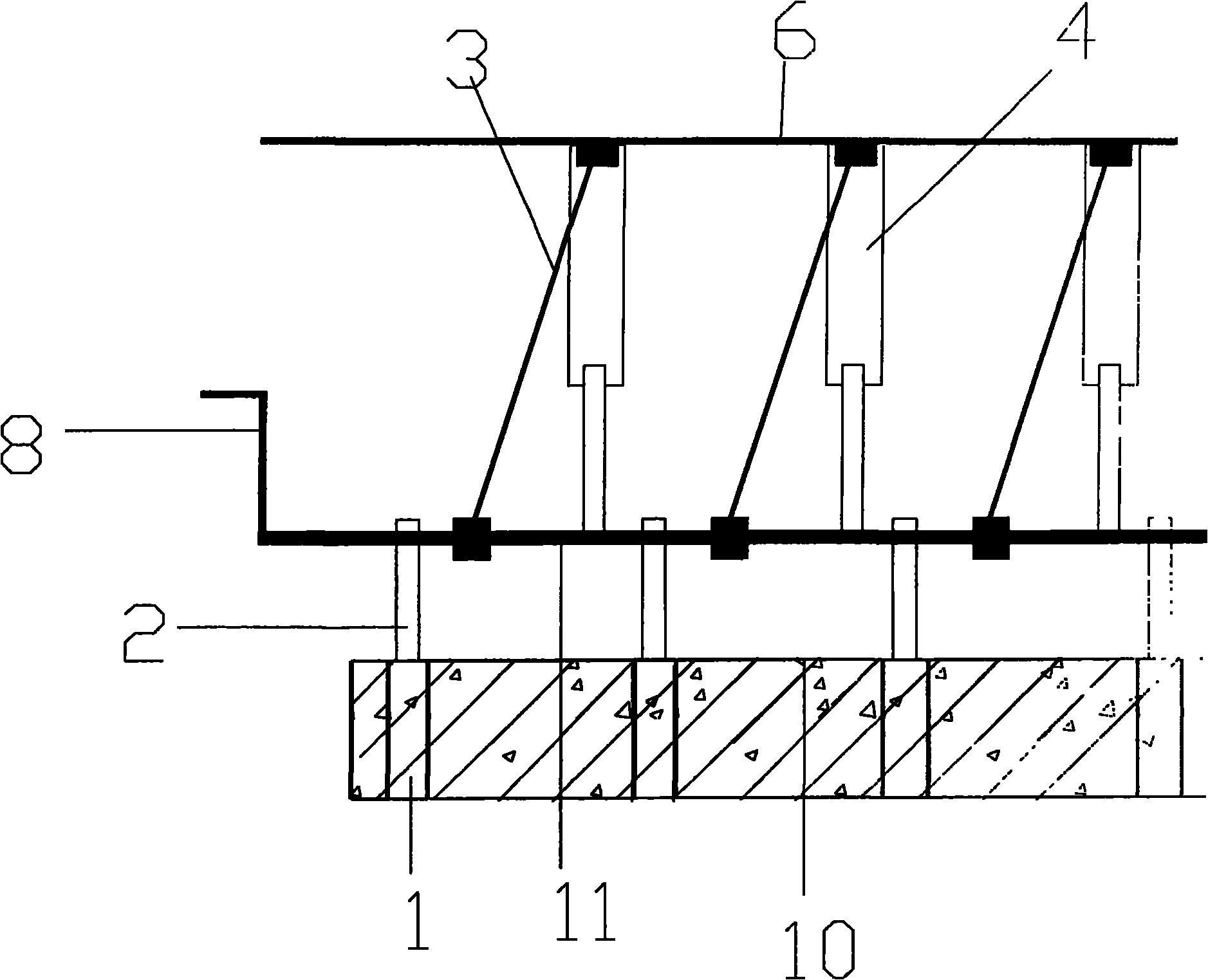

[0022] Concrete is poured in a structure with a width of 260cm, a height of 100cm, and a thickness of 15cm. The construction method is as follows:

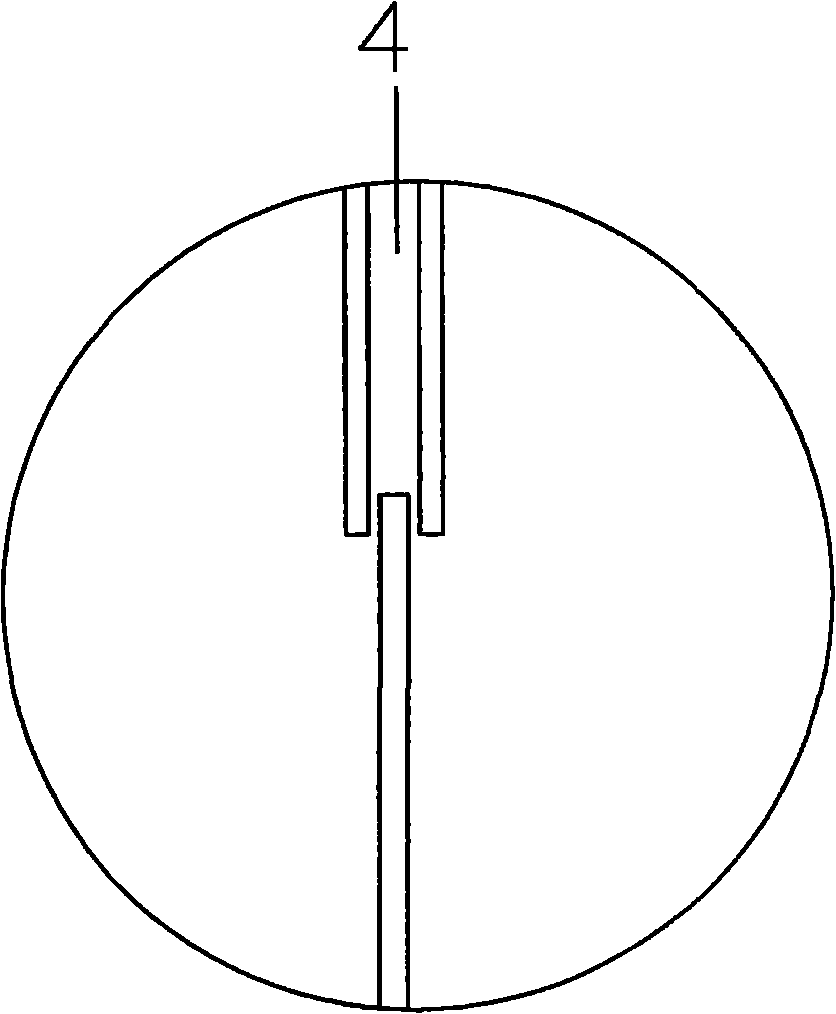

[0023]Prepare the inner and outer molds, connect the ejector rod of the inner mold and one end of the sliding sleeve to the top template respectively, and then pre-assemble the top template, the upper template, the first and the second lower template of the inner mold The external formwork is supported on the concrete platform; the bottom formwork of the internal formwork is fixed by a concrete block support on the bottom formwork of the external formwork, and the concrete strength grade of the cushion block is the same as the concrete strength grade of the box girder, A steel ear plate with a hole is arranged at a certain distance along the bottom template of the inner mold, and a long connecting rod with one end connected to the threaded sleeve is inserted in the hole, and the long connecting rod is connected with the The other ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com