Gas appliance

An appliance and connector technology, applied in the field of welding torches or other gas-burning appliances, can solve the problems of difficult, time-consuming and inconvenient welding torch barrels

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

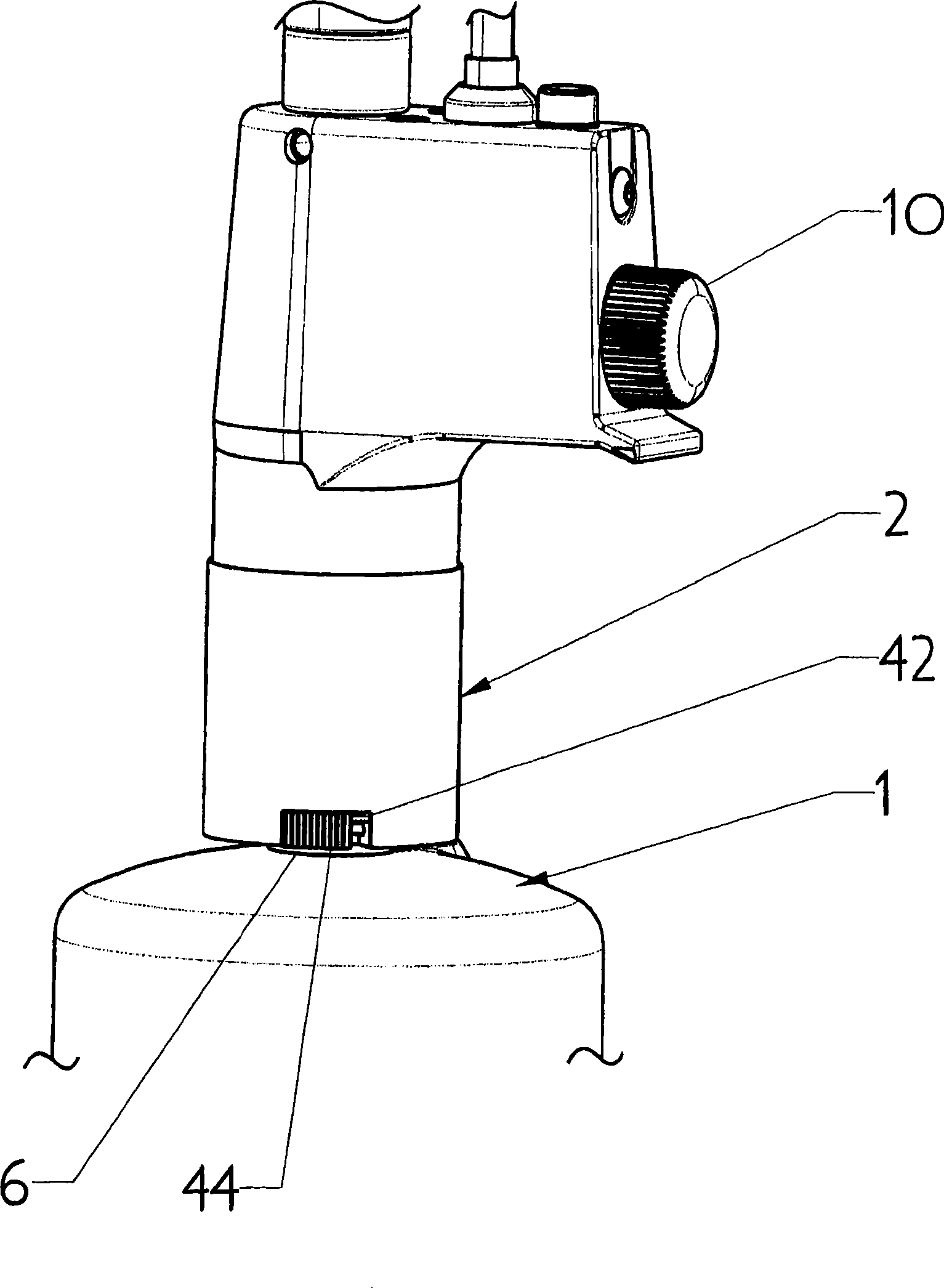

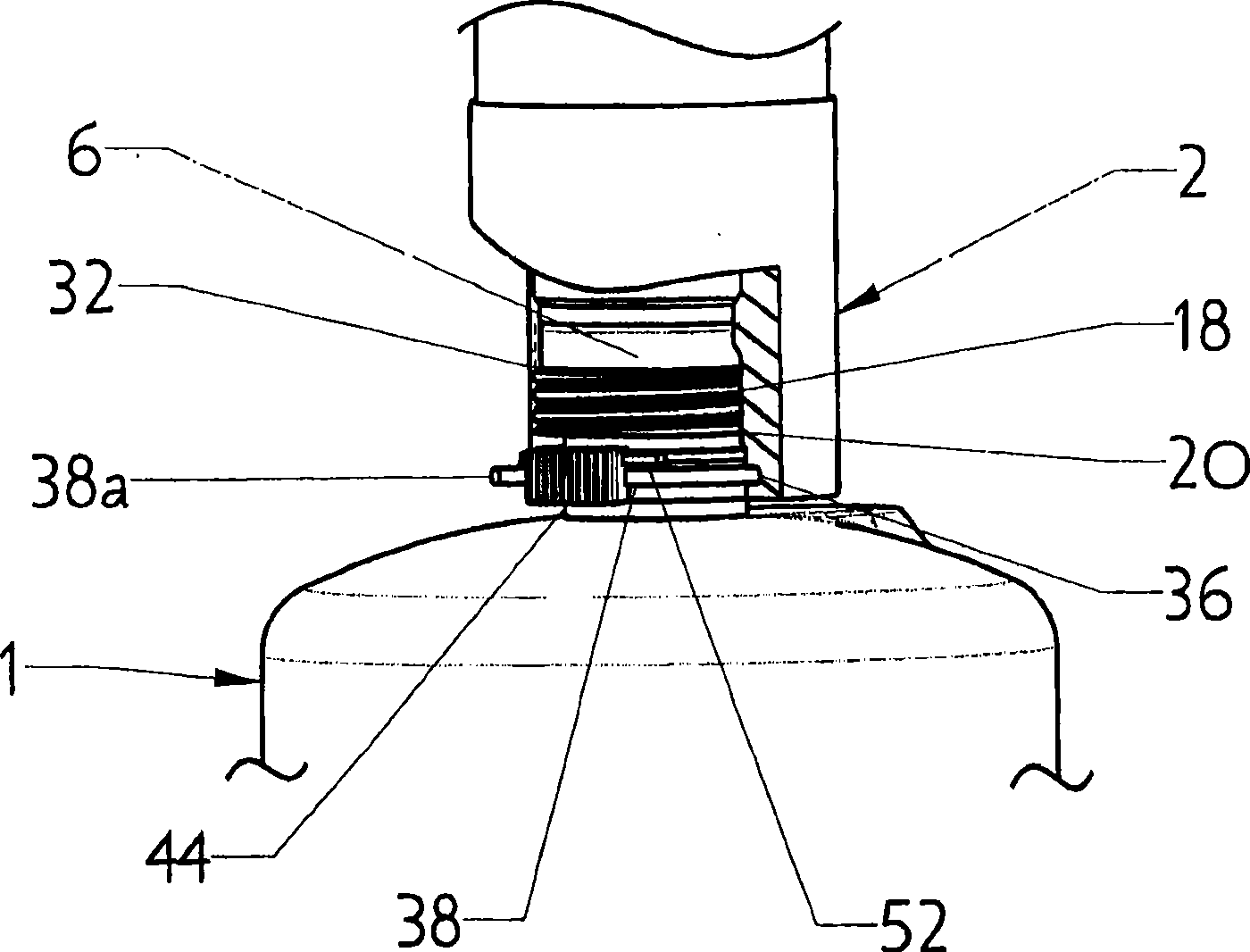

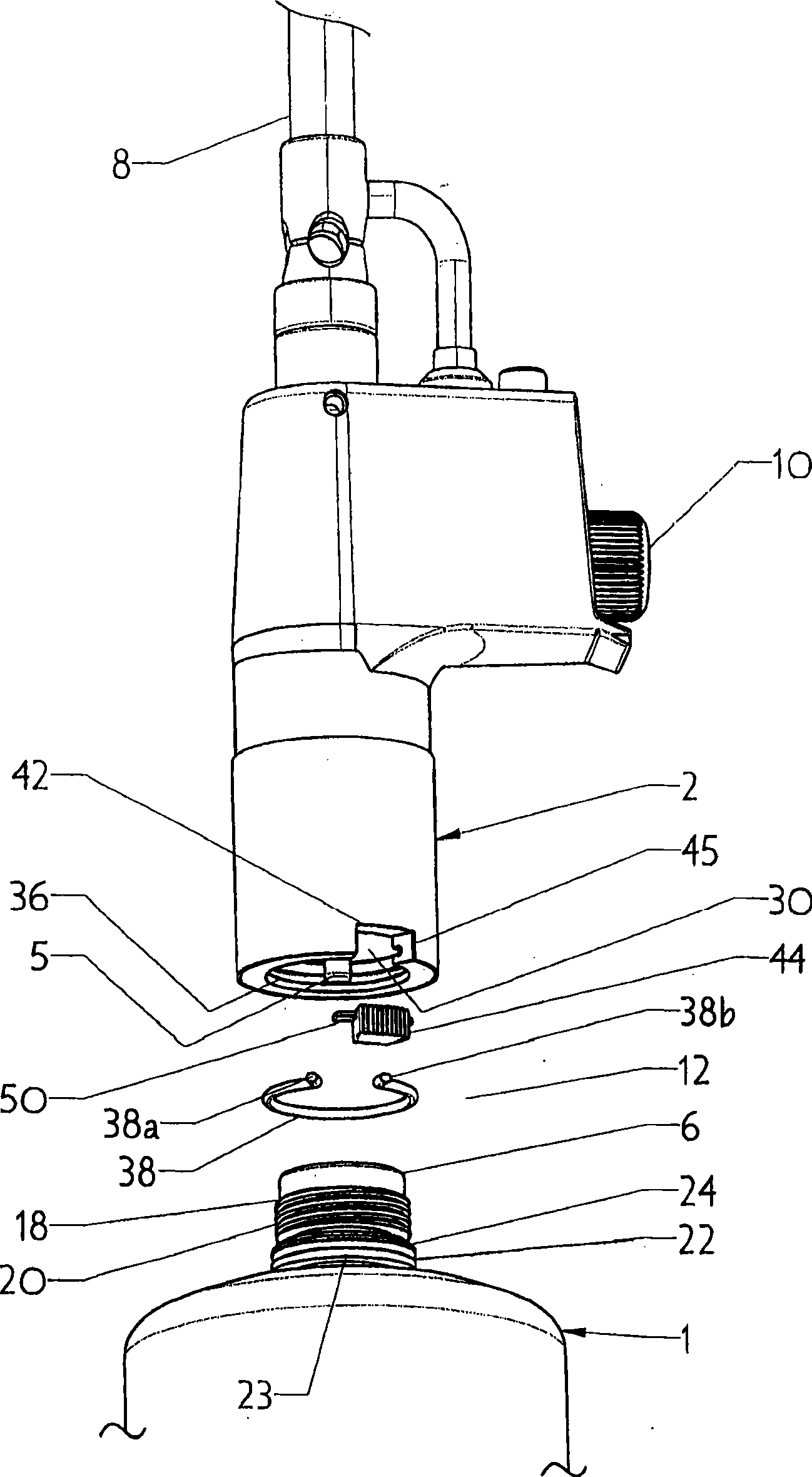

[0010] The figures show a quick connect fitting for connecting a fuel cartridge or tank 1 to an appliance such as a welding torch or torch tube 2 . Tank 1 can hold fuels such as propane, propylene, butane, MAPP gas, etc. The tank 1 includes a port for communicating the inside of the tank 1 with the outside. A first connector 6 is located within the port for connecting the canister 1 into the torch barrel 2, as will be described shortly below. The torch tube 2 includes a valve assembly and a fuel line 5 for controlling the flow of fuel from the canister 1 to the burner tube 8 . The fuel is ignited in the burner tube 8 by eg a piezoelectric igniter 10 . A controller for adjusting the size of the flame is also available. A second connector 12 is secured to the end of the torch barrel 2 for detachable connection to the first connector 6, as will be described below. While the invention is described with particular reference to a welding torch, it is to be understood that the fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com