Stator of a rotary electric machine having secured core slot insulators

一种绝缘体、定子铁芯的技术,应用在敷设固体绝缘、绕组绝缘的形状/式样/结构、绕组导体的形状/式样/结构等方向,能够解决困难工艺等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

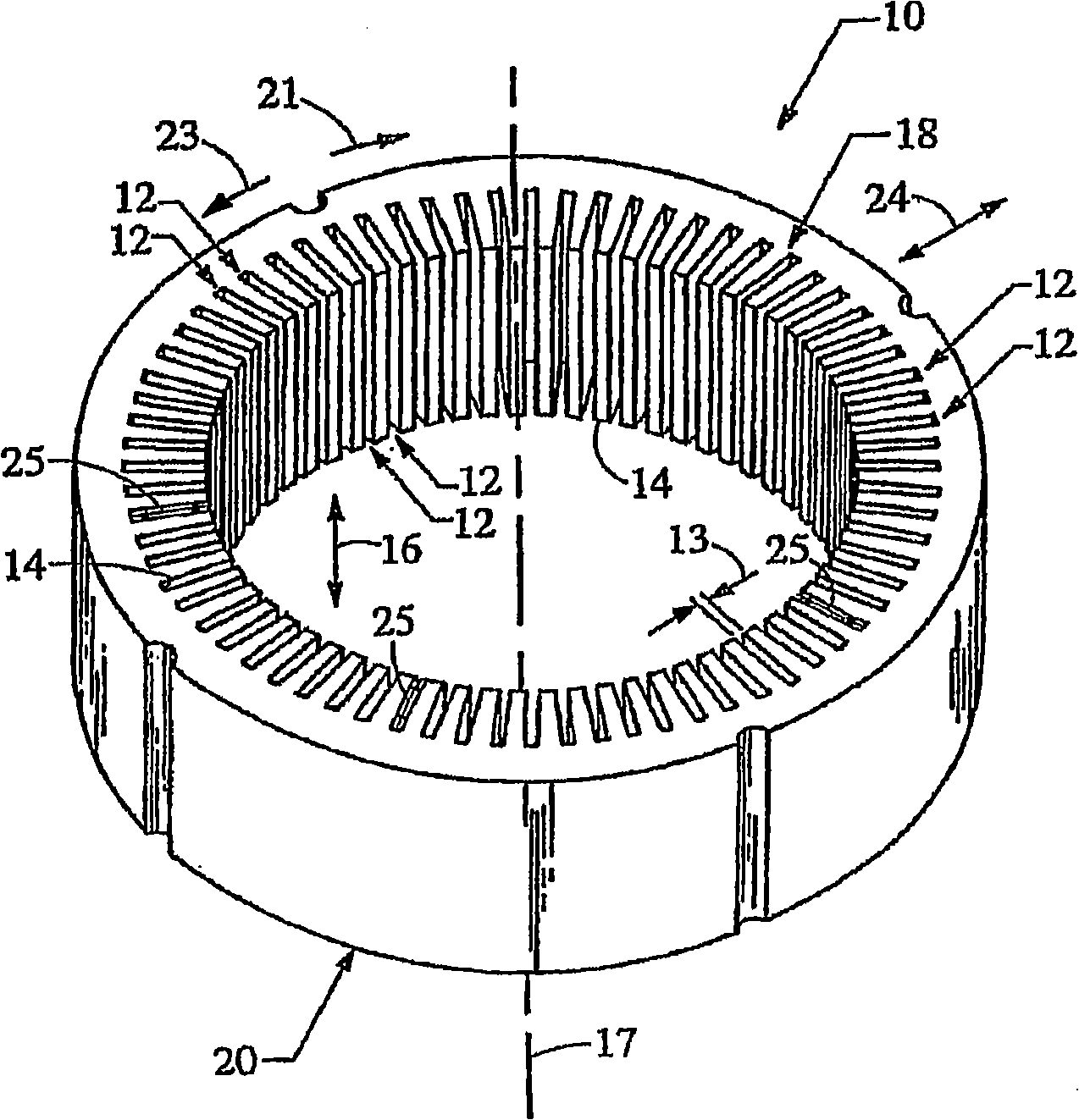

[0025] Refer to figure 1 , The generally cylindrical stator core is indicated as 10 as a whole. The stator core 10 includes a plurality of core slots 12 formed on the inner circumferential surface 14 thereof. The core slot 12 extends axially, as indicated by the arrow 16, and is parallel to the central axis 17 of the stator core 10 at the first end 18 and the second end 20 thereof. The axially upward direction is defined as the moving direction to the first end 18 of the stator core 10, and the axially downward direction is defined as the moving direction to the second end 20 of the stator core 10. Preferably, the iron core slots 12 are arranged equidistantly along the circumferential inner surface 14 of the stator iron core 10, and each inner surface 14 of the iron core slot 12 is substantially parallel to the central axis 17. The clockwise direction of the circle is shown by arrow 21, and the counterclockwise direction of the circle is shown by arrow 23.

[0026] The core slot ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com